SETUP AND OPERATION

MOTOMAN 4-5 Spot Welding Manual for Medar

Figure 4-1 Simple Weld Condition File

4.4 Enhanced Weld Schedules

To set up an enhanced weld schedule, first follow the instructions in paragraph 4-1,

step 5, and set the weld schedule type to Enhanced (1). Then, using the XRC

programming pendant, follow these instructions:

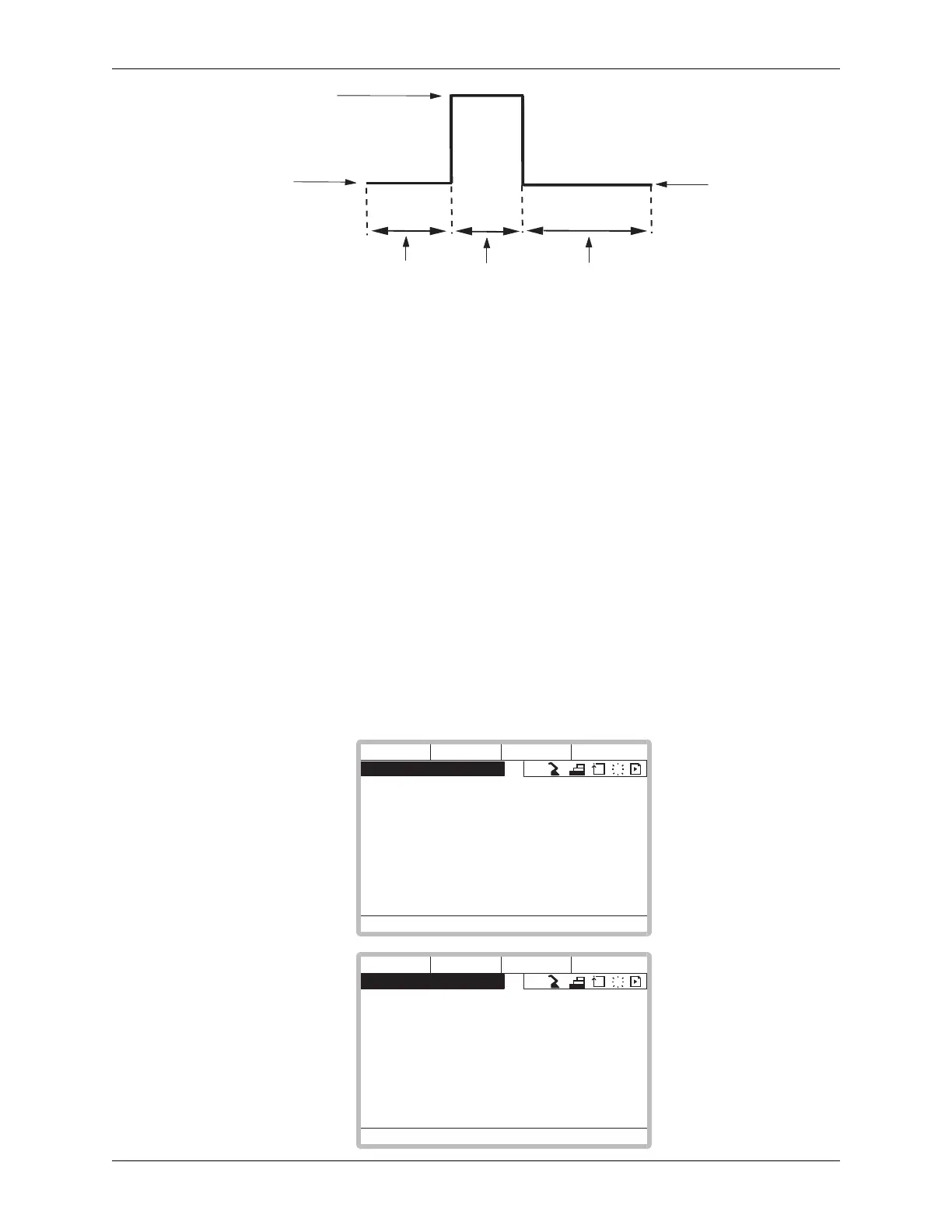

1. From the Spot Welding Function Menu, select WELDING COND. The first

enhanced weld condition file will appear. Use the CURSOR key to scroll

through the file. Figure 4-2 depicts this particular enhanced weld condition

file.

NOTE: Any of the weld segments shown in Figure 4-2 can be eliminated by entering zero in the timers.

Likewise, slopes can be eliminated by making the start and end values the same. Cool times

can be eliminated by setting them to zero.

