MPI – On-vehicle Service

13-33

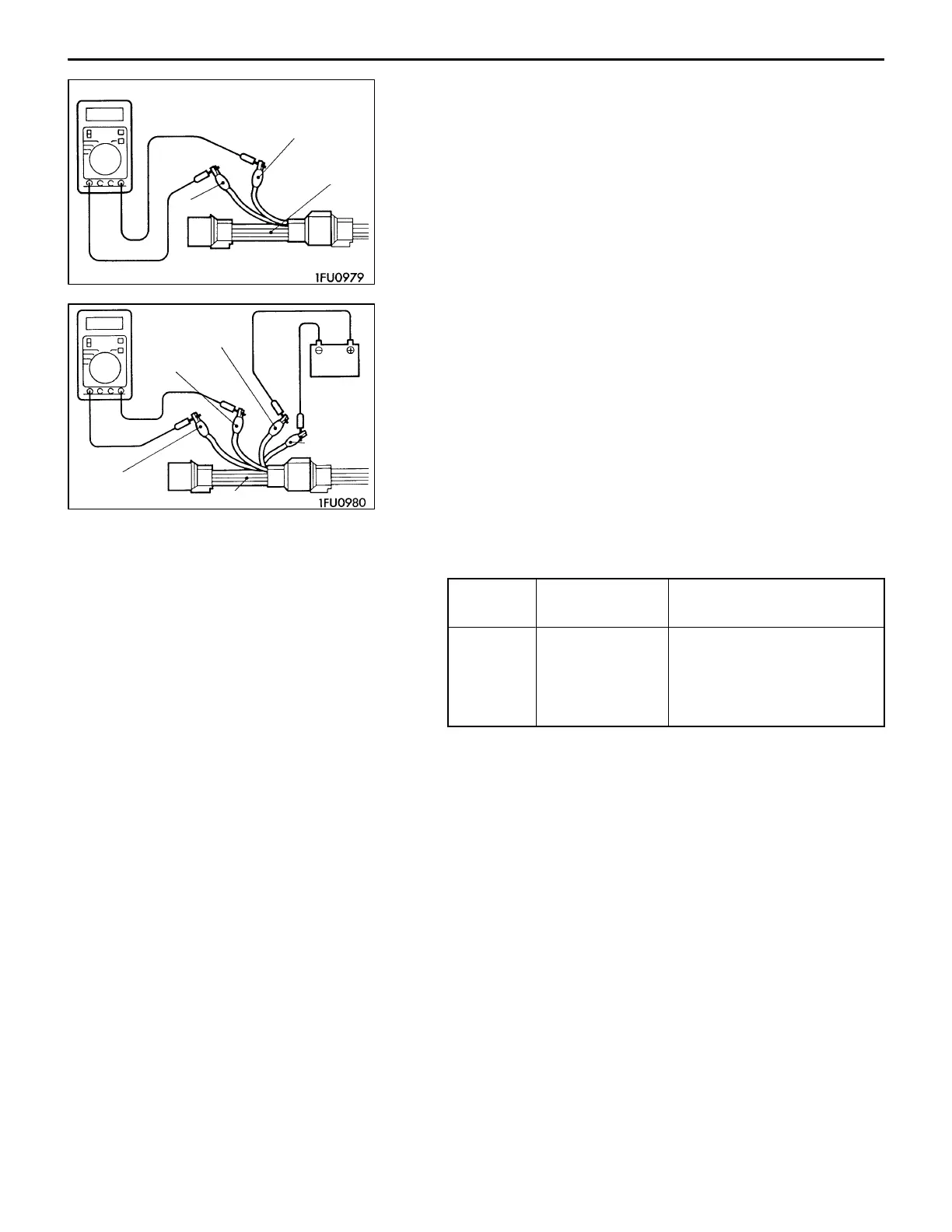

(2) Check that there is continuity (11 to 18 Ω at 20_ C) across

terminal no. 1 (special tool red clip) and terminal no. 3

(special tool blue clip) of the oxygen sensor connector.

(3) If there is no continuity, replace the oxygen sensor.

(4) Run the engine until the engine coolant temperature

exceeds 80_C.

