THEORY OF OPERATION

Spot Welding Manual for Medar 3-4 MOTOMAN

3.3.4 Secondary Resistance

Secondary resistance is the resistance of the entire welding secondary circuitry.

Secondary resistance significantly impacts the amount of I (current) available. In

the following example, the turns ratio is 48:1, and the secondary resistance is 500

micro-ohms.

3.3.5 Reactance, Resistance, and Power Factor

Resistance plays a vital role in the amount of current a welding power source can

deliver. In addition, reactance ((inductance and capacitance), impedance, and

power factor all help determine the capabilities of a welding tool.

An AC current passing through a coil (such as a transformer) is impeded by a

property called inductance. As power passes through the transformer windings,

the current is “stored” in space around the coil in the form of a magnetic field,

while voltage is unimpeded. When the voltage changes direction, this field

collapses, inducing current into the coil once again. Thus, in a phase shift due to

inductance, voltage leads current. The mathematical symbol for inductance is “L.”

Pure resistance applies to both AC and DC currents, but inductance and

capacitance cause an extra type of resistance to AC called impedance. Impedance

is the result of the phase shift that occurs in inductance and capacitance. The

mathematical symbol for impedance is “Z.” If you know inductance (L),

capacitance (C), and resistance (R), you can figure out impedance (Z). The formula

is Z = square root of (L-C)