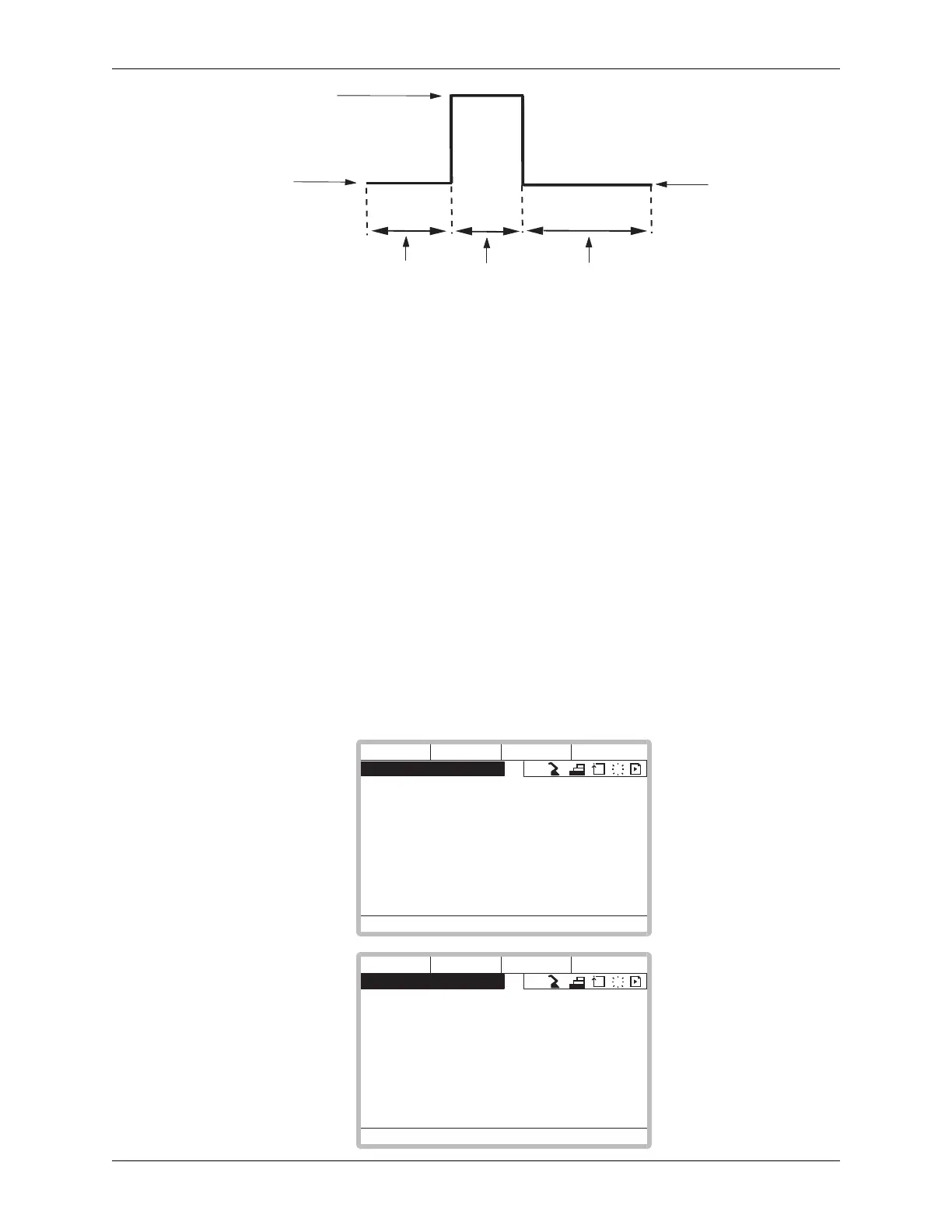

SQUEEZE

TIME

(5 cycles)

9000 AMPS

GUN CLOSED

*

GUN OPEN

WELD

TIME

(4 cycles)

HOLD

TIME

(10 cycles)

NOTE: Timers are programmed in cycles.

One cycle = 1/60 sec; 4 cycles = 4/60 sec

*

If a servo gun is used, set the squeeze time to zero. The weld schedule will not start until

the programmed pressure is achieved. The WST (0 - 2) parameter in the SV spot instruction

(see Motor Gun Function Manual) defines whether to start the weld schedule at the first or

second pressure level in the gun pressure file.

* If a pneumatic gun is used, increase the SQUEEZE TIME to enough cycles to allow the

gun to close and settle.

WELD CONDITION FILE

!

R1

S

C

L

DATA

EDIT DISPLAY UTILITY

DOWNLOAD: DONE/NOT DONE

FILE NO.

:

SQUEEZE TIME

:

WELD1 SLOPE TIME

:

WELD1 BEG SLOPE CURRENT

:

WELD1 END SLOPE CURRENT

:

WELD1 COOL TIME

:

WELD2 IMPULSE HEAT TIME

:

WELD2 IMPULSE COOL TIME

:

1

5

10

3500

5500

5

4

8

WELD CONDITION FILE

!

R1

S

C

L

DATA

EDIT DISPLAY UTILITY

WELD2 IMPULSE COUNT :

WELD2 CURRENT

:

WELD2 COOL TIME

:

WELD3 POSTHEAT TIME

:

WELD3 CURRENT

:

HOLD TIME

:

3

9000

0

8

4000

10

Loading...

Loading...