Always check unit before applying power (see Sections 8-2 thru 8-11).

TM-246193 Page 64 Invision 352 MPa

Section 8-32. Front Panel/Display Board PC3 Test Point Values (Continued)

Receptacle Pin Type Value

RC50 A Output 23 volts AC RMS at 10 amps; 14−pin remote accessory power

B Input Remote output enable; 0 volts AC = weld output off, 23 volts AC RMS = weld output on

C Output Output signal to remote command reference; +10 volts DC

D GND Remote command reference signal common

E Input Input signal from remote command; 0 to 10 volts DC, +13.5 volts DC when not connected to remote com-

mand from accessory

F Output Current feedback; 1 volt DC per 100 amperes of weld output

G GND 14−pin remote accessory power return

H Output Voltage feedback; 1 volt DC per 10 volts DC of weld output

I* Output 115 volts AC RMS at 2 amps; 14−pin remote accessory power

J* Input Remote output enable; 0 volts AC = weld output off, 115 volts AC RMS = weld output on

K Chassis Power source chassis

L Input Wirefeed command. 0 to +10 volts DC from synergic capable wire feeder

M Input Prior to MA370426A not used. Effective with MA370426A Remote Process Select. When connected to

Remote Process Select capable single wirefeeder; Mig = 3.5 volts DC, Pulse = 2.5 volts DC. When con-

nected to Remote Process Select capable dual wirefeeder; left side Mig = 5.5 volts DC, left side Pulse =

4.5 volts DC, right side Mig = 7.5 volts DC, right side Pulse = 6.5 volts DC

N Input Wire feed speed common

No testing required for remaining plugs and receptacles.

* 115 volts AC not available at RC50 eff w/ME224001U.

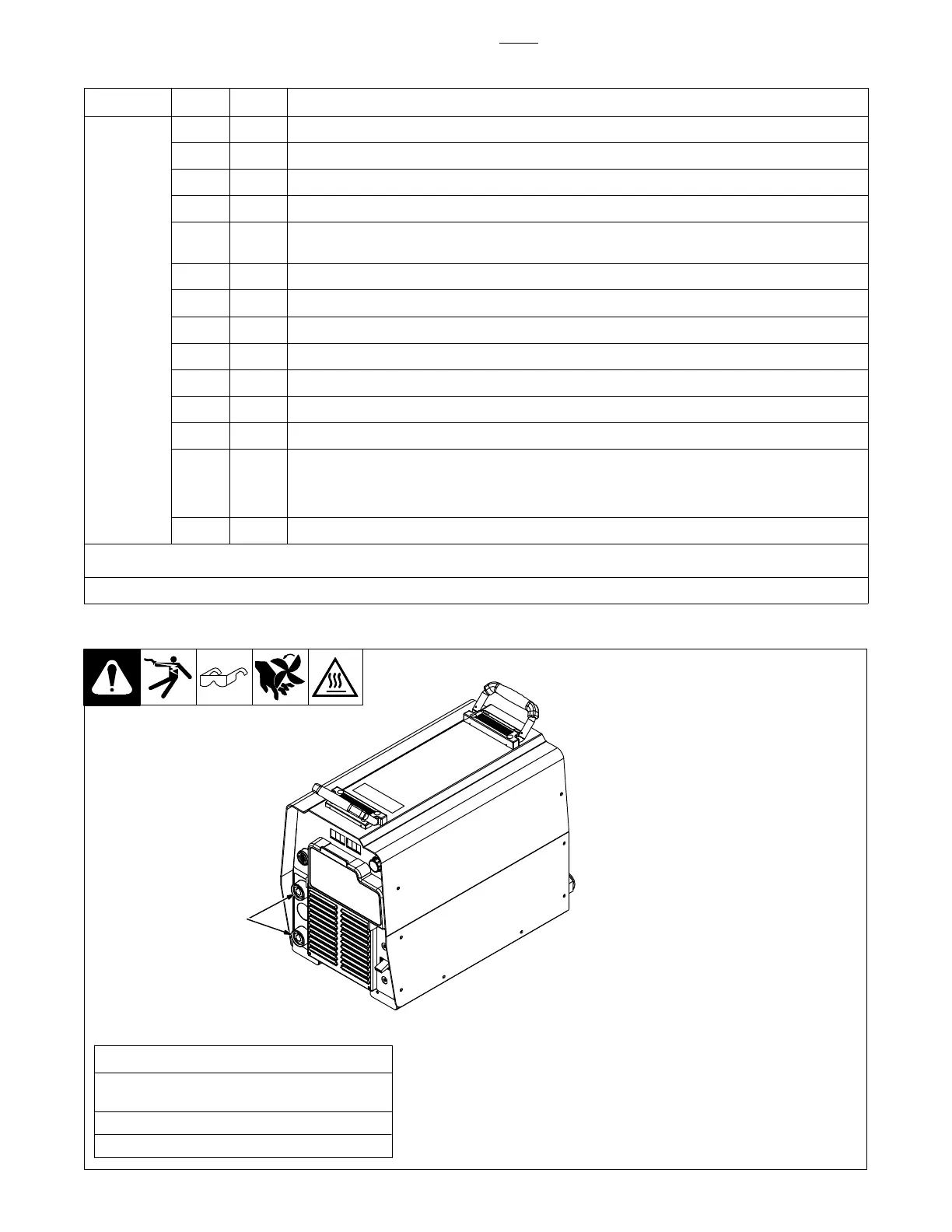

8-33. Checking Unit Output After Servicing

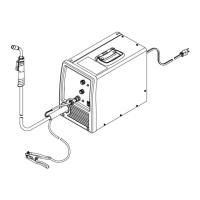

1 Weld Output Terminals

Check open-circuit voltage be-

tween terminals according to Sec-

tion 8-18 (voltage V-12)

If correct voltage is not present,

repeat troubleshooting procedures.

