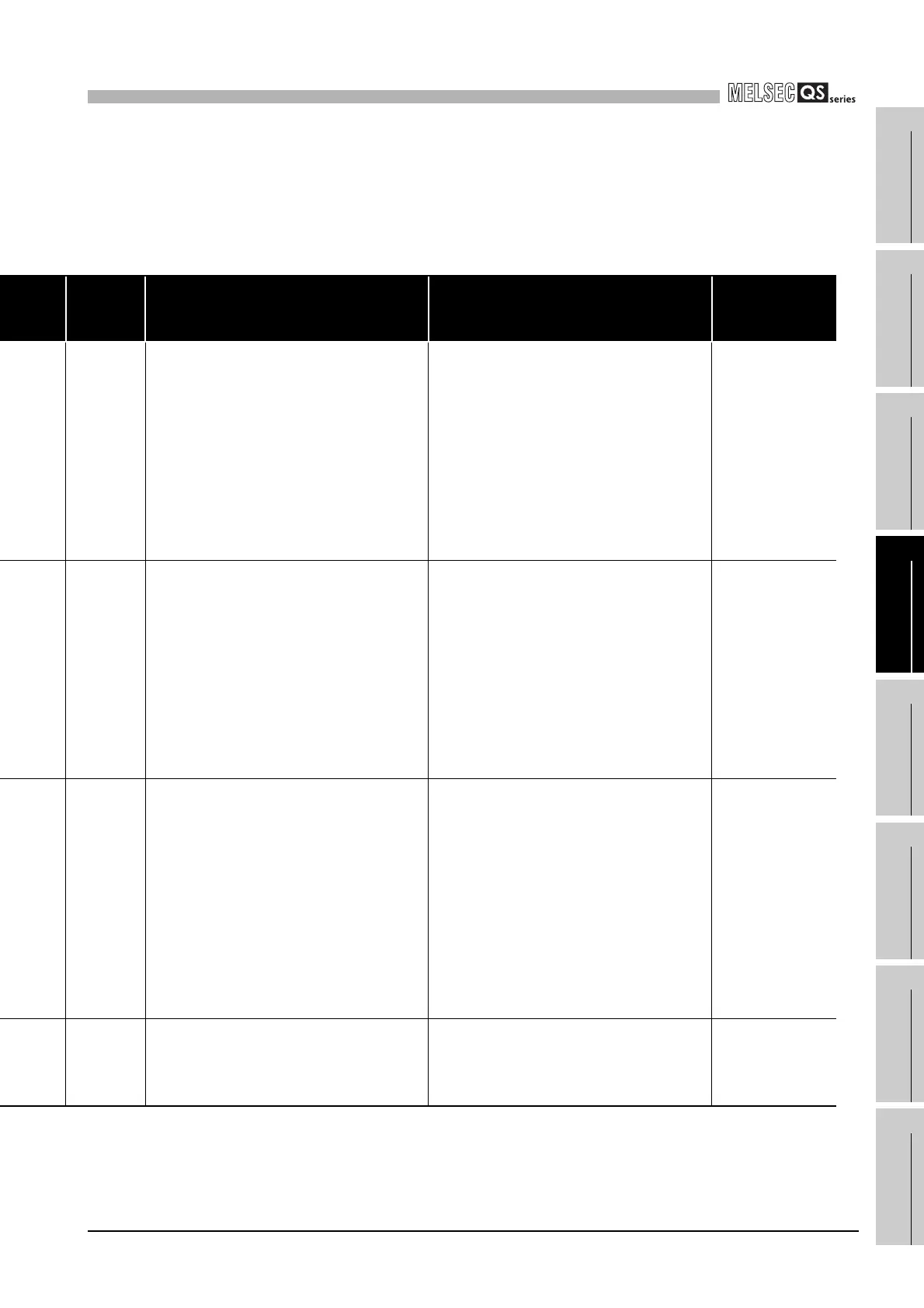

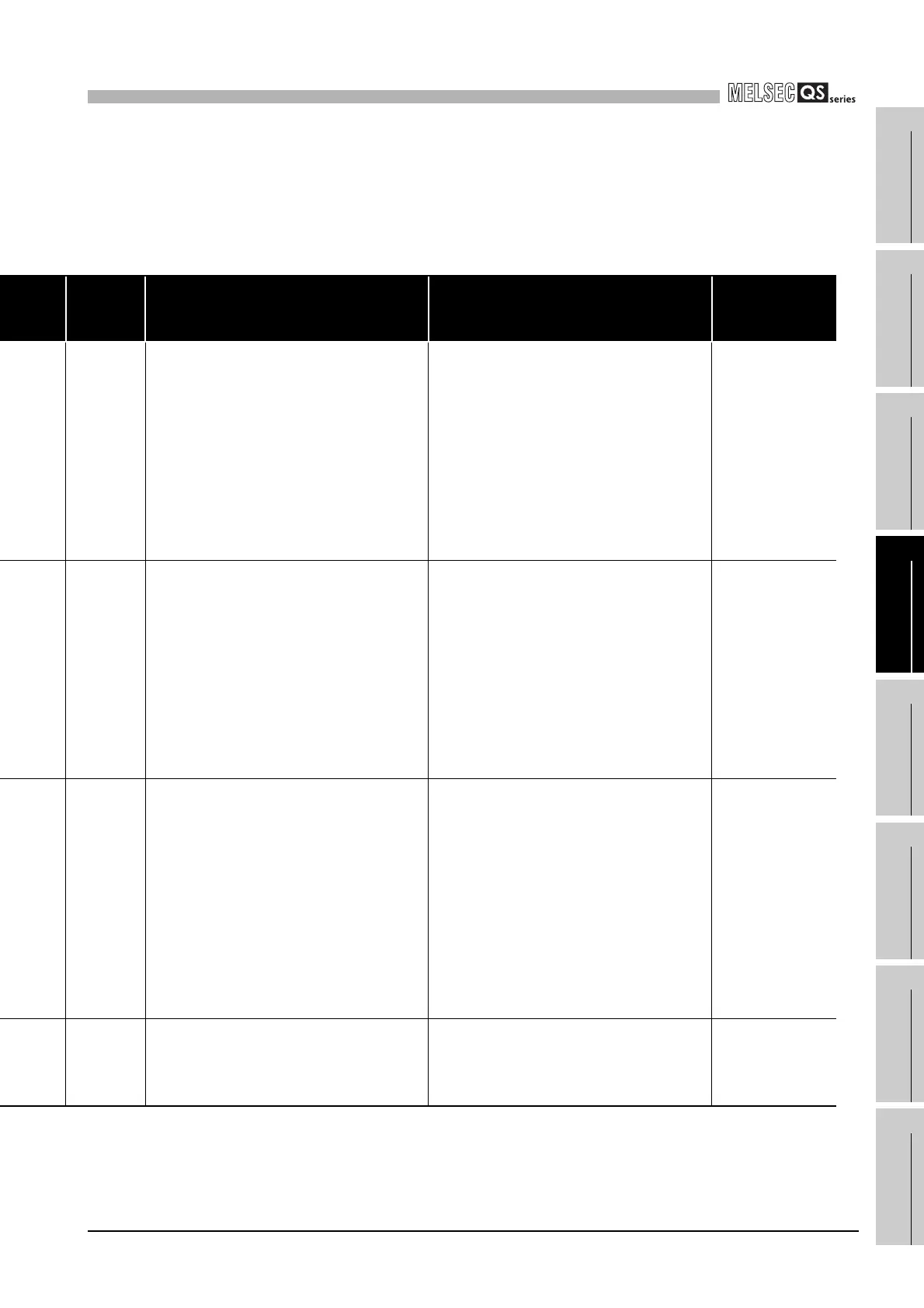

12

TROUBLESHOOTING

12.3 Error Code List

12.3.4 Error code list (2000 to 2999)

12 - 29

9

EMC AND LOW

VOLTAGE

DIRECTIVES

10

LOADING AND

INSTALLATION

11

MAINTENANCE AND

INSPECTION

12

TROUBLESHOOTING APPENDICES INDEX

Error

Code

(SD0)

Error Contents and Cause Corrective Action

Corresponding

CPU

2000

• Intelligent function module

information at power ON are

changed.

• During operation, Intelligent function

module are not installed properly or

installed on the base unit.

Read the common information of the

error using the GX Developer, and

check and/or change the module that

corresponds to the numerical values

(module number) there.

Alternatively, monitor the special

registers SD 150 to SD 153 at a GX

Developer, and change the fuse at the

output module whose bit has a value of

"1".

QS

2100

• In the parameter I/O allocation

settings, an Inteli (intelligent function

module) was allocated to a location

reserved for an I/O module.

• In the I/O assignment setting of the

PLC parameter dialog box, the

number of points assigned to the

intelligent function module is less

than the number of points of the

mounted module.

Reset the parameter I/O allocation

setting to conform to the actual status of

the intelligent function module.

QS

2106

• More than three CC-Link Safety

master modules are mounted.

• More than two CC-Link IE controller

network modules are mounted.

• More than two MELSECNET/H

modules are mounted.

• More than two Ethernet modules are

mounted.

• A module that the Safety CPU

module cannot recognize has been

mounted.

• Mount two or less CC-Link Safety

master modules.

• Mount either only one CC-Link IE

controller network module or

MESECNET/H module.

• Mount only one Ethernet module.

• Mount a module supported in the

Safety CPU module.

QS

2107

The start X/Y set in the PLC

parameter’s I/O assignment settings is

overlapped with the one for another

module.

Make the PLC parameter’s I/O

assignment setting again so it is

consistent with the actual status of the

intelligent function module.

QS

Loading...

Loading...