Chemgard Infrared Gas Monitor

Table 4-2. Calibration Sequence Screens

PROMPT: ALARMS ARE NOW OFF

6

NEXT

PROMPT:

SAMPLE POINT 1 TO BE USED

PROMPT: ADJUST OR OK READING

10

SPAN

PROMPT: GO INTO SPAN

PROMPT: ALARMS ARE NOW OFF

12

NEXT

PROMPT:

SAMPLE POINT 1 TO BE USED

PROMPT: ADJUST OR OK READING

16

NEXT

PROMPT: ALARMS ARE NOW

17 NEXT RETURNS TO NORMAL OPERATION

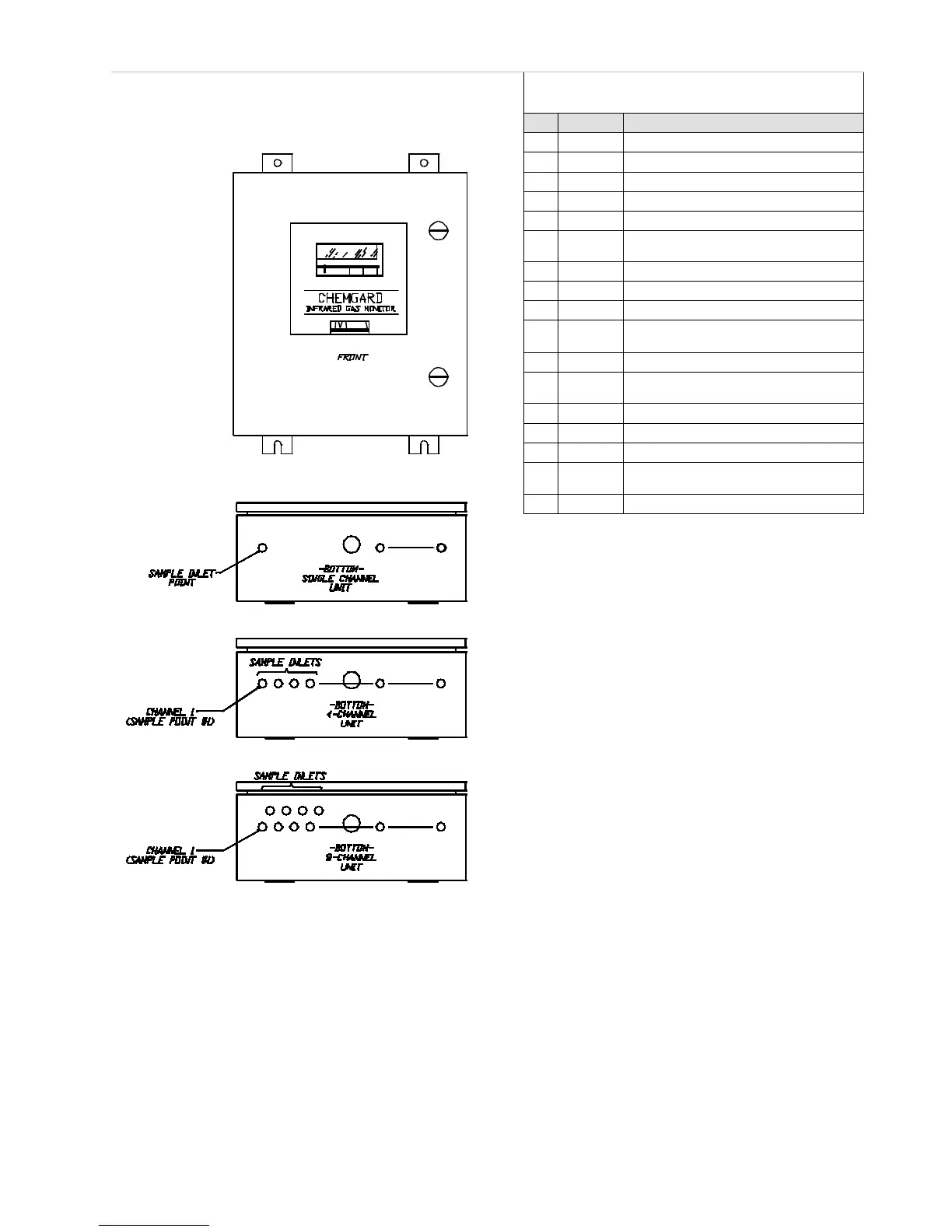

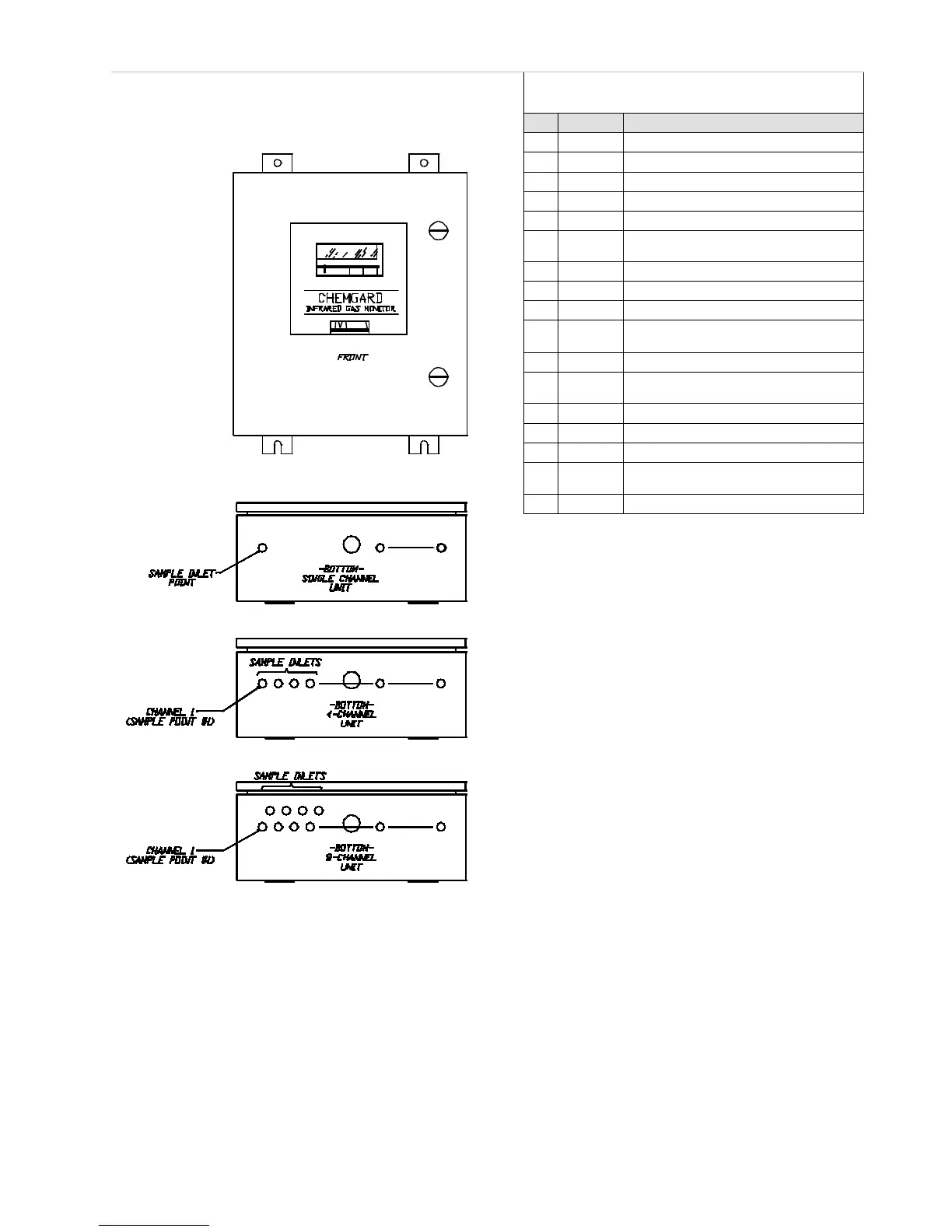

Figure 4-2.

Chemgard Models

•

When this sequence is done with zero and

span gases, adjust the zero and span

readings (if necessary) in TABLE 4-2

steps #9 and #15, respectively.

•

If adjustments are needed, press ADJ

to access the UP, DOWN and ENTER

keys; enter the zeroing and

spanning adjustments.

4. Zeroing the Monitor:

When zero gas is required, attach a zero

gas scrubber or zero gas cylinder to the

connector as shown in FIGURE 4-3.

NOTE: Use only the zero gas cylinder

on monitors calibrated for ammonia.

5. Spanning the Monitor:

When span gas is required, a span gas

cylinder must be attached to the connector

as shown in FIGURE 4-5.

NOTE: The span gas must be appropriate for

monitor calibration. For many

applications, a span gas cylinder of

the gas of interest is available from

MSA. If a span gas cylinder of the

specific gas is not available, MSA has

determined an appropriate synthetic

span gas. See TABLE 4-1 for calibration

cylinders available from MSA. If a

synthetic span gas is used, refer to the

calibration label on the inside of the

monitor door (FIGURE 4-6

).

Loading...

Loading...