INTRODUCTION

SpotWelding Manual for Medar 1-6

MOTO

MAN

1.3.5 Water Cooling System

The water cooling system circulates water through both the spot weld controller

and the weld gun. It is important that the water temperature not exceed 86° F, as

inadequate cooling could damage the servo weld gun and transformer.

The Medar board supports thermal overload sensors from the transformer and

Medar SCR. External flow sensors may be integrated with the XRC as an interlock

for welding.

1.3.6 Tip Dresser (Optional)

The optional tip dresser is used to remove weld flash, oil, grease, or any other

deposit from the weld tip that may affect the gun’s ability to function properly.

The tip dresser also grinds the contact tip back to its original shape. The servo gun

can vary pressure during tip dress for cut and polish.

1.3.7 Work Cell

In addition to the items above, a complete system typically includes certain work

cell components. These components are not specifically part of the spot welding

package, but are related items that are supplied separately. Some of these items

include light curtains, interlocks, arc screens, fencing, and positioners. The

number and type of components required depend on the specific application.

1.4 Equipment and Component Specifications

Specifications for the typical spot welding system and its components are listed in

Table 1-1. Additional information is provided in the various vendor manuals

supplied with the system.

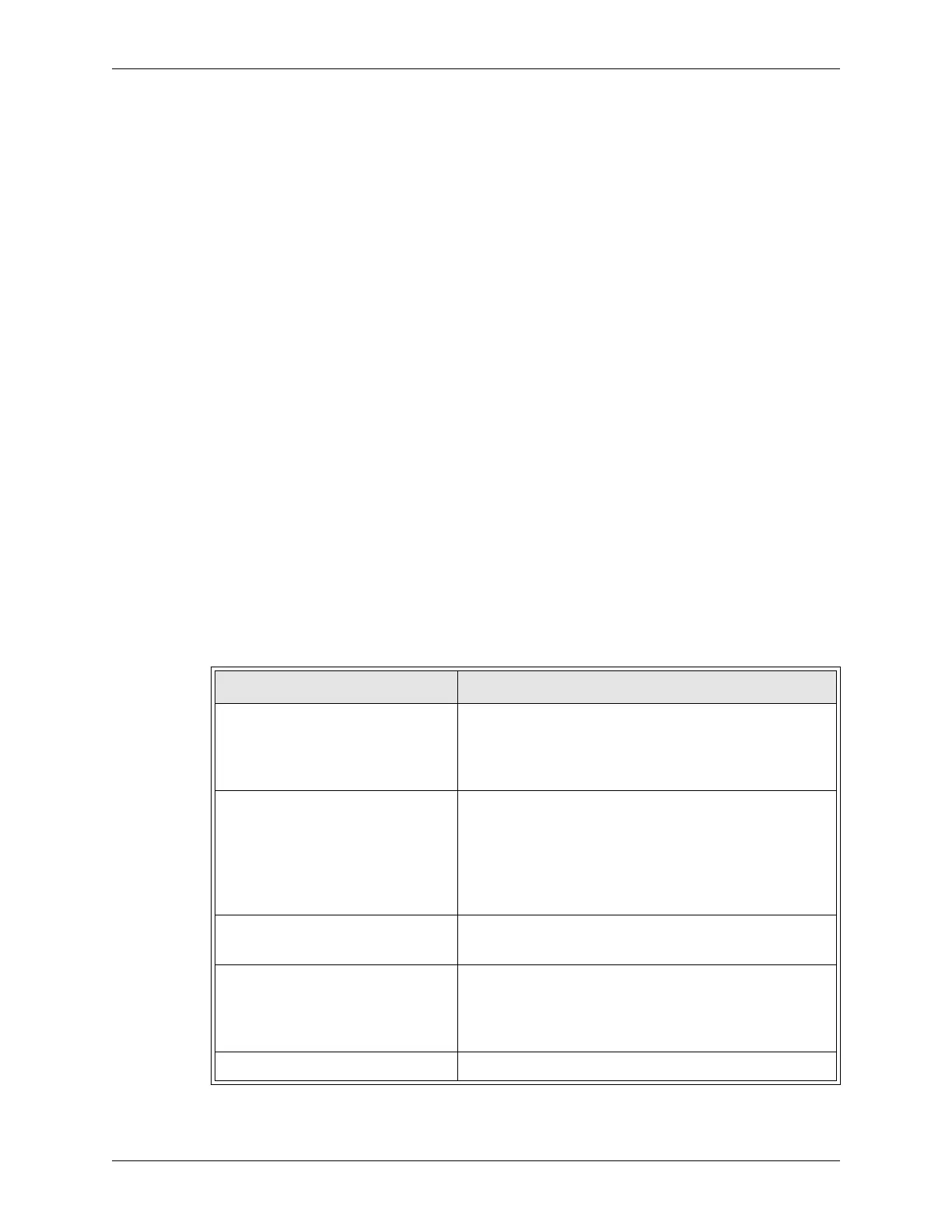

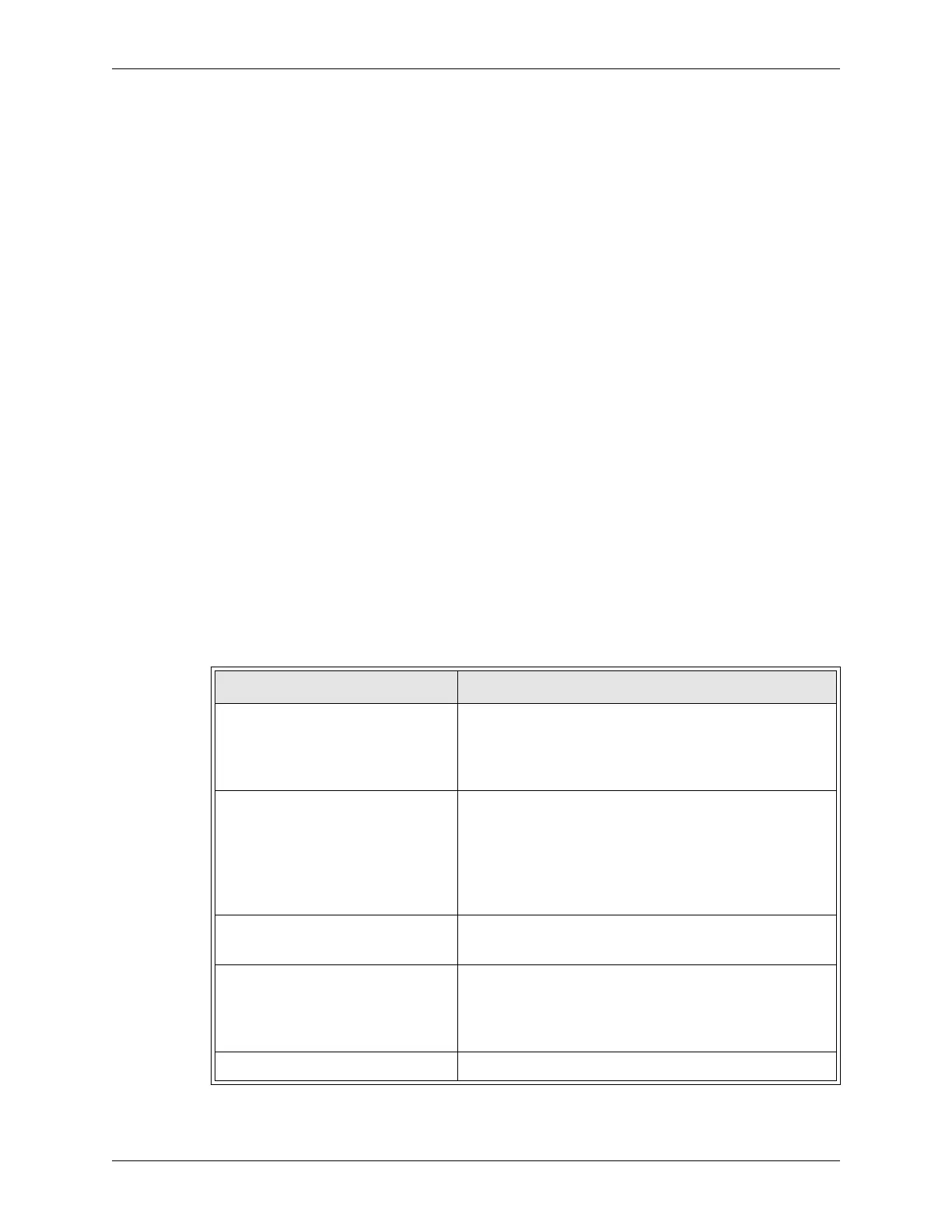

Table 1-1 Equipment and Component Specifications

Characteristic Specification

Power Requirements

Electrical service (robot)

Electrical service (welding)

Refer to manipulator manual

Refer to Integrated Spot Welding Programming Manual

for MedWeld 3006 (#T99204-01)

Operating Environment

Temperature range

Humidity

Vibration

Other

0 - 40 ˚C

20 - 80% (non-condensing)

Less than 0.5 G

Free from corrosive gases or liquids, explosive gases, and

excessive electrical noise

MedWeld 3006 Weld Control Refer to the Integrated Spot Welder Programming Manual

for MedWeld 3006 (#T99204-01)

Spot Weld Gun Servo motor is controlled by the XRC. Refer to the spot

gun manufacturer’s specifications. Note that when used

with the ES165 robot, the largest spot gun motor that can

be used is a 2 kW.

Water Circulator Varies. See vendor manuals for specific information.

Loading...

Loading...