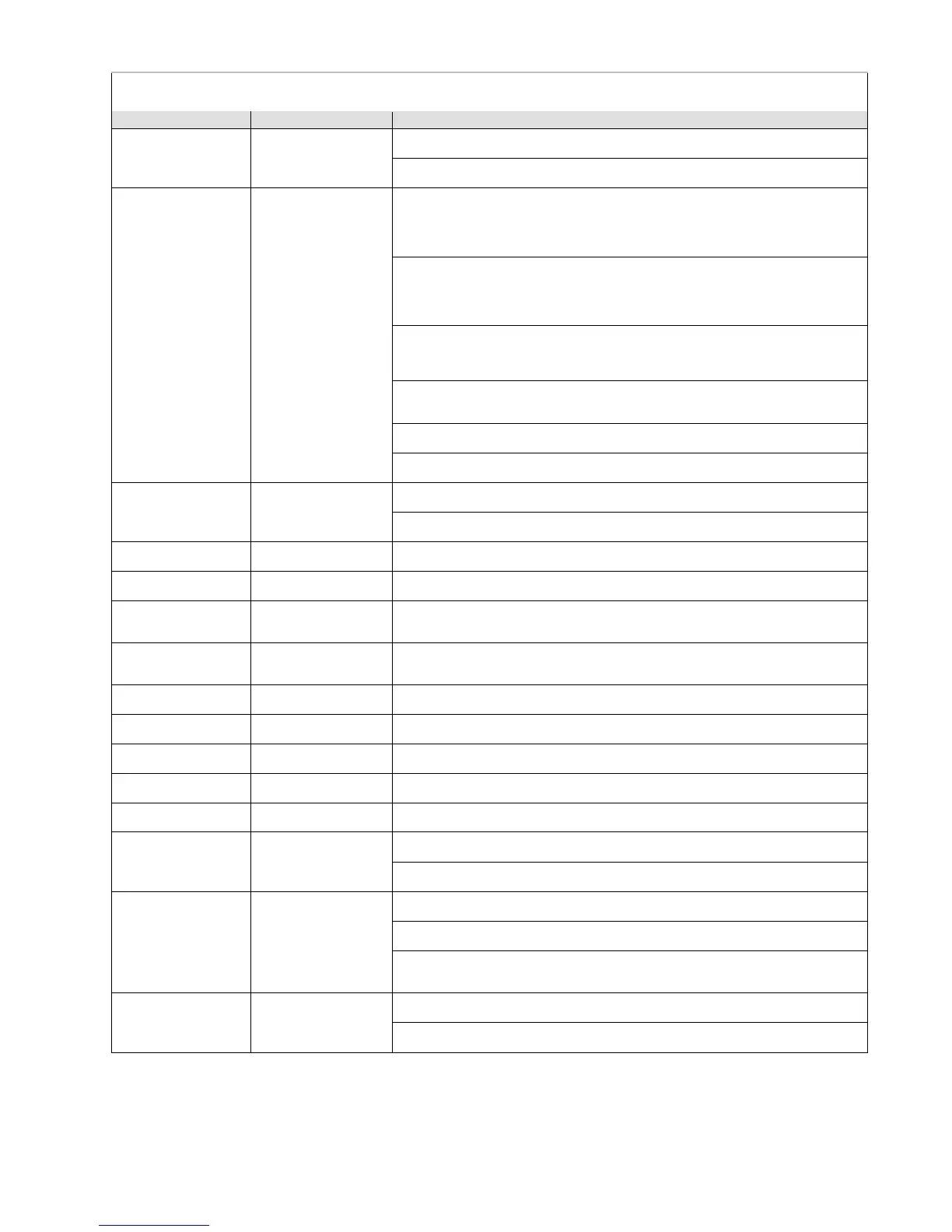

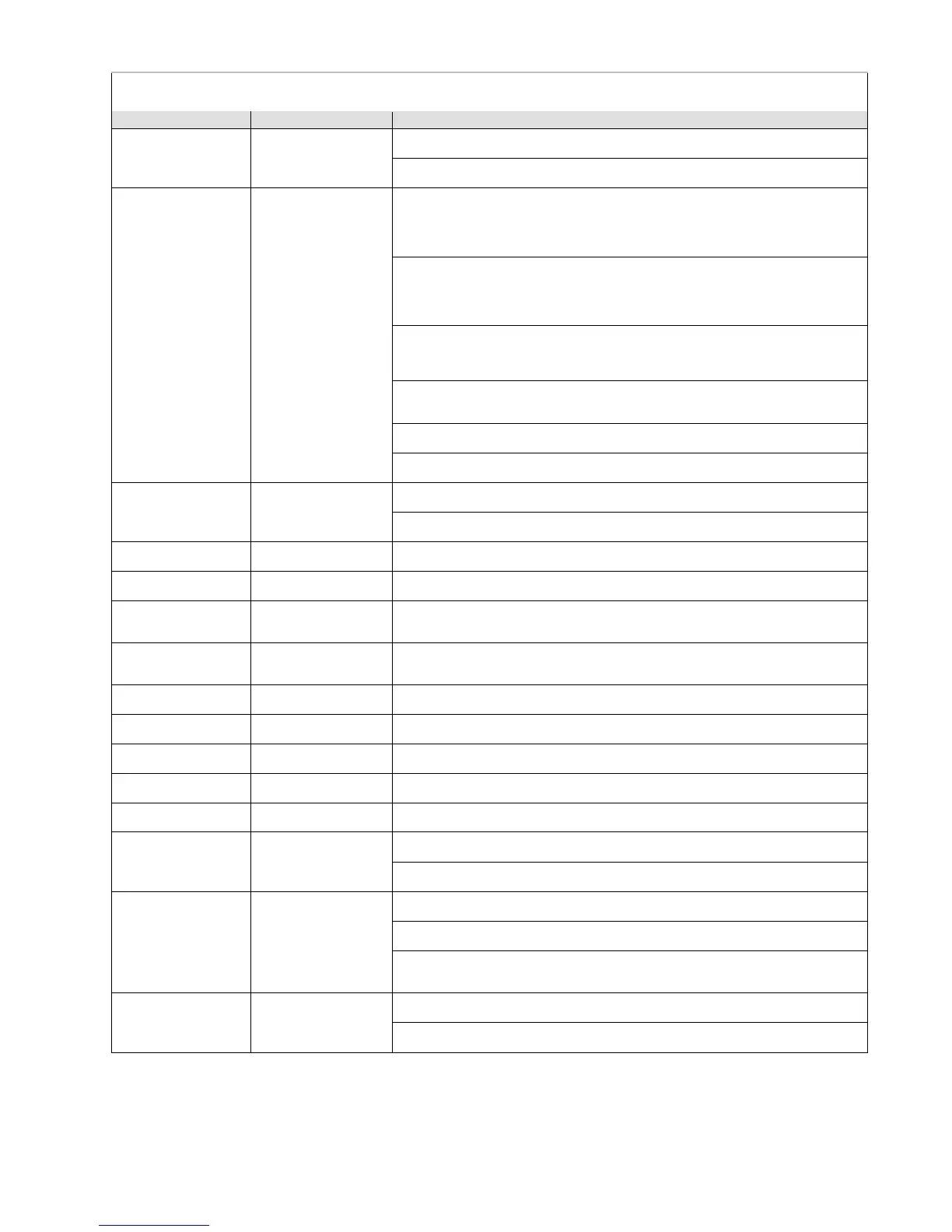

Chemgard Infrared Gas Monitor

Table 5-2. Troubleshooting Guidelines

Start bypass flow

failed

Leaky or blocked

bypass line at startup

of unit

1. Same as bypass flow failure. Check as above, turn unit off and restart unit.

2. Leak test the flow system and restart unit.

Sensor flow failed

Leaky or blocked

sample line

1. Remove all input lines to the unit.

Attach one line at a time to check for sample input.

Check all end of line filters. Sample flow failure is always the present point

being sampled.

2. Remove the optical bench cover.

Check the inlet fitting, tubing, sample filter, tubing to the optical bench inlet

fitting, outlet fitting from the optical bench, sample pressure switch, and sample

manifold tubing.

3. Check the sample pressure switch for 4 VDC ON and OFF switching.

Check the cable terminals and plug end at press/sample connector.

Replace pressure switch if necessary.

4. Check operation of all manifold sample valves.

Check the optical bench inlet and outlet valves.

5. Check the optical bench inlet and outlet valve connectors on J22 and J21.

6. Leak test the flow system.

Start sensor flow

failed

Leaky or blocked

sample flow line at

unit startup

