SETUP AND OPERATION

MOTOMAN 4-7 Spot Welding Manual for Medar

3. Selecting RESET STEPPER resets to Step 1, weld count zero.

NOTE: When an automatic tip changer is used, the robot job can reset the stepper to Step 1 by pulsing

Universal Output #185. After an automatic tip dressing, the robot job can reset the stepper to

Step 2 by pulsing Universal Output #186.

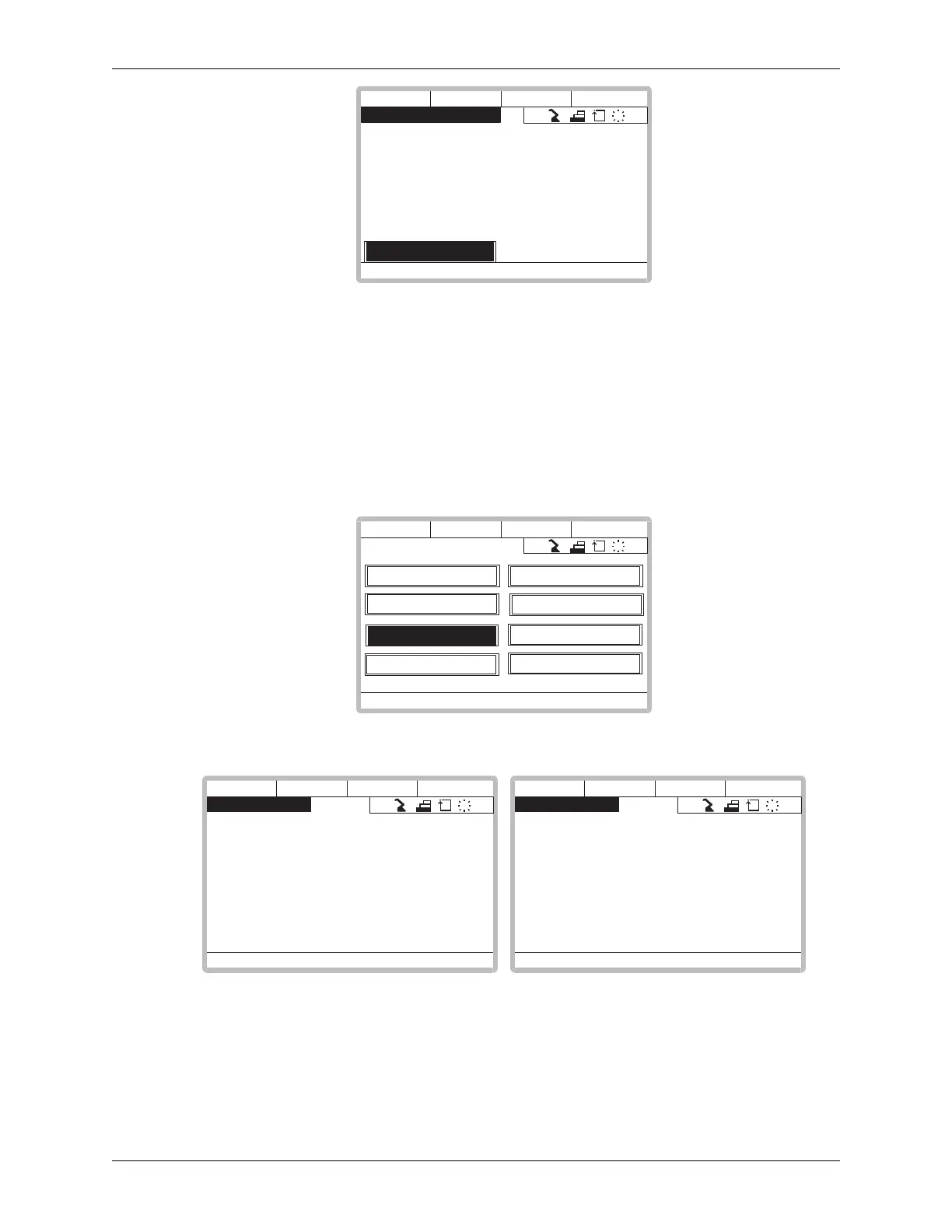

4.6 Monitoring Weld Results

This screen displays weld data. For a complete explanation of C-Factor and Power

Factor data, refer to the Manual for the Medar Integrated Weld Control, Appendix B.

1. From the Spot Welding Function Menu, select WELD MONITOR.

2. The following listing of weld results will appear (the screen on the left shows

the weld results for AC; the screen on the right shows the results for MFDC):

EDIT DISPLAY

DATA UTILITY

R1

S

C

L

STEPPER#1, GROUP#0

TOTAL WELDS :

STEP NUMBER

:

STEP COUNT

:

!

250

2

150

RESET STEPPER

STEPPER CONDITION

R1

S

C

L

I/O ALLOCATION

WELDER CONDITION

GUN CONDITION

WELD MONITOR

WELDING COND

WELD SETUP

STEPPER COND

!

WELD DIAGNOSIS

EDIT DISPLAY

DATA UTILITY

R1

S

C

L

<

PREVIOUS WELD RESULTS

>

C-FACTOR

:

AVG LINE VOLTAGE

:

AVG SEC. CURRENT

:

AVG POWER FACTOR

:

AVG %I USED

:

STEP NUMBER

:

!

140

489

9000

90

42

4

RESET FAULTS

WELD MONITOR

REVISION: 80042MI/T99204-00-05

EDIT DISPLAY

DATA UTILITY

R1

S

C

L

<

PREVIOUS WELD RESULTS

>

C-FACTOR

:

AVG DC BUS (VOLTAGE)

:

AVG SEC. CURRENT

:

AVG POWER FACTOR

:

AVG %I USED

:

STEP NUMBER

:

!

140

425

9000

90

42

4

RESET FAULTS

WELD MONITOR

REVISION: 80042MI/T96204-00-05

Loading...

Loading...