© 2009 MIMAKI ENGINEERING CO.,LTD.

Maintenance Manual Change Tracking P.4

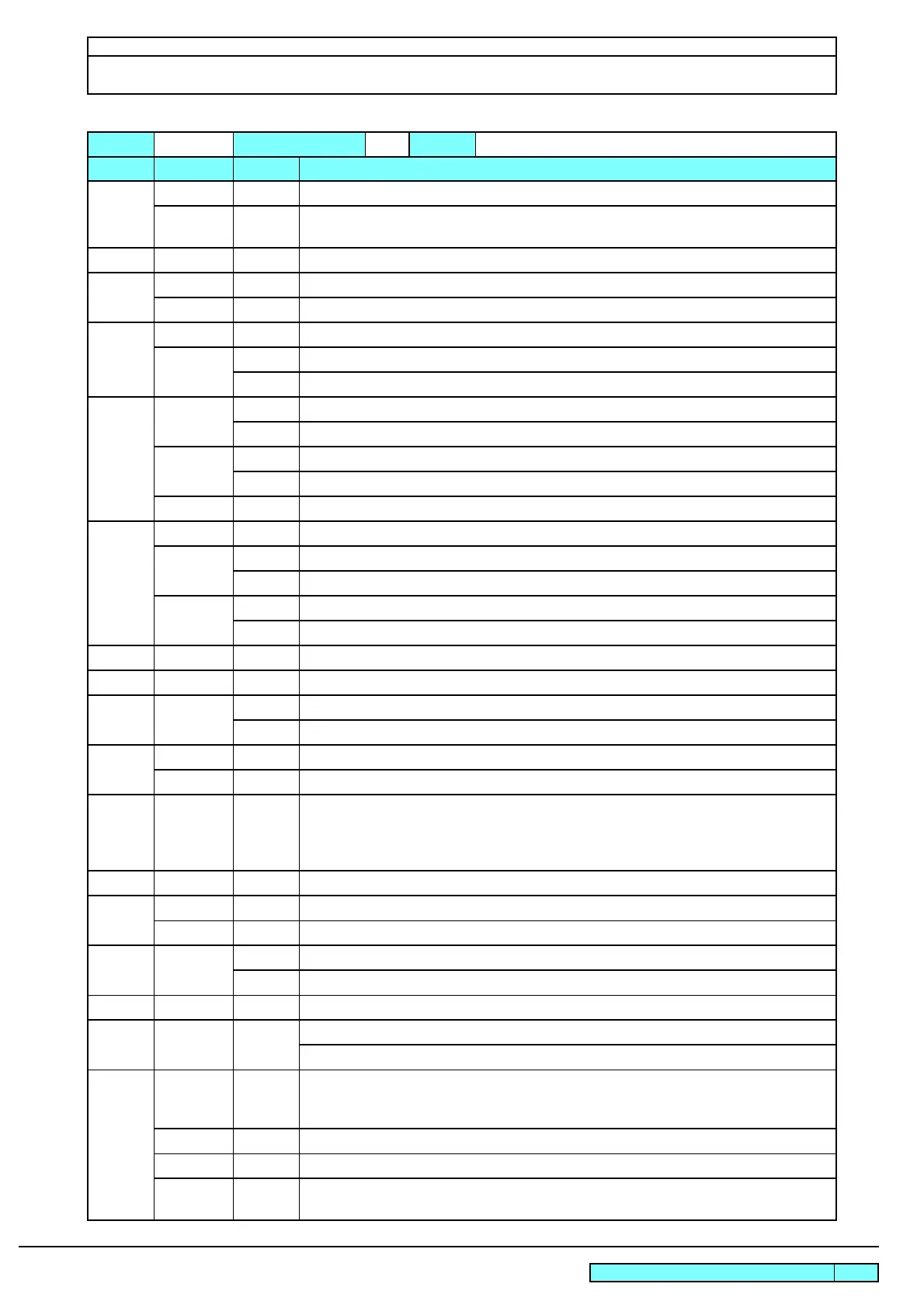

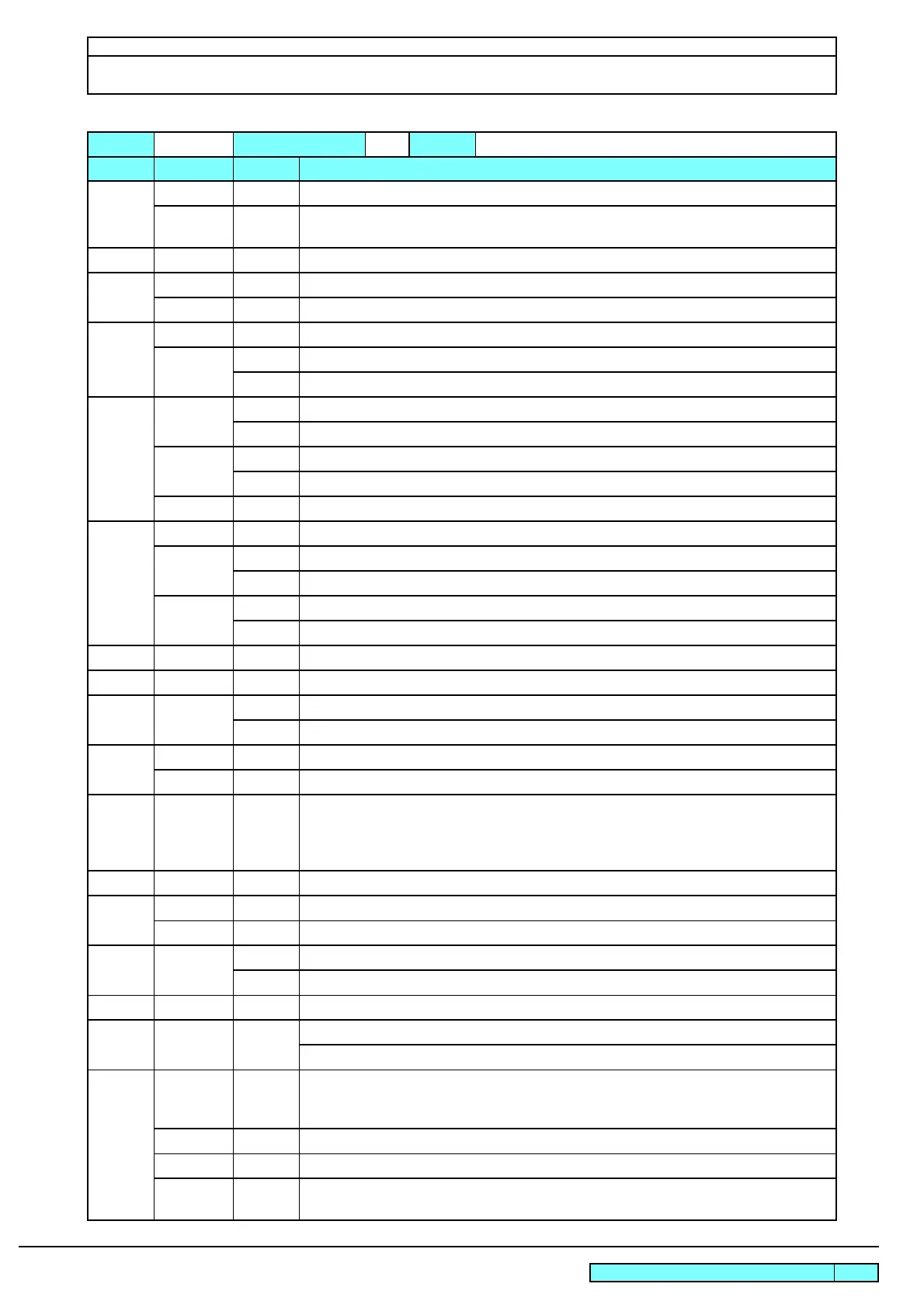

Service Documents > Maintenance Manual Change Tracking

Maintenance Manual Change Tracking

3.1.2 Revised 1.10 Work operation 1: “station cover U and ...” “station cover U, W ink guard and ...”

Revised 1.10 Work operation 3: “... while it is pressed against the innermost part.”