1. Same as sensor flow failure. Check as above; turn unit OFF and re-start unit.

2. Leak test the flow system.

Case temperature

Main board

1. Return to MSA for service.

Case temperature

Case temperature is

o

1. Return to MSA for service.

Thermostat sensor

failed

Controls optical

bench inside

1. Replacement of optical bench requires MSA service.

Sensor temperature

range failed

Checks for

temperature range of

o

1. Replacement requires MSA service.

Humidity sensor failed

Checks H

2

O sensor

1. Return to MSA for service.

Infrared source failed

Checks the I of

1. Return to MSA for service.

Photo synchro failed

Checks the chopper

1. Return to MSA for service.

PA IR sensor failed

Checks the sensor

1. Return to MSA for service.

Memory protect

Checks checksum

1. Return to MSA for service.

External reset failed

Checks the external

reset button

1. If not used, check for jumper between RST minus and RST plus on J16.

2. If used, verify switch is wired normally closed.

Display failure

Display

communications

1. Check RS485 connector on J15, terminals 1 and 2.

2. Check for broken or cracked display.

3. Remove rear panel cover and check cables between the display and the

display board.

Audio alarm failure

Audio alarm

1. Check output terminals 6 and 7 on J17.

2. Check for faulty horn buzzer.

Loading...

Loading...