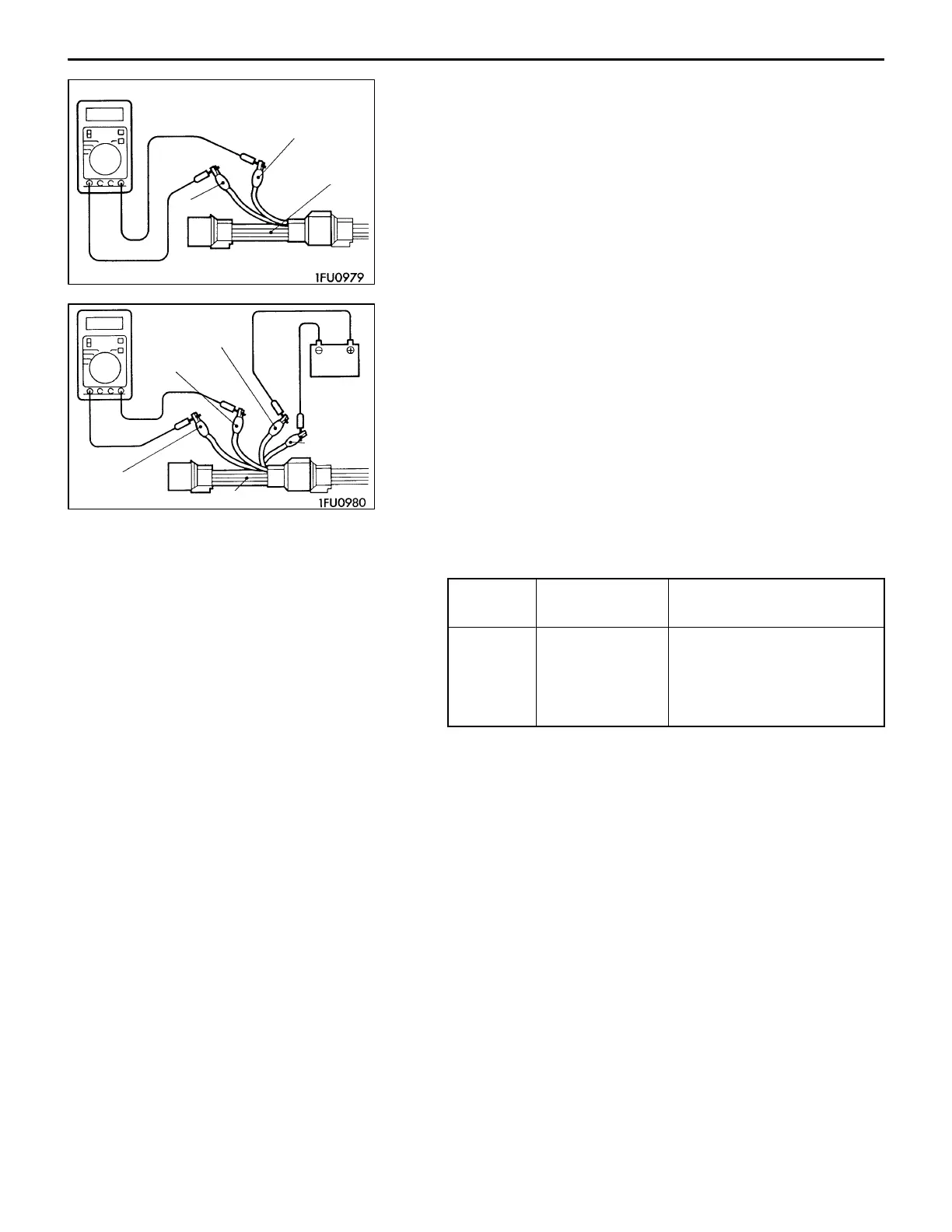

(5) Using jumper wires, connect oxygen sensor terminal no.

1 (special tool red clip) and terminal no. 3 (special tool

blue clip) to battery (+) and (–) terminal, respectively.

Caution

Make sure of the correct connections: if a wrong

connection is made, a broken oxygen sensor results.

(6) Connect a digital voltmeter between terminal no. 2 (special

tool black clip) and terminal no. 4 (special tool white clip).

(7) Race the engine repeatedly to measure the oxygen sensor

output voltage.

Standard value:

Engine Oxygen sensor

output voltage

NOTE

When

engine is

raced

0.6 – 1.0 V When engine racing is

repeated to enrich air-fuel

ratio, an operational oxygen

sensor should output a volt-

age of 0.6 to 1.0 V.

NOTE

Use the same procedures to remove and install the oxygen

sensor.

Red clip

Blue clip

MD998464

Red clip

Blue clip

MD998464

Black clip

White clip

Loading...

Loading...