THEORY OF OPERATION

Spot Welding Manual for Medar 3-2 MOTOMAN

3.2 The Weld Cycle

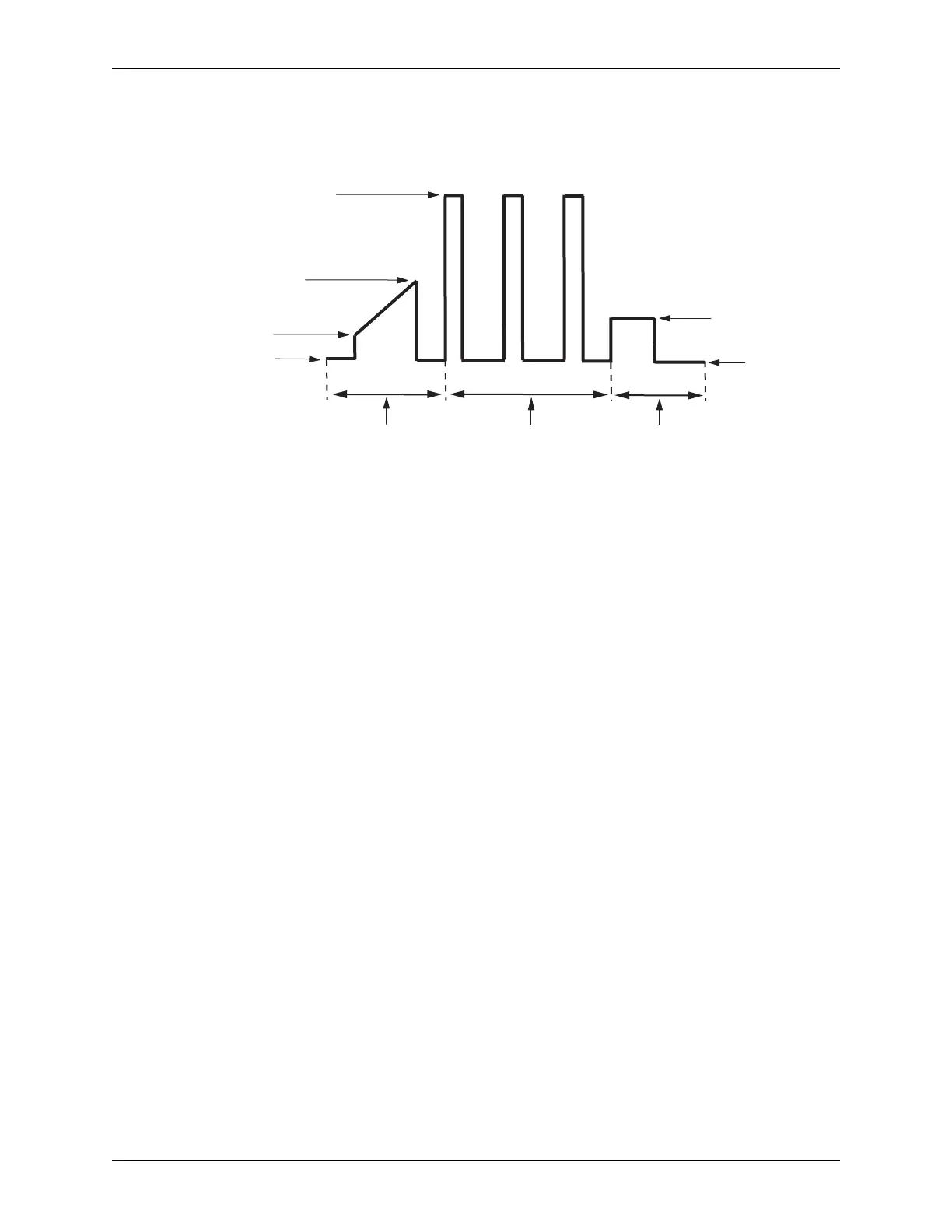

A typical resistance weld is broken down into several distinct periods, as shown in

Figure 3-1.

Figure 3-1 The Weld Cycle

The Squeeze Time occurs when the weld heads (electrodes) come together and

build up to a specified amount of force before the current is fired.

The Weld Time is the time it takes the current to actually pass through the

workpieces. During the Weld Time, the metals are heated enough to melt and fuse

together to form what is called a weld nugget.

During the Hold Time, electrode force is still applied, even after the weld current

has ceased. During this period, the weld nugget cools and the metals are forged

under the force of the electrodes. The continuing electrode force helps keep the

weld intact until it solidifies, cools, and the weld nugget reaches its maximum

strength.

3.3 Critical Factors in Resistance Welding

Understanding the resistance weld process requires an understanding of the main

factors involved and how they work together. This section will review current,

voltage, resistance, and power, as well as the various functions of the electrodes

and how they affect surface contact and current density.

3.3.1 Current

Current, usually measured in Kilo-Amperes (one Kilo-Amp is equal to 1,000

Amps), is one of the most important factors in spot welding. A resistance weld

cannot be made unless there is sufficient weld current.

