moog

MSD Servo Drive Compact Operation Manual

15

[ Installation ]

to the glossaryto the table of contents

Id no.: CA97555-001, Rev. 3.0 - Date: 0 6/2012

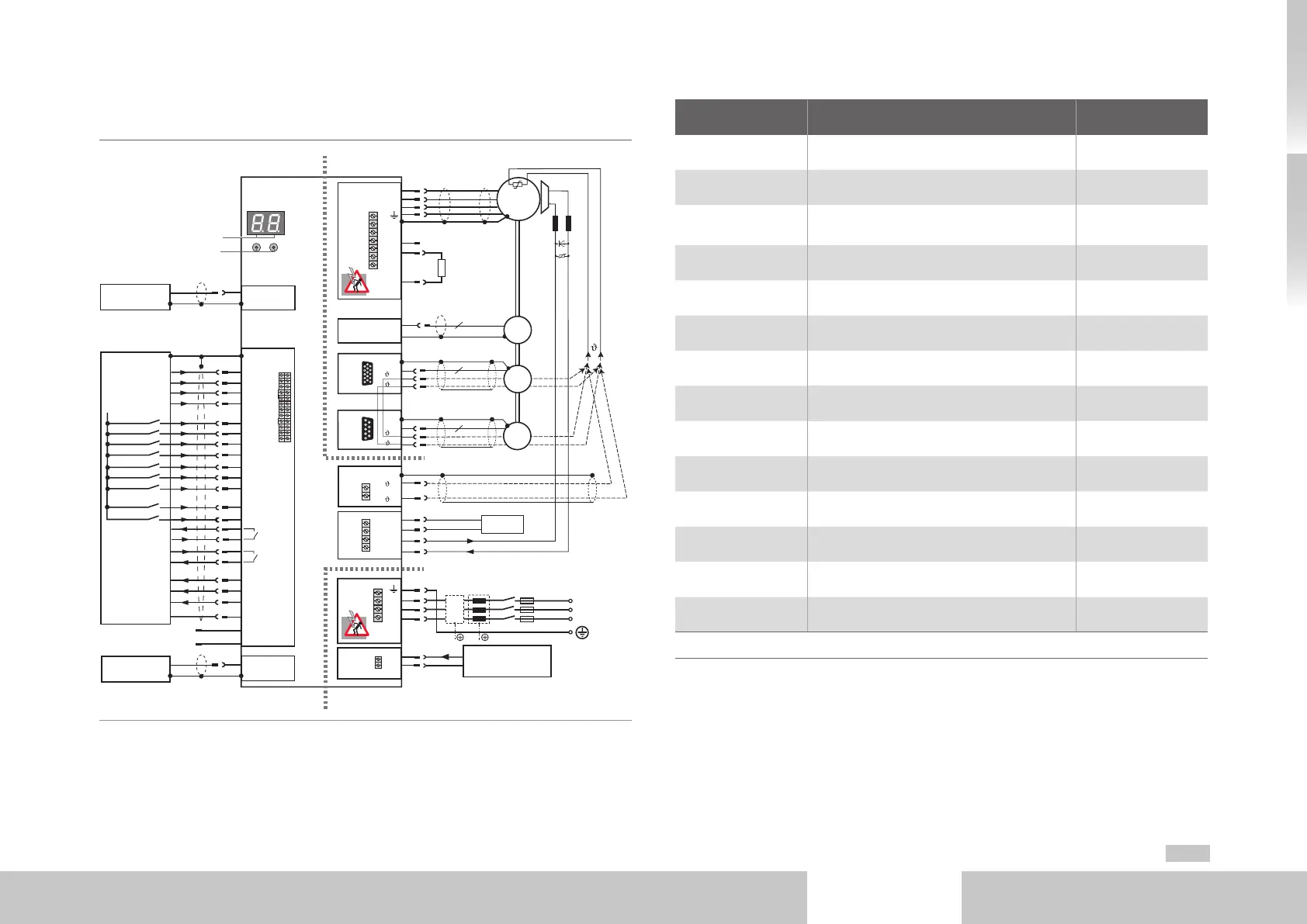

3.3 Connection diagram

Ethernet

ISD00

ISD01

ISD02

OSD02

Relay

ENPO (STO)

Motor

3

Option 2

Control

Service

interface

ISDSH (STO)

ISA00+

ISA00-

ISA01+

ISA01-

Analog setpoint 1

Analog setpoint 2

+24 V DC against

I/O-GND

+24 V (U

H

)

3

4

5

6

10

15

16

17

9

23

24

22

RSH

Diagnosis

STO

12

11

1

2,14

13

I/O-GND

Relay

Digital2

RB

L+

L-

Braking

resistor

U

V

W

6

n

n

ISD03

ISD04

ISD05

18

19

20

ISD0621

OSD01

8

Digital1

OSD00

7

Digital0

GND

GND

V+

OSD03

2

3

4

1

5

9

10

9

DC link

OSD04

54321

10 9876

15 14 13 12 11

DGND

DGND

43 21

9876

~

1+

1-

1+

1-

+

-

(-)(+)

D1, D2

T1, T2

L1

K1

L2

L3

FN

L1

L2

L3

3-phase system

X3

X2

X9

X4

X8

X7

X6

X5

X13

X1

Front

Option 1

+24 V DC supply for

control electronics (U

V

)

Communication

Fieldbuses

Brake (+)

+24 V DC supply

for brake

Brake (-)

Resolver

-

+

Encoder

+

–

TOP

BOTTOM

Fig. 3.2 Connection diagram

Number Designation Details

D1, D2 7-segment display page39

T1, T2 Button page39

X1

Connection for motor, braking resistor and

measurement of DC link voltage

page30

X2 Connection control supply page21

X3 Connection AC power supply page21

X4 Terminals page24

X5 Connection motor temperature monitoring

1)

page30

X6 Connection resolver

1)

page28

X7 Connection high-resolution encoder

1)

page29

Option 1 Communication page26

PE Connection PE conductor page19

X8 (Option 2) Technology page26

X9 Ethernet interface page26

X13 Connection motor brake

page30

1) NOTE: The temperature sensor of the motor winding can be optionally connected via the encoder cables (X6 or X7) or to

terminal X5.

Table 3.2 Key to connection diagram

Loading...

Loading...