THEORY OF OPERATION

MOTOMAN 3-9 Spot Welding Manual for Medar

The use of steppers can compensate for current density losses. By boosting the

current as caps “mushroom,” current density is maintained. In addition to the use

of steppers, tip dressing equipment can be used to machine electrodes. Resurfacing

makes them like new again.

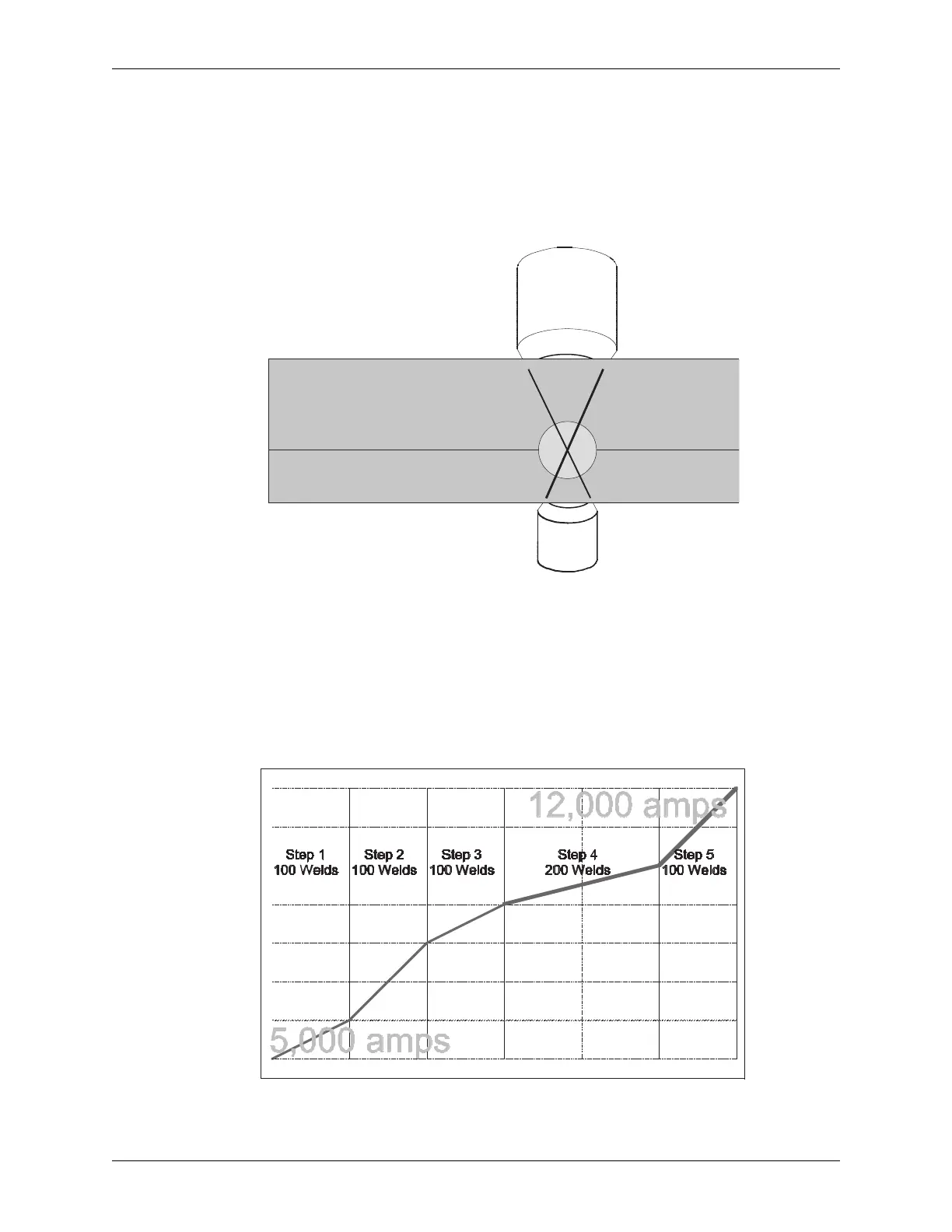

Different sized caps cause the heat to be focused at a different point in the welding

process. This can be advantageous when welding metal stackups with different

part thicknesses. See Figure 3-9.

