Section 2, Installation and Setup

Chemgard Infrared Gas Monitor

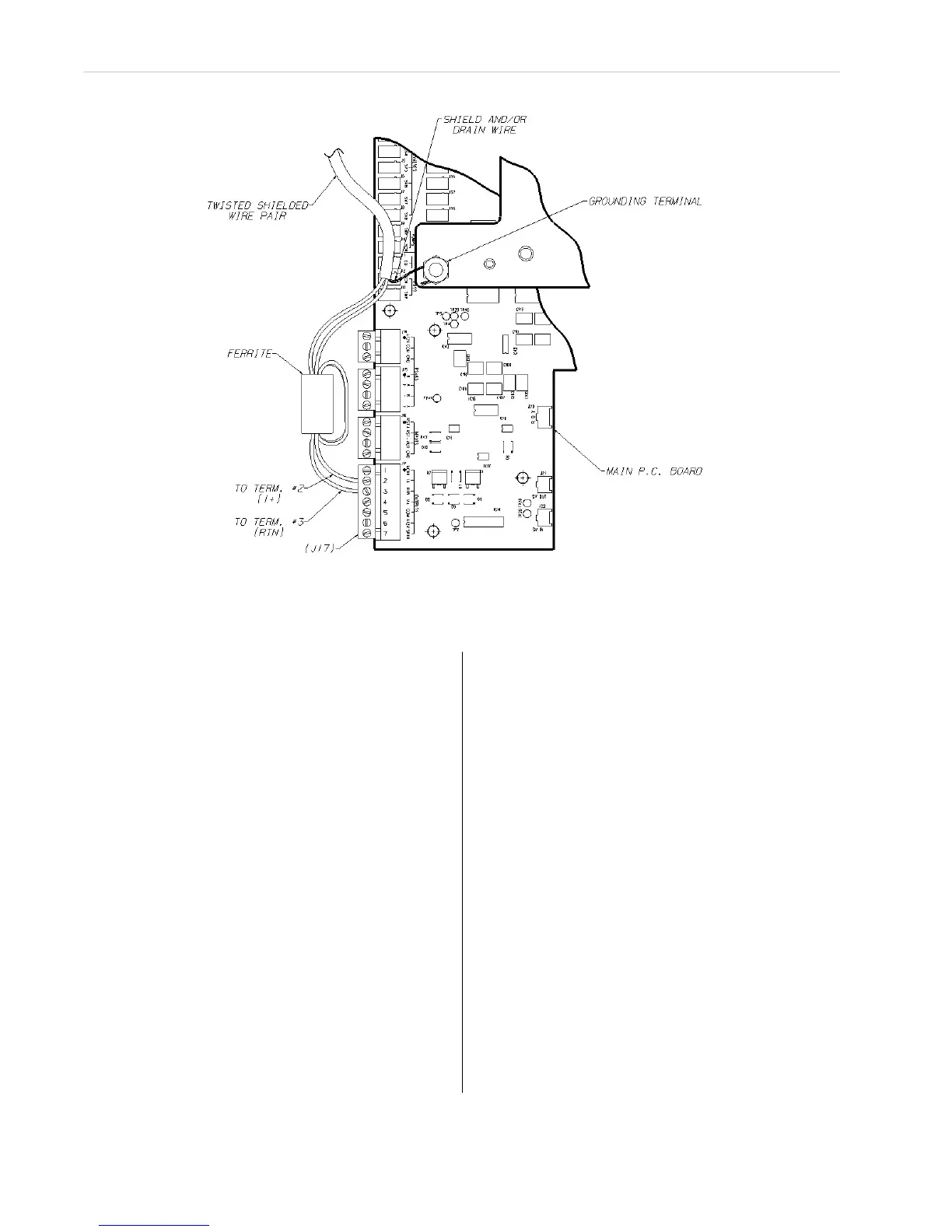

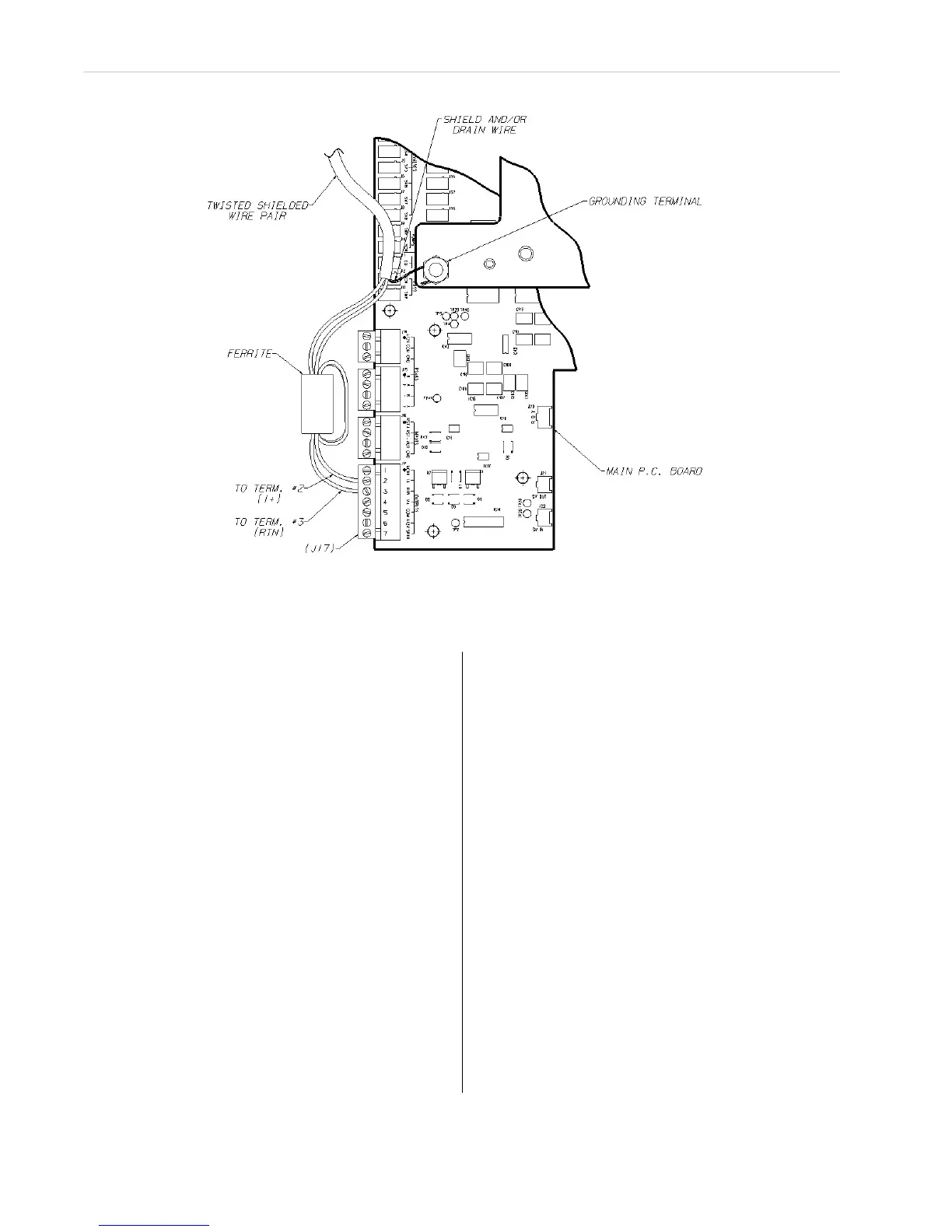

Figure 2-7.

Ferrite Bead Installation

NOTE: The maximum wire size that these

connectors can accept is #12 AWG.

Trouble Relay

There is one relay (the Trouble relay) within the

unit that indicates that a trouble or start-up

condition exists. This relay is configured from the

factory and operates differently than the alarm

relays. It operates in a normally-energized mode.

This relay is energized when the instrument is:

•

normally operating,

•

in the calibration mode, or

•

in the setup condition.

The relay is de-energized when:

•

a fault is detected,

•

the unit is in the start-up state, or

•

the main power is lost.

This means that power is no longer provided to

the relay coil. It is not possible to change the

configuration of the Trouble relay.

The relay connector function or identification:

•

NORMALLY OPEN (NO),

•

COMMON (COM),

•

NORMALLY CLOSED (NC)

as marked in FIGURE 2-6 refers to the relay

contacts as if the relay is de-energized or in the

trouble condition. A relay contact is provided

between the Normally Clo

sed (NC) and Common

(COM) position. This contact will be made in the

event that main power to the unit is lost or any

other trouble condition exists.

Trouble Relay Connection Wiring

The Trouble relay wiring should enter the unit

through one of the entries on the right side of the

unit. Connections are made at the internal

terminal strip labeled J29, positions 1, 2 and 3

(located on the right side of the circuit board -

FIGURE 2-6). The terminal portion of the

connector can be unplugged from the circuit

board for ea

sier wire connections. The maximum

wire size that these connectors can accept is

#12 AWG.

Loading...

Loading...