“... while pushing it toward you.”

3.1.3 Revised 1.10 Work operation 1: “Remove the ICU cover F, ICU cover R, ...” “Remove the ICU cover, ...”

3.1.4 Revised 1.10 Section changed: “3.3. Driving Parts” “3.1. Ink Related Parts”

Revised 1.10 Work operation 1: “... C station cover.” “... C station cover 2.”

3.2.1 Added 1.10 Work operation 4: “In installation, pay attention to harness treatment.”

Revised 1.10 Work operation 7: “7.0 mm” “8.8 mm”

1.10 Work operation 8 to 10: The order of work items changed and items added

3.2.2 Revised 1.10 Work operation 1: “... auto cutter assy.” “... S guide.”

1.10 Work operation 4: “7.0 mm” “8.8 mm”

Added 1.10 Work operation 4: “(If necessary, check to see if the magnet catcher...”

1.10 Work operation 6: “Install the S guide while pushing it to the left.”

Erased 1.10 Caution Box: “Be sure to wear protective glasses and working gloves...”

3.2.3 Added 1.10 Work operation 4: “Set the pressure of all the clamps to Middle,...”

Revised 1.10 Work operation 6: “Adjust the pen stroke at...” “Adjust so that the pen stroke is...”

1.10 Work operation 7: “7.0 mm” “8.8 mm”

Added 1.10 Work operation 11, 12

1.10 Important Box: “Once the S guide is removed, ...”

3.3.2 Added 1.10 Work operation 1: “...and D BKT cover.”

3.3.3 Erased 1.10 Work operation 4: “Greasing of Y drive belt”

3.3.5 Added 1.10 Work operation 5: “GR/PR adjustment”

1.10 Work operation 6: “Install all the covers temporarily first ...”

3.4.1 Revised 1.10 Work operation 3/4: “Mounting” / “Removal”

Erased 1.10 Caution Box: “Be sure to wear protective glasses and working gloves...”

4.1.1 Erased 1.10 Adjustment item:Adjustment of light pointer offset

Adjustment of cutting position

Work contents: Pulley BTG removal or replacement

Paper sensor

4.2.2 Added 1.10 Tips Box: “The same adjusted value is applied to...”

4.2.3 Added 1.10 Important Box: “Make adjustment with [EXPANDS] of...”

Erased 1.10 Tips Box: “If the unit is changed to inch,...”

4.2.5 Revised 1.10 Adjustment procedure 4: “Vertically shifts the cap.” “Shifts the cap.”

1.10 Adjustment procedure 5: “Horizontally shifts the head.” “Horizontally shifts the wiper.”

4.2.8

Page deleted

– “Remarks” and “Examples of inputting a compensation value”

4.2.9 Revised 1.10 Function: “400g” “350g”

Procedure 6: “400g” “350g”

4.2.10 Revised 1.10 Function:

“Plots 11 square patterns using the 11 pen landing values of 0 to 200, respectively. (20 steps)”

“Plots 11 square patterns at the positions of different pen landing values in steps of 20, start-

ing at the first pen landing point.”

Added 1.10 Function (The content of adjustment...): “#LANDING UP POSITION”

Added 1.10 Procedure 3 to 6: Because of addition of “#LANDING UP POSITION”

Revised 1.10

Procedure 7: “... the 11 pen landing values (0, 20, 40 ... 200) of 0 to 200 currently being set.”

”... different pen landing values in steps of 20, starting with the currently set pen landing value.”

Date 2008.09.17 Manual Ver. 1.10 Remark

Index Status Rev. Changes

Loading...

Loading...