11 - 4

11.2 Periodic Inspection

11

MAINTENANCE AND INSPECTION

11.2 Periodic Inspection

The items that must be inspected one or two times every 6 months to 1 year are listed

below.

When the equipment is moved or modified, or layout of the wiring is changed, also perform

this inspection.

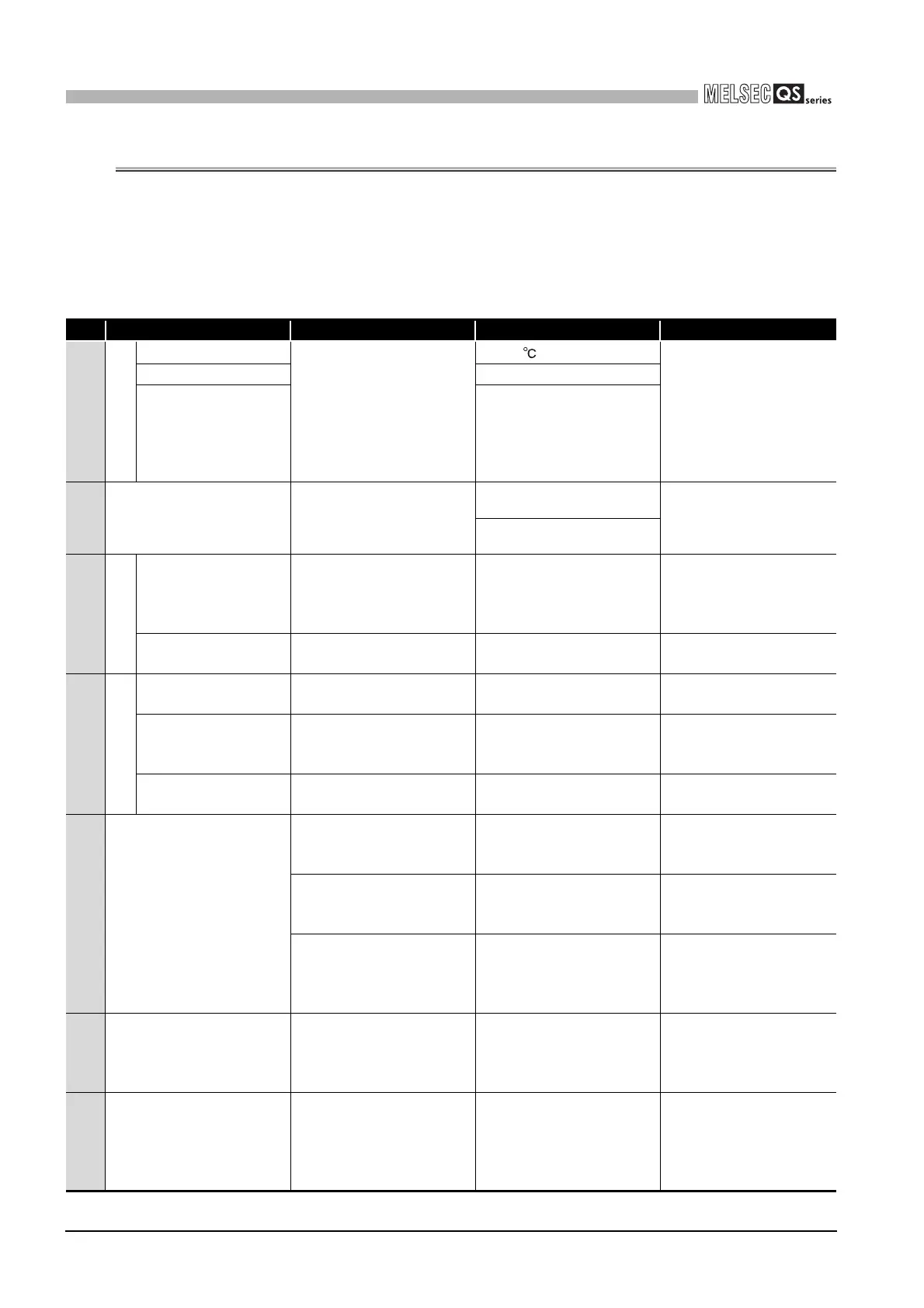

Table11.2 Periodic Inspection

Item Inspection Item Inspection Judgment Criteria Remedy

1

Ambient environment

Ambient temperature

Measure with a

thermometer and a

hygrometer.

Measure corrosive gas.

0 to 55

When the sequencer is

used in the board, the

ambient temperature in the

board becomes the

ambient temperature.

Ambient humidity 5 to 95 %RH

Atmosphere

Corrosive gas must not be

present.

2 Power voltage

Measure a voltage across

the terminals of 100/

200VAC.

85 to 132VAC

Change the power supply.

170 to 264VAC

3

Installation

Looseness, rattling

Move the module to check

for looseness and rattling.

The module must be

installed fixedly.

Retighten the screws.

If the CPU, or power

supply module is loose, fix

it with screws.

Adhesion of dirt and

foreign matter

Check visually.

Dirt and foreign matter must

not be present.

Remove and clean.

4

Connection

Looseness of terminal

screws

Try to further tighten screws

with a screwdriver.

Screws must not be loose.

Retighten the terminal

screws.

Proximity of solderless

terminals to each other

Check visually.

Solderless terminals must

be positioned at proper

intervals.

Correct.

Looseness of

connectors

Check visually.

Connectors must not be

loose.

Retighten the connector

fixing screws.

5Battery

Check "BAT." LED on the

front face of the CPU

module.

The LED must be Off.

If the LED is On, replace

the battery.

Check the period after the

purchase of the battery.

The period must be five

years or less.

If the battery is used for

more than 5 years, replace

the battery.

Check in the monitoring

mode of GX Developer that

SM51 or SM52 is turned

OFF.

SM51 or SM52 must be

OFF.

If SM51 or SM52 is ON,

replace the battery.

6

Number of writes to

standard ROM

Check the values of SD232

and SD233 in the monitoring

mode of GX Developer.

The number of writes to the

standard ROM must be

100,000 times or less.

If the number of writes to

the standard ROM

exceeds 100,000 times,

replace the CPU module.

7 Clock

Check the current time at

the clock setting of GX

Developer.

There is no time lag

between the time checked

at the time setting of GX

Developer and the actual

time.

Change the time at the

time setting of GX

Developer.

Loading...

Loading...