Chemgard Infrared Gas Monitor

•

A SPAN gas cylinder

•

Optional ZERO gas cylinder.

•

A ZERO gas cylinder may not be needed.

The Calibration Kit contains a ZERO gas scrubber

which can be used in place of a ZERO gas

cylinder if the ambient air around the Chemgard

Infrared Gas Monitor contains little or no

interfering gas.

CAUTION

The zero gas scrubber must be replaced

periodically because the filter can become

saturated by ambient gas vapors. The

frequency of replacement depends on the

concentration of the ambient gas vapors.

The SPAN or ZERO cylinders (if needed) may be

included with the Calibration Kit; cylinders shown

in TABLE 4-1 are available from MSA:

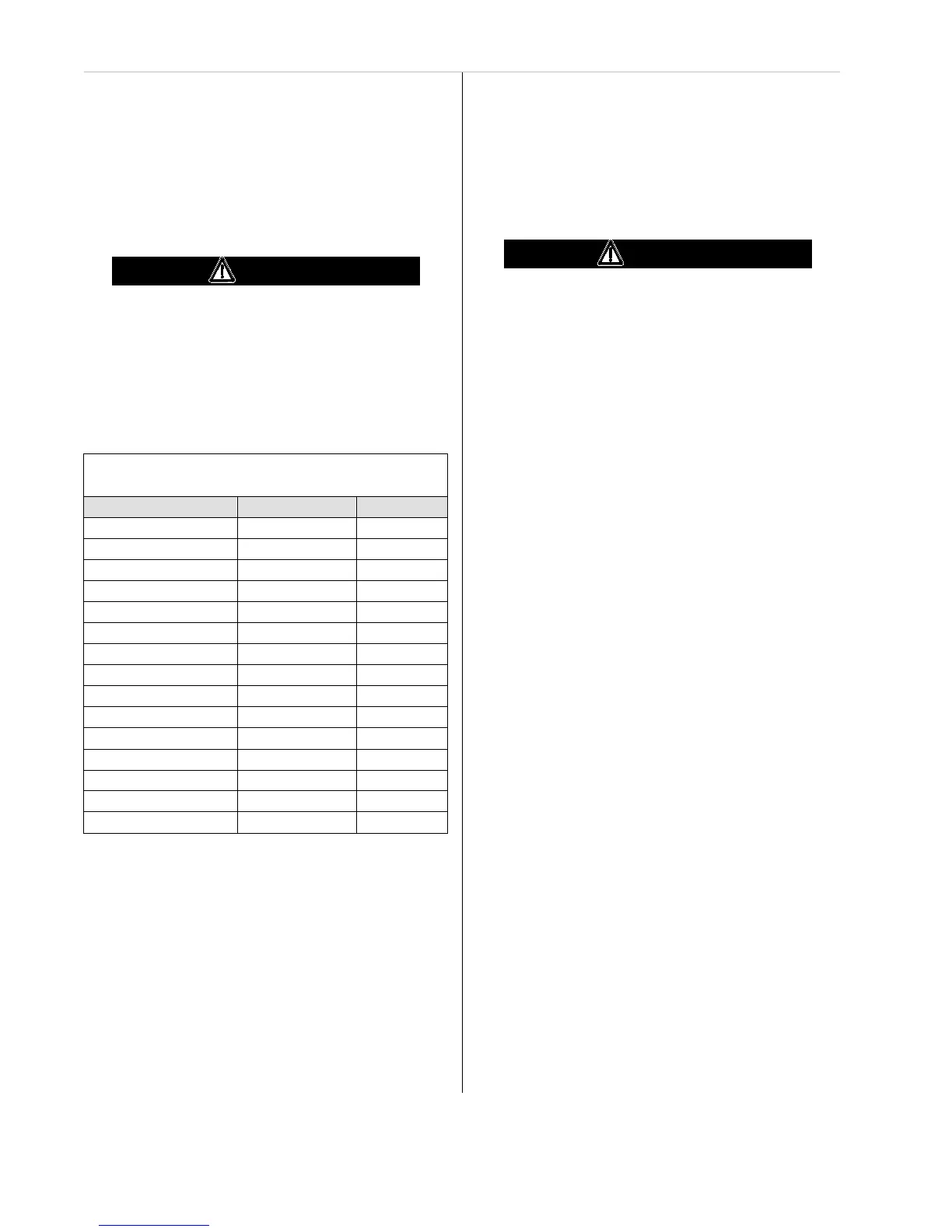

Table 4-1. Calibration Gas Cylinders

Carbon Monoxide 100 ppm 806734

Pentane 1000 ppm 10014894

R22 100 ppm 804868

R11 100 ppm 803499

Zero Air

801050

R113 100 ppm 804870

R134a 30 ppm 812787

R123 30 ppm 812784

Become familiar with the Calibration Kit

components (FIGURE 4-1).

For Carbon Monoxide,

Carbon Dioxide and Nitrous

Oxide Chemgard Monitors

An affect observed on these infrared monitors is

a reduction in signal at low relative humidities.

The gas sample being drawn into the instrument

MUST contain a humidity level greater than 0.3%

by volume. At 72°F (22°C), this would represent a

relative humidity level of approximately 10%.

To ensure that the sample is humidified, MSA

recommends placing an air-tight water bubbler in

the sample line. I

f the humidity level in the

sample stream will be above 0.3% by volume at

all times, the water bubbler is not necessary.

Care MUST be used to ensure that sufficient

water is present in the bubbler such that the

humidity level is greater than 0.3% by volume at

all times, including during calibration.

WARNING

Failure to properly humidify the sample at

all times can cause erroneous monitor

readings. If the instrument is not properly

humidified, the Chemgard Monitor may fail

to perform as designed and persons who

rely on this product for their safety could

sustain severe personal injury or death.

Calibration of the infrared sensor can be achieved

by following the calibration procedure in this

manual. The sample MUST be properly humidified

during the calibration procedure.

Chemgard Infrared Gas

Monitor identification

You must identify your unit as a single-point

monito

r or a multi-point monitor for proper

calibration gas connection. Refer to FIGURE 4-2

to help identify your unit.

Calibration Procedures

Before calibrating the Chemgard Monitor,

leak-check the sample line(s) connected to

the monitor:

1. Temporarily block the sample inlet at the

end-of-line filter(s) and verify that the

monitor gives a trouble alarm.

•

If the monitor is a Multipoint Sequencer,

the trouble alarm will not activate until the

blocked sampling point is selected by the

Sequencer.

2. After checking for leaks, remove the sampling

line for the Chemgard inle

t.

•

On Multipoint Monitors,

use sample inlet Point 1.

3. Attach the Calibration Kit connector assembly

to the inlet.

4. Before applying gases, familiarize yourself

with the calibration screens by stepping the

monitor through the whole sequence. Press

the keys in the following order:

Loading...

Loading...