Figure 3-9 Welding Different Part Thicknesses

3.6.1 Steppers

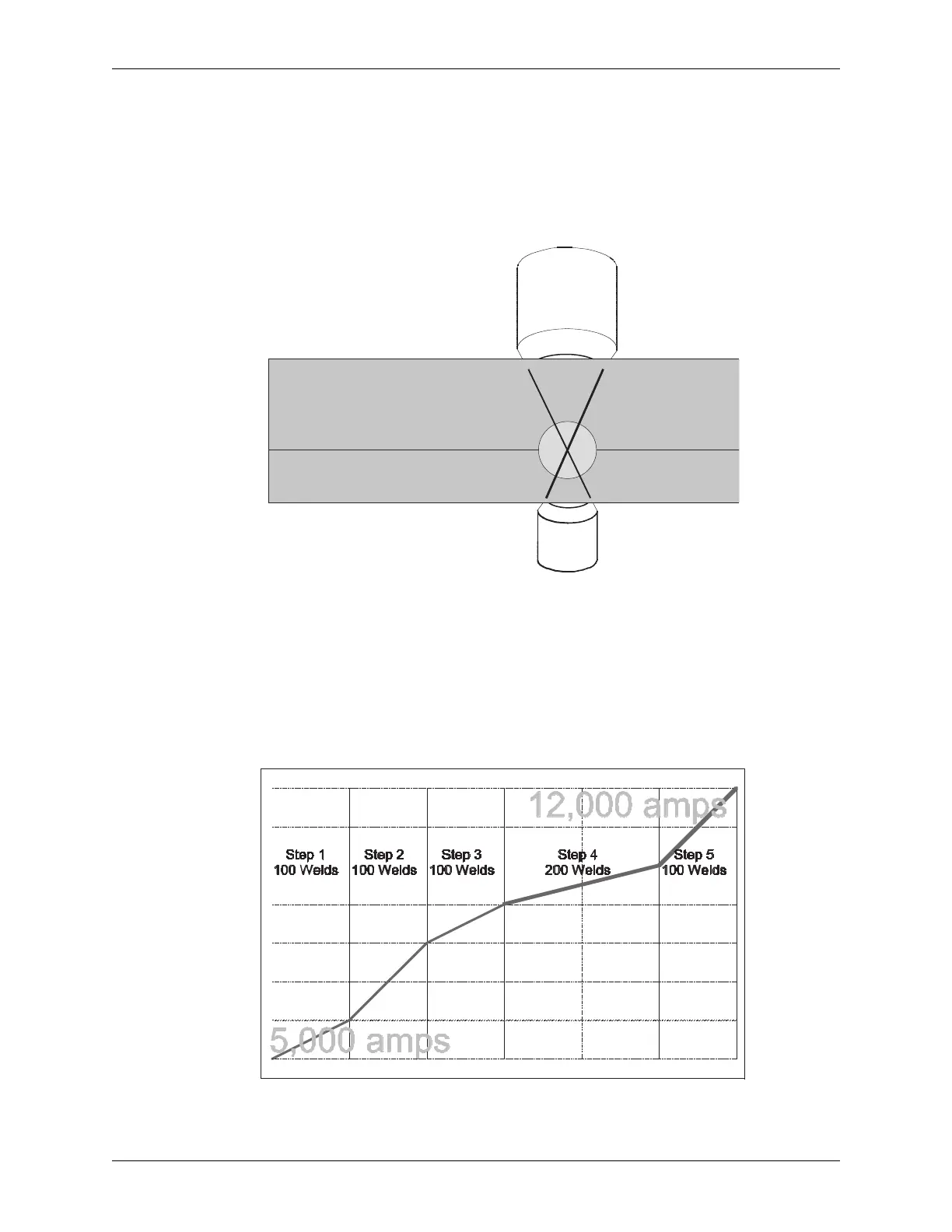

Steppers are designed to increase current (deliver more heat), time (deliver longer

heat), or pressure (deliver lower tip-to-part resistance). Steppers are typically

programmed as a series of steps. During each stepper step, current will gradually

increase from the first weld to the last weld in that step. Figure 3-10 illustrates a

stepper program with five steps.

Figure 3-10 Stepper Program

Loading...

Loading...