TROUBLESHOOTING

Spot Welding Manual for Medar 5-6 MOTOMAN

• Use a rubber mallet to align holder and tips, instead of a metallic tool.

• Avoid leaving electrodes unused in tapered holder seats for long periods of

time.

• Use a tip dresser on a regular basis to maintain correct electrode contour.

Never dress an electrode using a coarse file.

• Clean the tip taper and holder taper on a regular basis, removing foreign

materials.

• To simplify tip removal and avoid tip damage, coat the tip with a thin film of

cup grease before placing it in the holder. Use ejector-type holders to avoid

damaging tip walls. Never use pipe wrenches or similar tools when removing

electrodes.

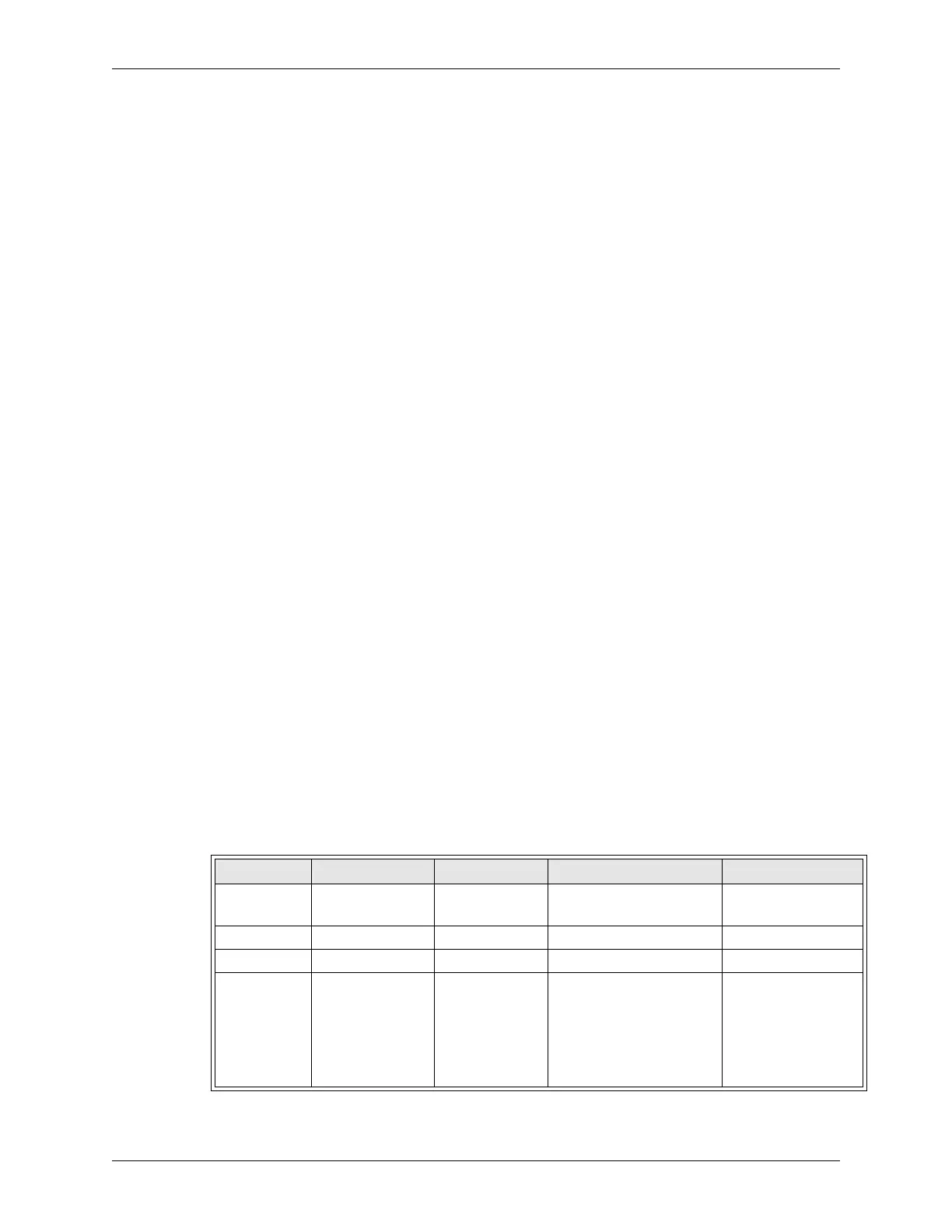

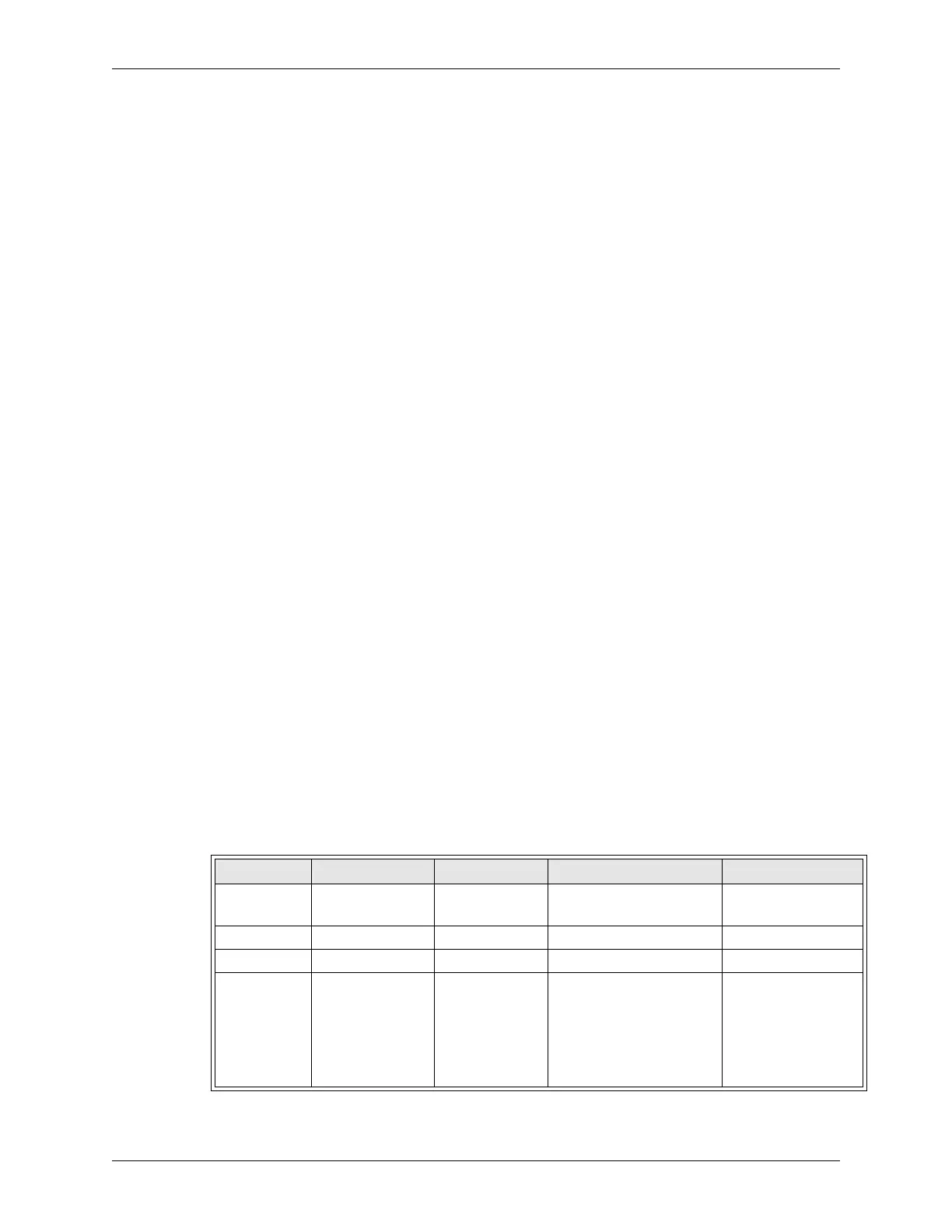

5.5 Troubleshooting Dual Port RAM I/O

If a communication problem occurs in the XRC-to-Medar spot welding interface,

use the dual port RAM memory I/O information in Tables 5-4 and 5-5 to

troubleshoot the problem. These tables list the concurrent I/O addresses used to

