THEORY OF OPERATION

Spot Welding Manual for Medar 3-6 MOTOMAN

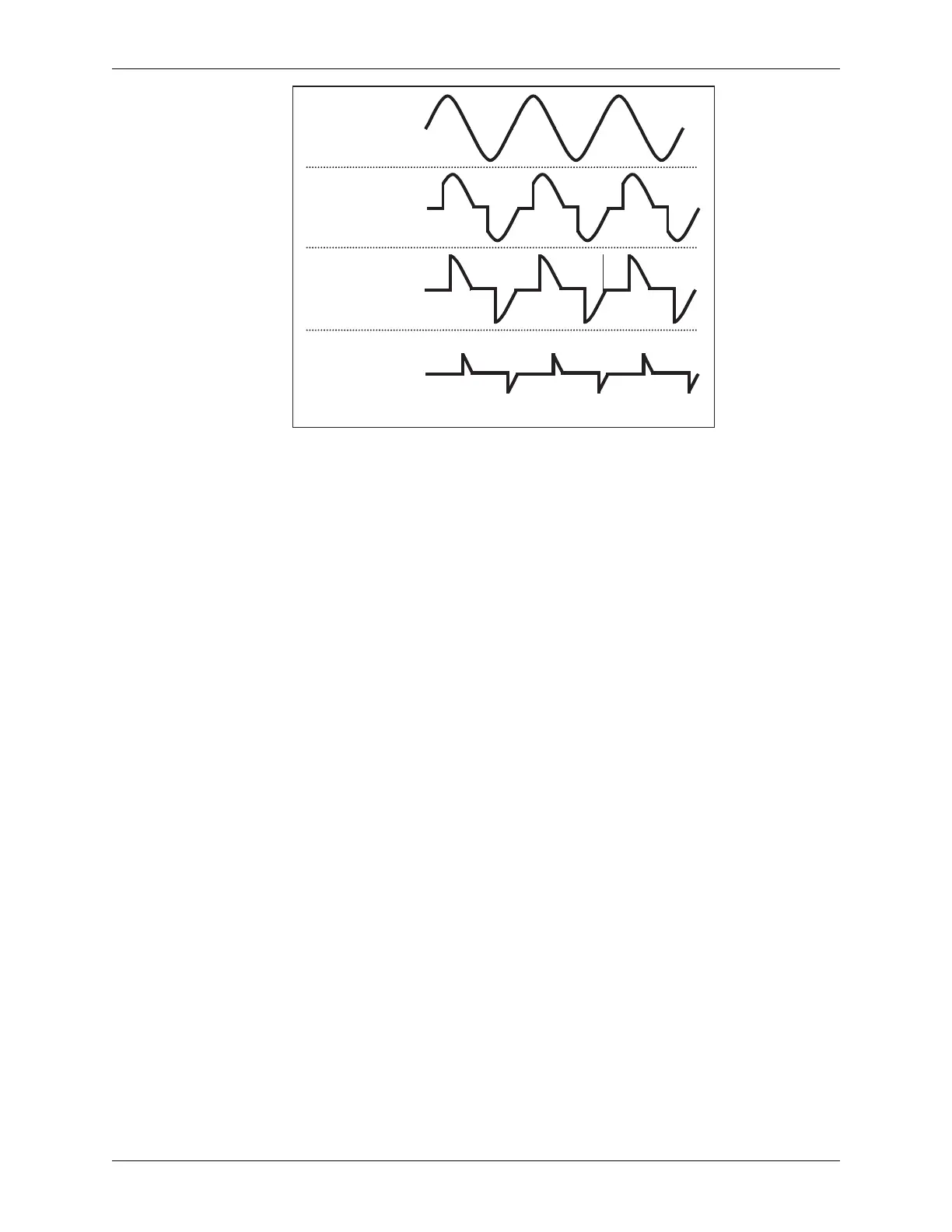

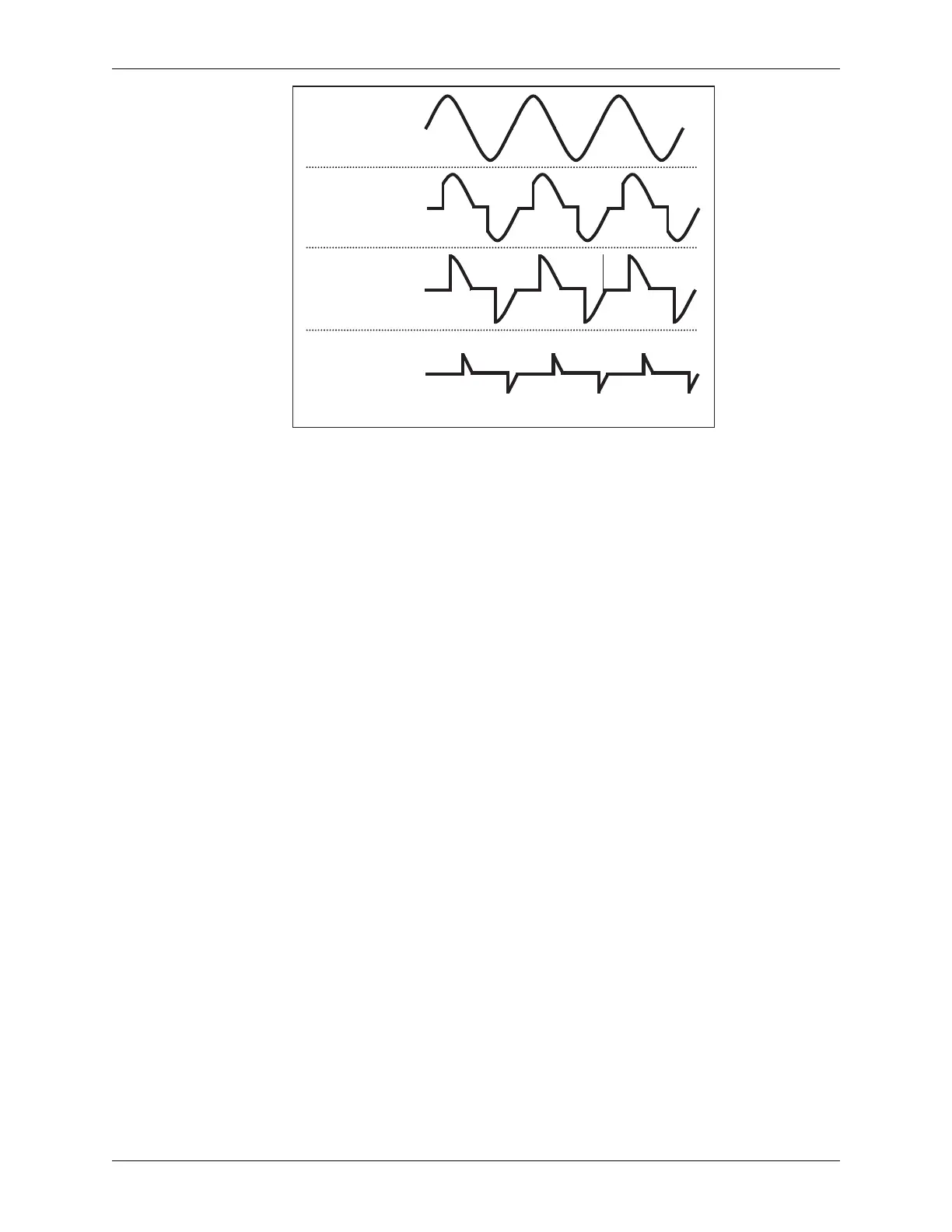

Figure 3-5 Regulating Current

AC welding uses the concept of cycles to determine duration of time. In North

America, the welding buss frequency is 60 Hz, also known as 60 cps (cycles per

second). One complete cycle is equal to 1/60 seconds.

3.5 DC Welding

DC, or MFDC (mid-frequency direct current) uses mid-frequency inverters to

convert AC line power to DC current. MFDC welding improves quality and

reduces costs as well as cycle time. MFDC welding is more energy efficient than

AC welding. Power factor is always “1.” No need to balance power factor when

using multiple guns in a plant. With AC welding, power losses occur from

magnetic flux.

MFDC welding is advantageous for welding aluminum, multiple sheets in a thick

stack, or applications where gun arms are extremely long.

3.6 Spot Welding Theory

The welding gun’s electrodes are made of copper. Because copper is quite

thermally conductive, it draws the heat out of a weld point faster than the

surrounding air, and faster than the surrounding metal of the part. The copper is

also resistant to fusing to steel parts.

The copper is water-cooled. This cooling allows the weld point to solidify after

being melted during weld time (the parts will stay welded together). Too slow or

too much cooling may cause the electrodes to stick to the part. Too little cooling

may cause welds to come apart (especially if the electrodes are used for clamping).

Too rapid cooling can cause the weld spot to crystallize, resulting in an extremely

weak weld.

Pressure increases the area of contact and minimizes resistance between each

electrode and the part surface (the most resistive part of the circuit must be where

the parts join together at the weld point). Too little pressure causes increased

resistance at the tip-to-part contact area. This will result in metal loss as expulsion.

Too much pressure can cause severe indentation at the weld point, because the

electrodes continue to press together as the metal liquefies.

0° firing

45° firing

90° firing

135° firing

Loading...

Loading...