The typical amount of current needed to weld low-carbon steel, for example, is

about 10,000 Amps (10 KA) at about 5 Volts. To put this in perspective, a normal

household or office outlet provides a maximum of 15-20 Amps (0.015-0.020 KA)

at 120 Volts, while a power circuit in a factory may only be capable of providing

200 Amps (0.200 KA) at 500 Volts to a welder. The factory's 200 Amps is then

converted to the 10,000 Amps needed to weld by means of a welding transformer.

A transformer consists of two coils of wire, called the primary and the secondary,

wound around an iron core. See Figure 3-2. Power is transferred from primary to

secondary via the magnetic properties of the iron. The factor by which the current

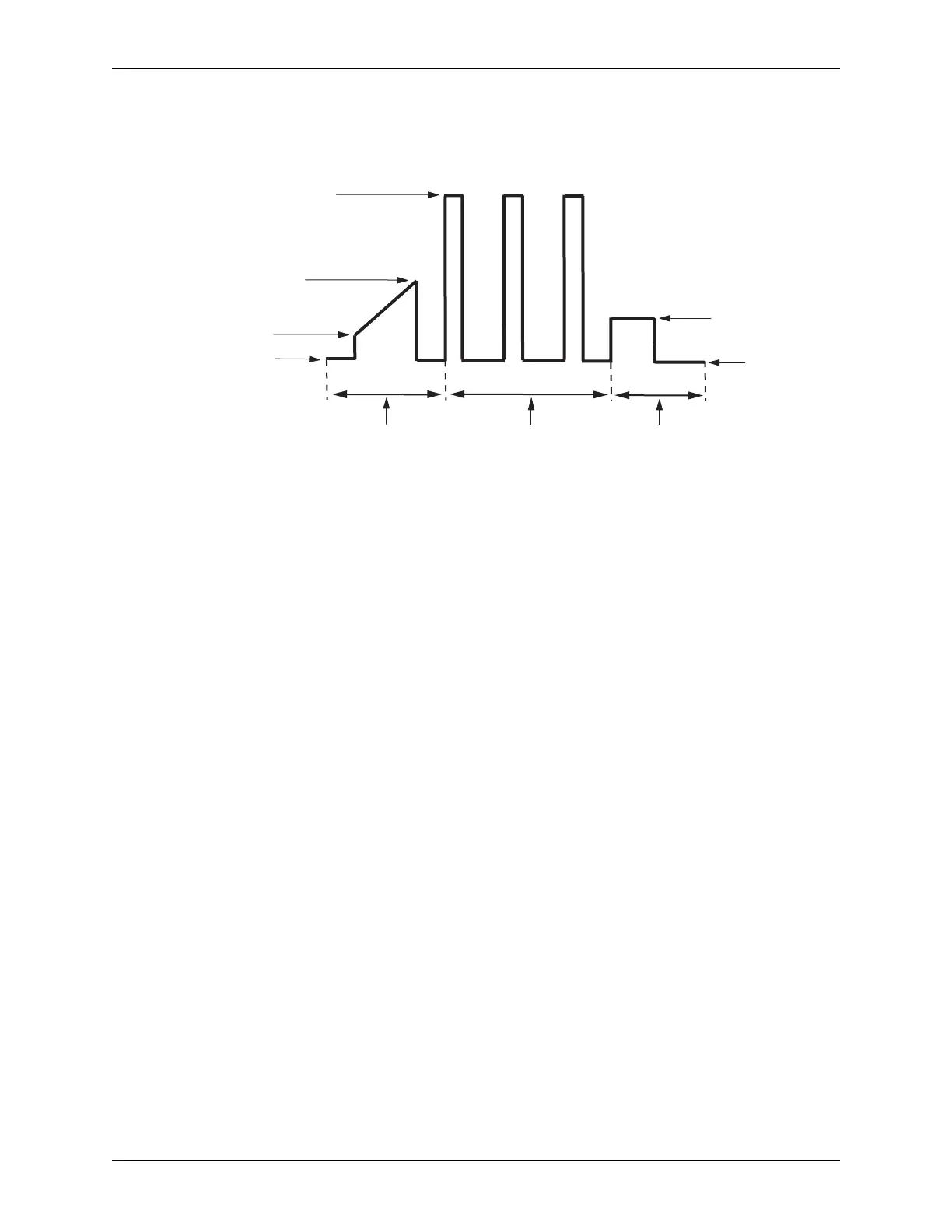

WELD 1

PREHEAT Segment

(20 cycles total)

3500 AMPS

GUN CLOSED

GUN OPEN

5500 AMPS

9000 AMPS

4000 AMPS

5

10

5

4 4

4

8 8 8

8

10

WELD 2

WELD Segment

(36 cycles total)

WELD 3

POSTHEAT Segment

(18 cycles total)

Loading...

Loading...