check the status of the dual port RAM inputs and outputs. The dual port RAM

interface consists of M-registers, which are copied to and from the auxiliary

addresses shown in the tables.

Execute the SPOT command and verify the following I/O definitions:

1. Weld sequence numbers 7100 - 7107 should pulse in a non-zero bit pattern.

2. Critical outputs should be defined as follows:

• 7120 = 0

• 7121 = 0

• 7123 = 1

• 7124 = 1

• 7157 = 1 (MFDC only)

3. Critcal inputs should be defined as follows:

• 7221 = 1

• 7222 = 0

• 7257 = 1 (MFDC only)

Table 5-4 XRC Outputs to Medar Board

Byte M-Resister AUX Address Description I/O Definition

Host Count M000 High Byte 7110 - 7117 Counter to verify commu-

nication.

Increments 0 to

65535

Sequence # M000 Low Byte 7100 - 7107 Weld Sequence Number 1 to 255

Stepper Reset M001 High Byte 7130 Stepper Reset 1 = Active

Control 1 M001 Low Byte 7120

7121

7122

7123

7124

7125 - 7127

Control Stop

Isolation Contactor Status

Fault Reset

No Weld

Weld Initiate

Reserved

0 = Active

0 = Closed

1 = Active

0 = No Weld

1 = Initiate

-

Loading...

Loading...