moog

MSD Servo Drive Compact Operation Manual

23

[ Installation ]

to the glossaryto the table of contents

Id no.: CA97555-001, Rev. 3.0 - Date: 0 6/2012

DANGER FROM ELECTRICAL TENSION! Danger to life! Never wire or

disconnect electrical connections while these are live. Always disconnect the

power before working on the device. Dangerously high voltages of ≥50V

may still be present 10 minutes after the power is cut (capacitor charging). So

always check that the power has been cut.

ATTENTION! If local regulations require the installation of a residual current

operated protective device, the following applies: In case of a fault the drive

is able to generate d.c. leak currents without zero crossing. Drives therefore

must only be operated with (RCDs)

1)

type B for a.c. fault currents, pulsating

or smooth d.c. fault currents, which are suitable for servo drive operation, see

IEC60755. RCMs

2)

can additionally be used for monitoring purposes.

1) Residual current protective device

2) Residual current monitor

Note the following points:

• Switching the mains power:

− In case of too frequent switching the unit protects itself by high-resistance

isolation from the system. After a rest phase of a few minutes the device is

ready to start once again.

• TN and TT network: Operation is permitted if:

− in the case of single-phase devices for 1 x 230 V AC the supply system

conforms to the maximum overvoltage category III as per EN61800-5-1.

− in the case of three-phase devices with external conductor voltages

3x230VAC, 3x400VAC, 3x460VAC and 3x480VAC

1. the neutral point of the the supply system is grounded and

2. the supply system conforms to the maximum overvoltage category III

as per EN61800-5-1 at a system voltage (external conductor → neutral

point) of maximum 277V.

• IT network: not permitted!

− In case of an ground fault the electrical stress is approx. twice as high.

Clearances and creepages to EN61800-5-1 are no longer maintained.

!

• Connection of the servo drives by way of a mains choke is mandatory:

− where the drive is used in applications with disturbance variables

corresponding to environment class 3, as per EN 61000-2-4 and above (hostile

industrial environment)

− in the case of single-phase mains supply

− for compliance with EN61800-3 or IEC61800-3

• For further information on permissible current loads, technical data and ambient

conditions please refer to the appendix.

NOTE: Please be aware that the MSDServoDriveCompact is not rated

for environment class 3. Further measures are essential in order for that

environment class to be attained! For further information please consult your

project engineer.

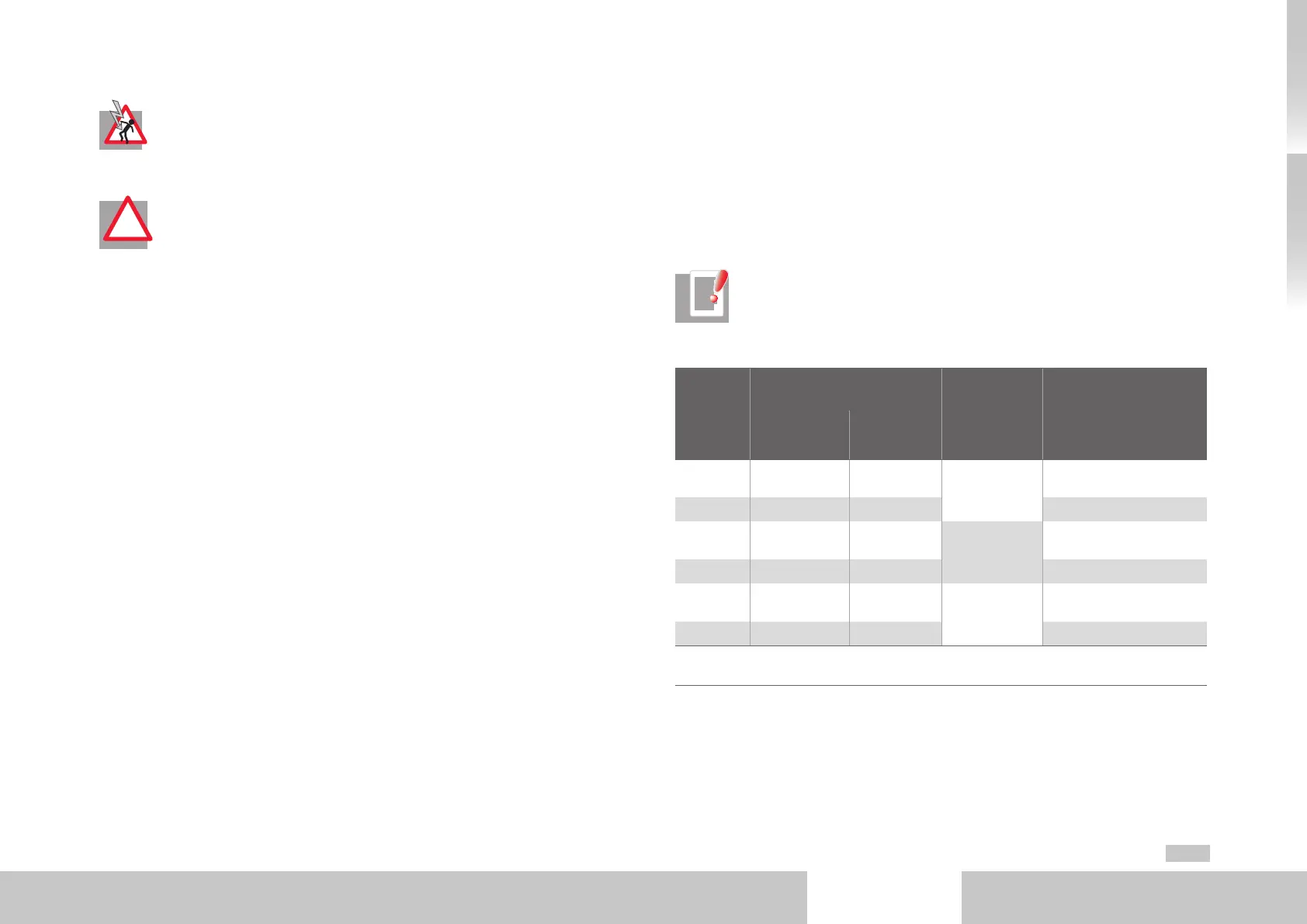

Drive

Device connected load

1)

[kVA]

Maximum

cable cross-

section [mm²]

Specified mains fuse,

duty class [A]

with mains

choke (4% u

K

)

without

mains choke

G394-030 1.3 1.6

2.5

1xmaximum 16 (1-phase)

3xmaximum 16 (3-phase)

G394-020 1.5 1.9 3xmaximum 6

G394-059 2.6 3.2

2.5

1xmaximum 16 (1-phase)

3xmaximum 16 (3-phase)

G394-035 2.7 3.3 3xmaximum 10

G394-080 3.5 4.3

4

1xmaximum 20 (1-phase)

3xmaximum 20 (3-phase)

G394-065 5.0 6.1 3xmaximum 16

1) At 3x230VAC or 3x400VAC mains voltage

2) The minimum cross-section of the mains power cable depends on the local regulations and conditions, as well as on the

rated current of the drive.

Table 3.4 Connected load and mains fuse

Loading...

Loading...