2

+ R

2

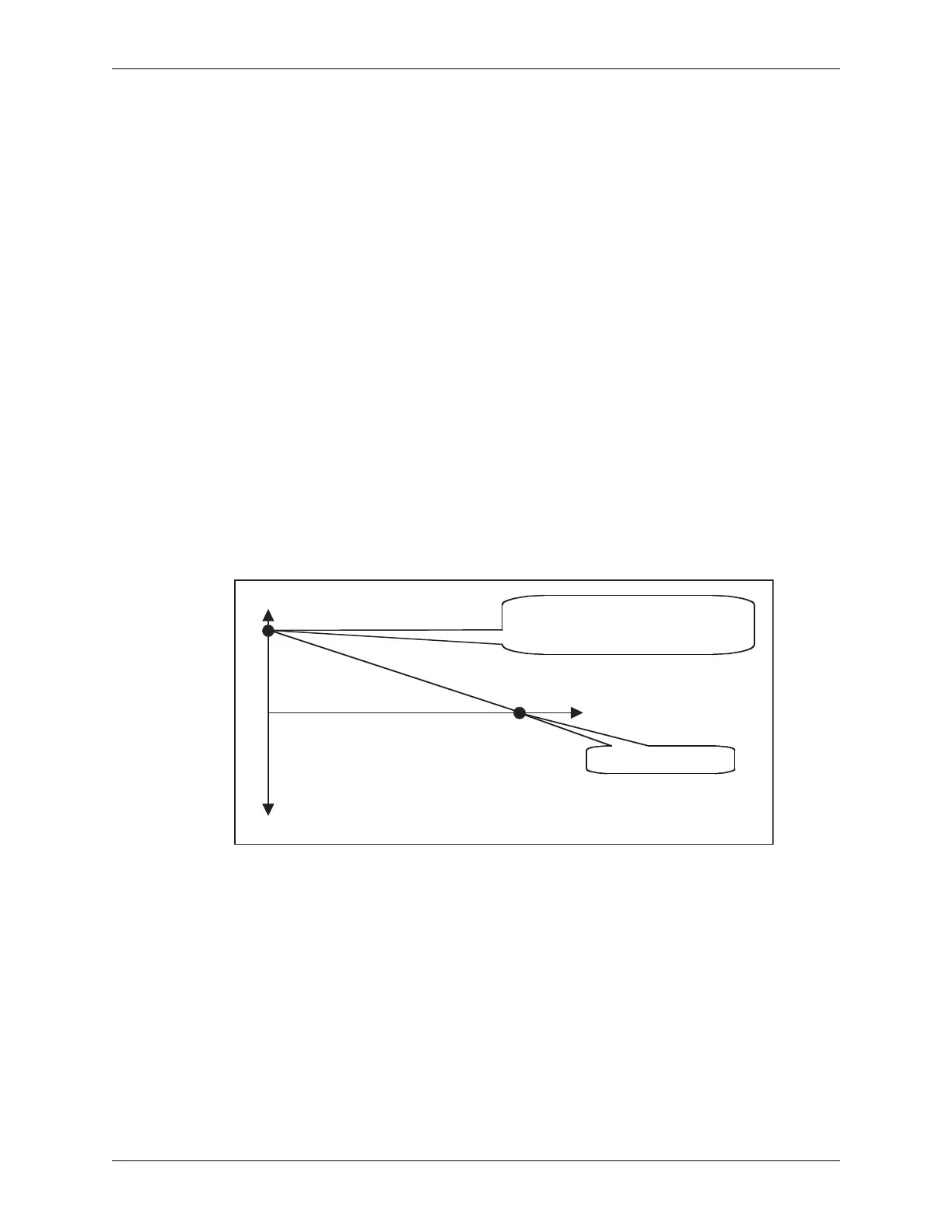

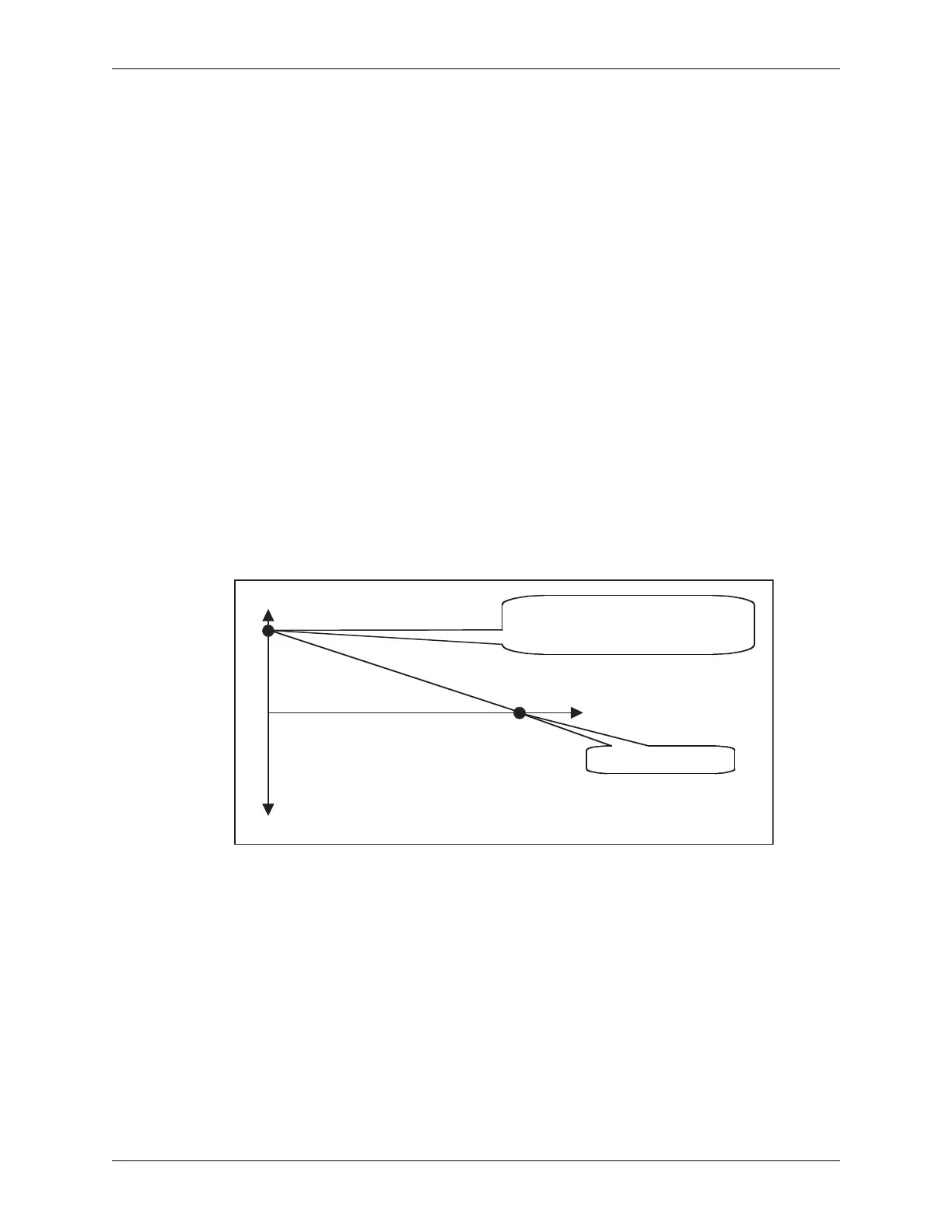

. See Figure 3-3.

Figure 3-3 Reactance, Impedance, and Power Factor

Once you know impedance, you can calculate the power factor. Power factor is the

amount of useful power used. Its value is always expressed as a decimal less than

one (e.g., 0.90 or 90%). Low power factor is inefficient. Welding with 10 kA at

65% power factor actually requires 15.4 kA. The formula is Power Factor = R÷Z.

Monitoring a weld control’s power factor over time indicates much about the

condition of the welding circuit. Over time, power factor will get higher, because

as a tool ages, its resistance increases. Because the weld control calculates power

factor and resistance for you, you can calculate impedance without knowing the

reactance of the secondary circuit. A large drop in power factor can indicate poor

connections that require maintenance.

L and C directly counteract each other.

This value represents the difference

between them.

Pure Resistance Value

L

C

Z

R

Loading...

Loading...