INTRODUCTION

SpotWelding Manual for Medar 1-2

MOTO

MAN

1.2 System Configuration

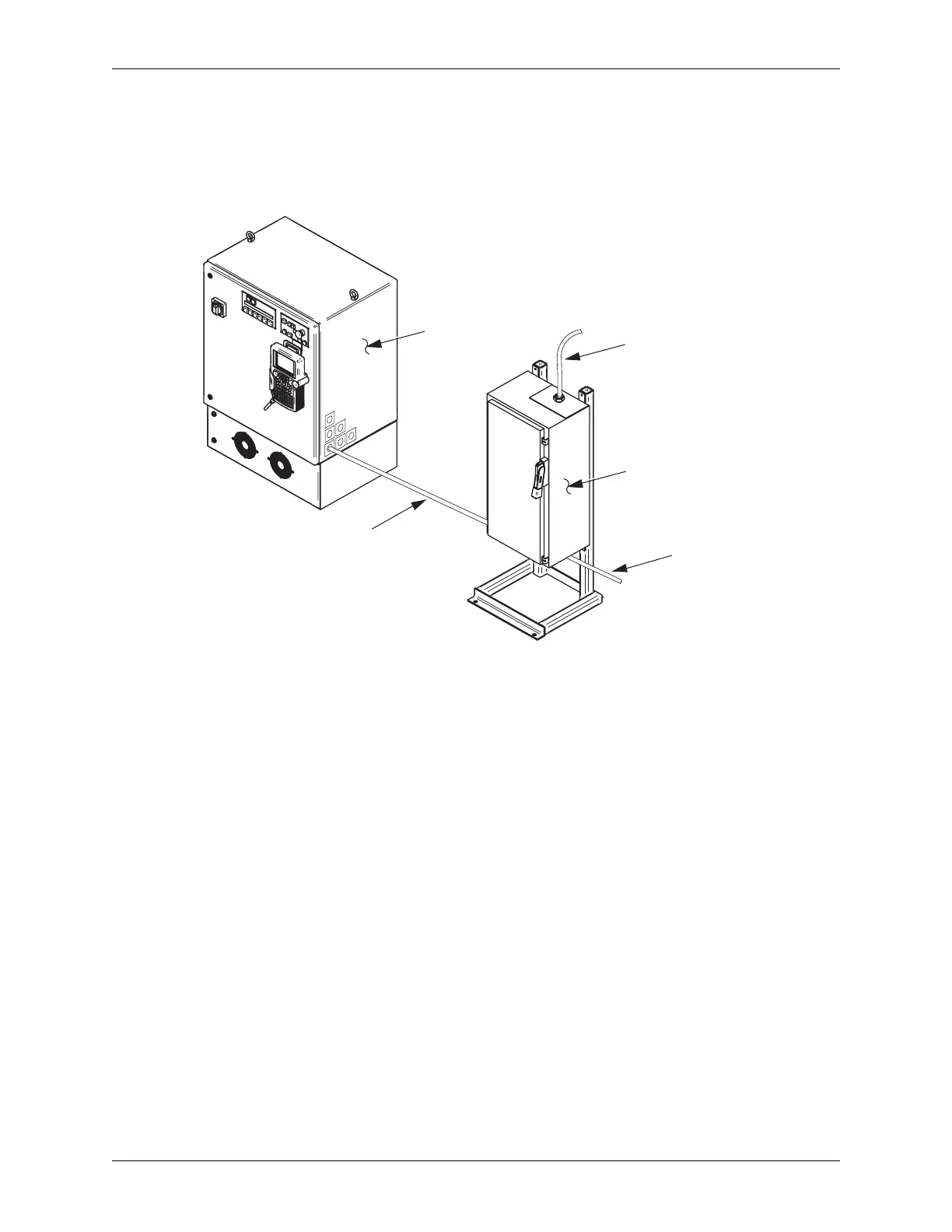

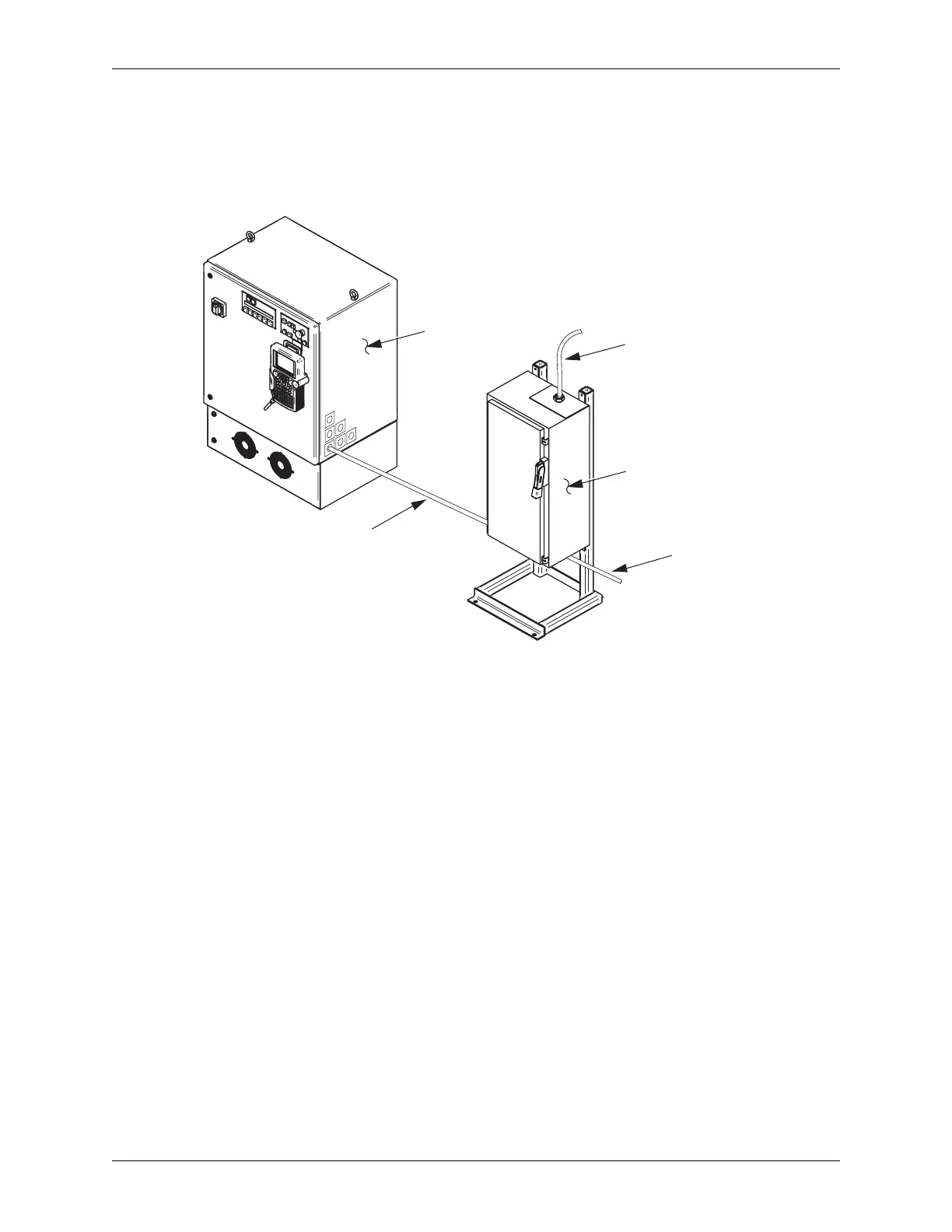

A spot welding system is an integrated package of tools and components designed

to meet specific welding requirements. A typical system includes the components

and optional equipment listed below. Figure 1-1 shows a typical system

configuration.

Figure 1-1 XRC and Medar Integrated Weld Control

• Motoman robot manipulator and XRC 2001 controller

• 3-Slot CPU rack

• Medar integrated welding board

• Welding equipment, including the following:

• Medar 3006 integrated weld control

• MedWeld cable

• Transgun (air or servo-driven)

• Water circulator/chiller

Options for the welding system include:

• Tip dresser

• Tip changer

The XRC controls the operation of the spot welding system. It coordinates the

operation of the various components of the system through execution of instruction

sequences provided in the robot program or “job” file. As the XRC steps through

the series of instructions, it directs the movement of the robot and operates the

weld control.

XRC ROBOT

CONTROLLER

MEDAR

WELD CONTROL

INCOMING POWER

(CUSTOMER–SUPPLIED)

XRC TO MEDAR

INTERFACE CABLE

OUTGOING POWE

TO TRANSGUN

Loading...

Loading...