Perform a load bank test to en-

sure welding generator oper-

ates properly after servicing.

Be sure load bank is capable of

handling the rated output of the

welding generator being tested

(see load bank Owner’s Manu-

al).

The load bank will simulate a

weld load and the electrical de-

mand on the unit. See Specifi-

cations section for rated load.

If unit does not perform at rated

load, repeat troubleshooting

procedures.

Complete pre-operational checks.

Reinstall cover and side panels.

1

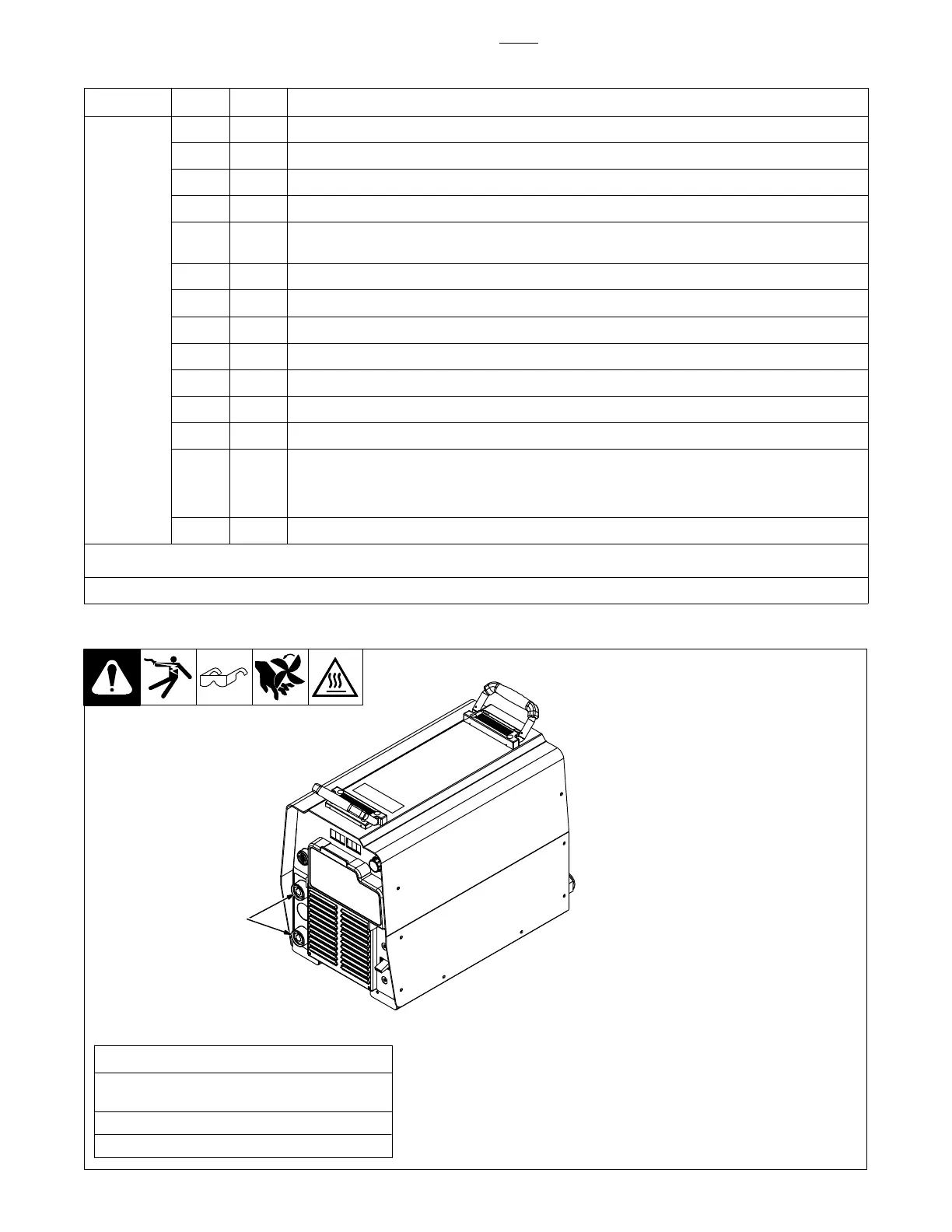

Check Unit Static 2018-12 - 803691-E

Pre-Operational Checks

Check labels; replace labels that are unreadable or

damaged (see Parts List).

Clean weld output terminals. Tighten connections.

Clean outside of entire unit.

Loading...

Loading...