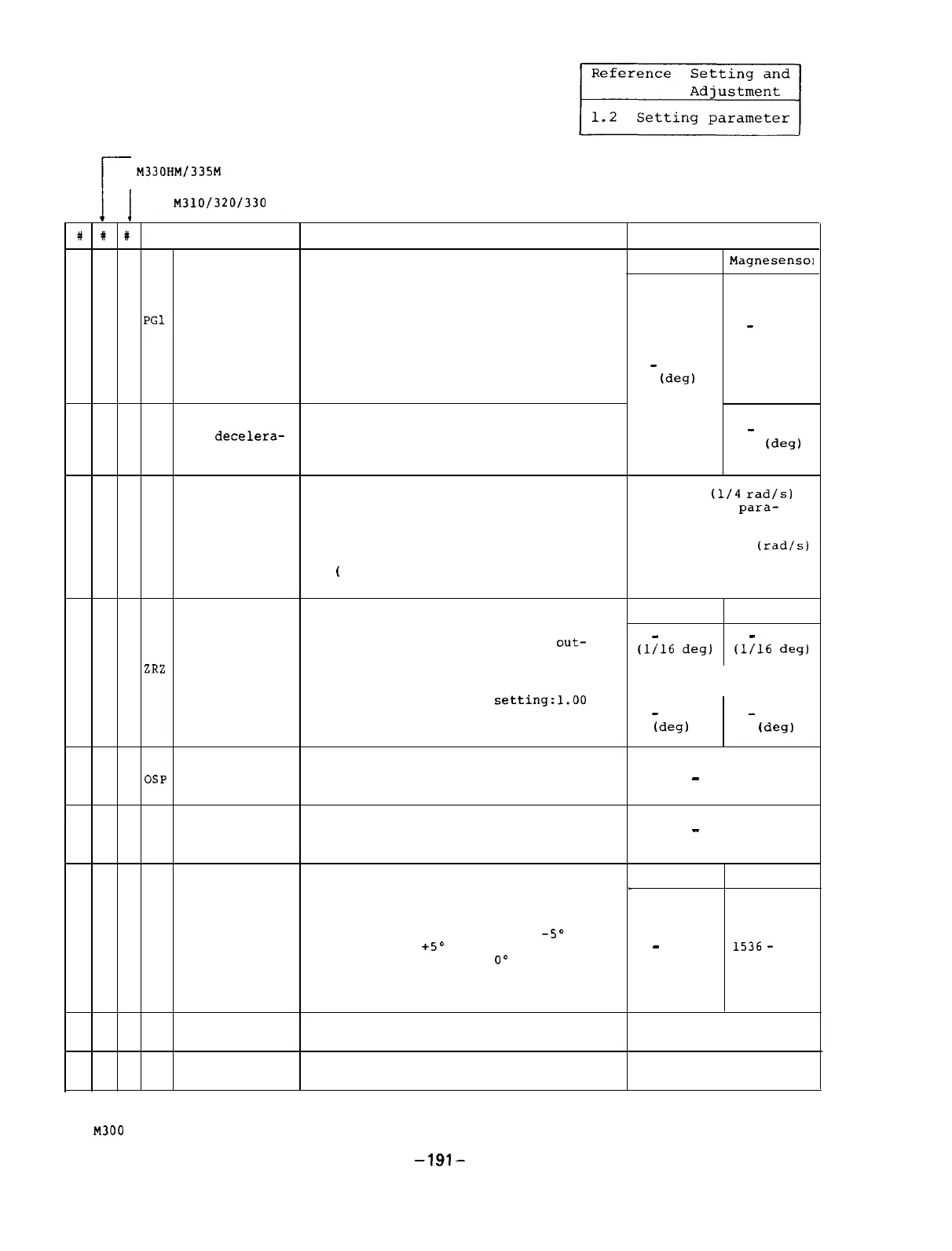

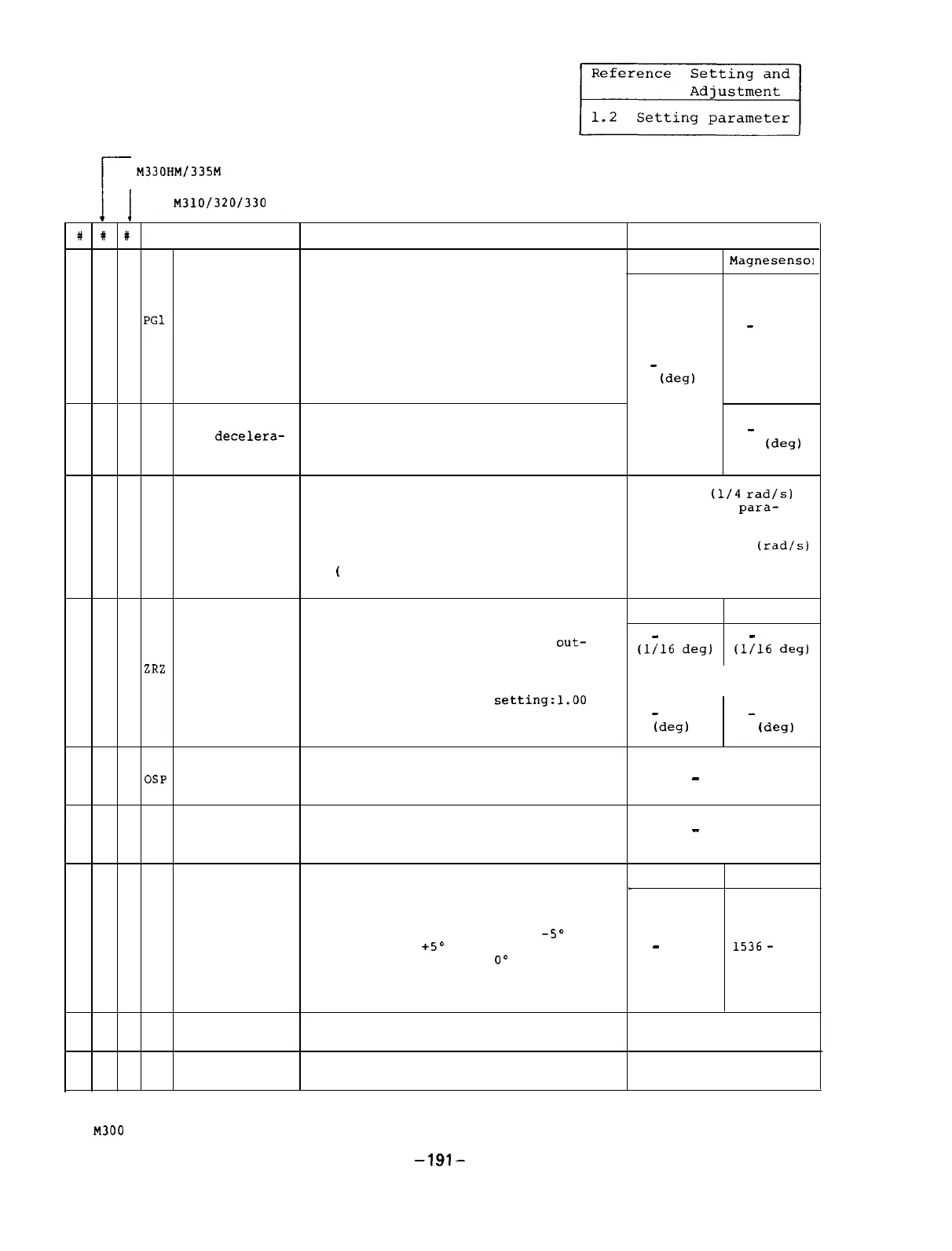

r

Parameter No.

on the NC screen when the equipment is linked with

u330~~/335~

through the bus:

r

Parameter No.

on the NC screen when the equipment is linked with

M310/320/330

through the bus:

#

#

x

Parameter Description Setting range (Unit)

Encoder orientation:

Encoder

Magnesenso1

The angle of the creep speed is set.

Orientation

Standard setting: 180

21 33

1

PGl

1st decelera-

tion point

Magnesensor orientation:

0

-

500 ms

The time taken for start of creep

speed after passing over linear zone

is set.

0

-

359

Standard setting: 133

(deg)

Orientation

The angle at which creep speed for

22 34

2 PG2

2nd

decelera-

position loop state is set.

0

-

40

tion point

(deg)

Standard setting: 20

The position loop gain of the spindle

1 to 512

(l/4

rad/s)

in synchronous tap state is set.

However,

the

para-

Synchronous

It should conform with the position

meter of the NC screen

23 35 3 PGC

tap position

loop gain of the feed axis in the

is in the range from

loop gain

synchronous tap state.

0.01 to 999.99

(rad/s)

(

NC

screen standard setting:

15.00)

Encoder

Magnesenso

The position error range where the

orientation complete signal is

out-

1

-

5760

1

-

512

Orientation put is set.

(l/16

deg)

(l/16

deg)

24 36

4

ZRZ

in-position

range

Standard setting: 16

The parameter on NC

screen is as follows:

NC screen standard

setting:l.OO

0

-

359

0

-

39

(deg)

(deg)

25 37

5

OSP

Orientation

The orientation speed is set.

speed

Standard setting: 220

0

-

1000 rpm

26 38

6 CSP Creep speed

The creep speed is set.

0

-

1000 rpm

Standard setting: 20

The orientation stop position is set.

Encoder

Magnesenso

_

Encoder: A value where 360“ is

divided into 4096 is set.

27 39

7 PST

Position shift

Magnesensor:

The angle from

-So

to

+5o

is divided into

0

-

4095 1536- 2560

1024 and

0'

is treated

as 2048.

Standard setting:2048

28 40 8 BRC

Not used.

0 should be set.

29

Not used.

0 should be set.

Continued on the next page.

* The parameters being asterisked are

set from the NC when the equipment is linked with the

M300

series machine through the bus line.

-191-

Loading...

Loading...