Operating Instructions - Synchroprint 3000 (Manual-Registration Version)

________________________________________________________________________________

Operating Instructions - Synchrprint 3000 (Manual-Registration Version) V1-1 Page 47 of 49

10. Maintenance of the Synchroprint 3000

The Synchroprint 3000 has been designed to operate ‘maintenance-free’ as far as possible. Only a

few important service measures are necessary by the operator.

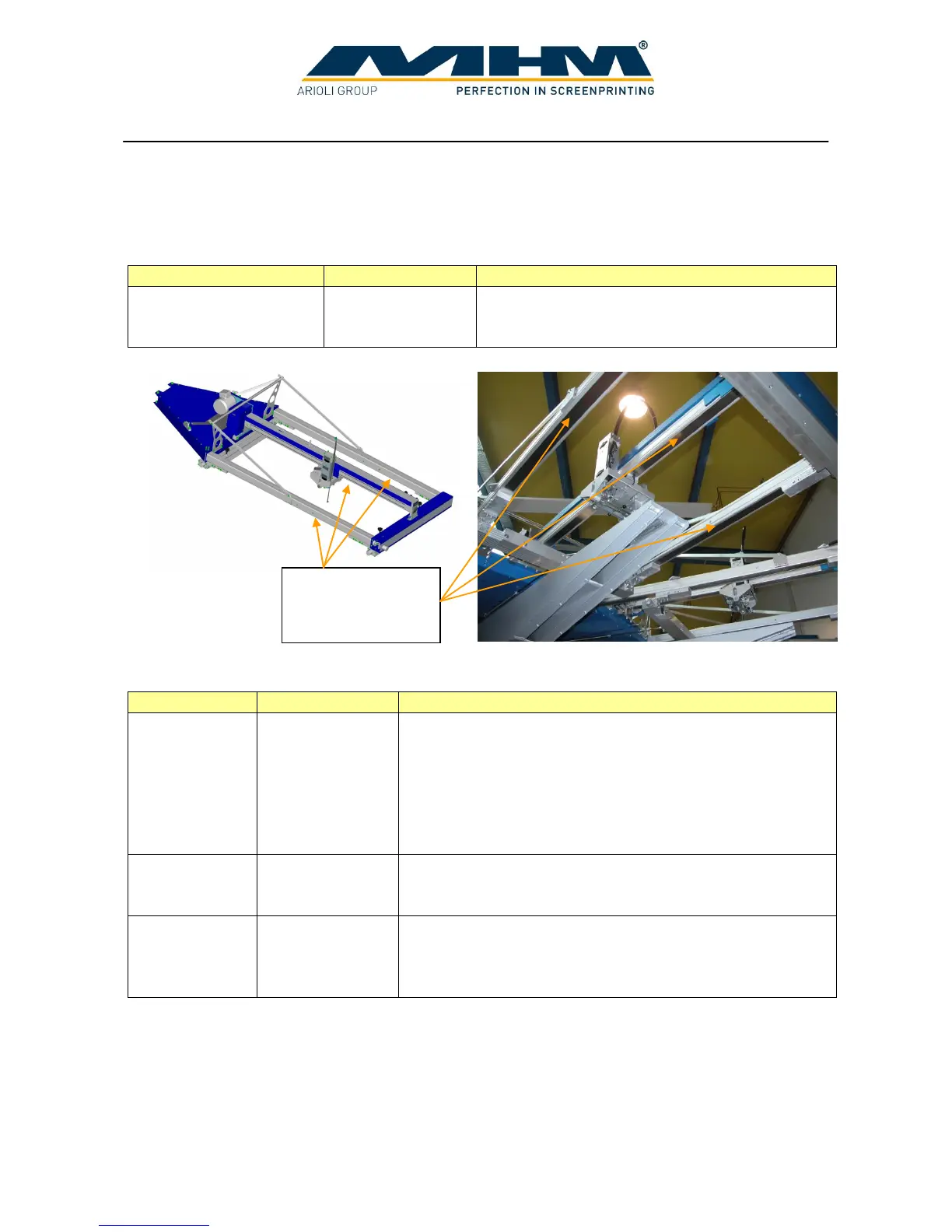

Wipe clean the sealing

band on the underside of

all the linear profiles

The sealing band on the underside of the linear

profiles must be wiped clean thoroughly and

lubricated with an oil-soaked cloth.

Every 2 weeks

for the first 6

months, then

quarterly

thereafter

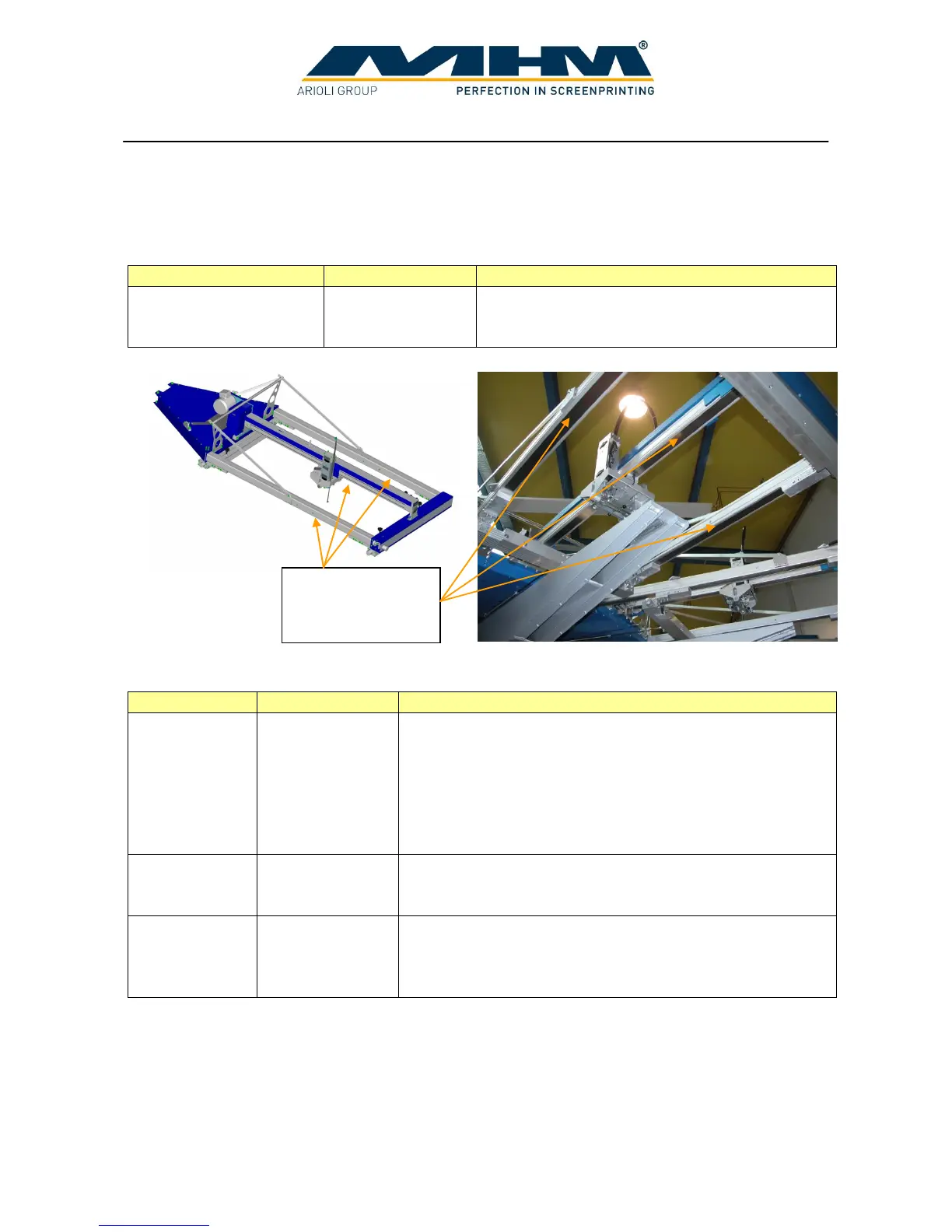

The machine must be lubricated via the grease nipple

located on the centre shaft. MHM recommends “Berner

Heavy-Duty Multi-Purpose Grease” or a comparable grease

with the following technical specifications:

Water-repellent, lithium grease

Minimum melting point of approx. +195° C

Effective lubrication range from -20° C to +120° C

Remove all residues from the Synchroprint 3000 remaining

from production materials such as inks and adhesives etc.

Clean, tidy and sweep the printshop area.

Wash off all anodized parts of the Synchroprint 3000 with

an appropriate cleaner. Clean all inspection glasses and

displays. Clean or replace the protective foil on the touch

screen.

Sealing band on

the underside of

the linear profiles

Loading...

Loading...