• comes equipped with a special flow cap for use on the Toxgard

II Gas Monitor to ensure proper sensor sampling.

• provides notification via the Toxgard II Monitor LED display and

fault relays if a flow fault is detected.

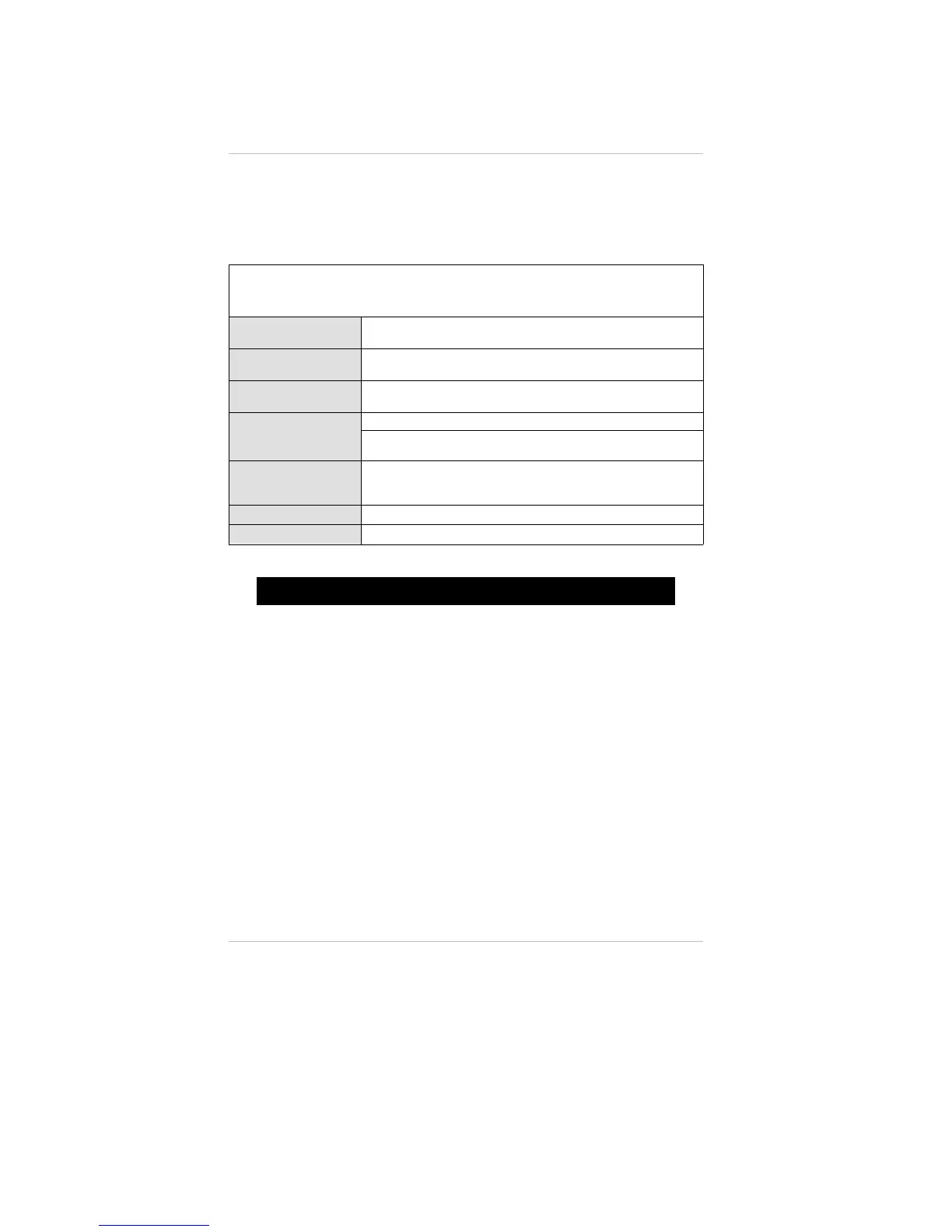

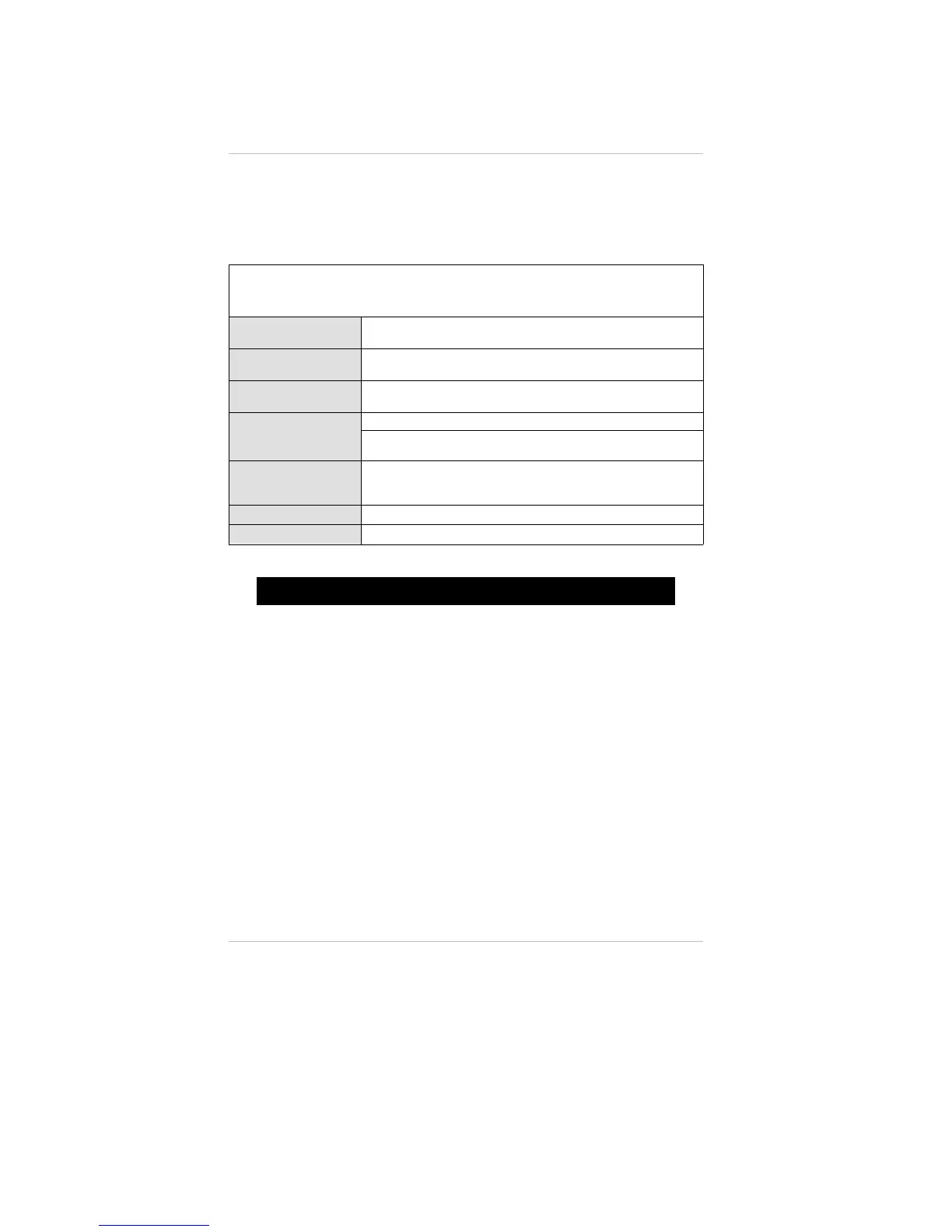

Table 1-1. Performance Specifications

for Toxgard II Pump or Aspirator Model

SAMPLE

TRANSPORT TIME

30 seconds at 0.5 lpm with 50 feet (15.25 meters) of

.180 (4.57 mm) ID sample tubing

NOMINAL SAMPLE

FLOW RATE

2 CFH (1 LPM)

MINIMUM SAMPLE

FLOW RATE

1 CFH (.500 LPM)

MAXIMUM SAMPLE

TUBING LENGTH

100 feet (30 meters); 3/16" ID (4.76 mm)

25 feet (7.5 meters) maximum for Chlorine, Nitrogen

Dioxide and Chlorine Dioxide

MAXIMUM

EXHAUST TUBING

LENGTH

20 feet (6 meters)

INLET FITTINGS

1/4" (6.35 mm) OD Tube Fitting

EXHAUST FITTING

1/4" (6.35 mm) OD Tube Fitting

"

WARNING

Only Remote Sensors with proper area ratings can be used in a

hazardous area. The Toxgard II Monitor cannot be installed in a

hazardous area. Otherwise, an explosion hazard will exist resulting

is a possible explosion, injury or death.

Installation of DC Pump or Aspirator

Sampling

Sample Line Placement

• Remove all protective packaging plugs and/or caps from gas

INLET, CALIBRATION and EXHAUST PORTS.

• In-line filter must be used in the sample line.

• MSA tubing is available (P/N 600771).

The pump or aspirator draws a gas sample to the Toxgard II

Gas Monitor sensor (FIGURE 1-1):

• Can be extended up to 100 feet (30 Meters) away from the

Toxgard II Gas Monitor.

Chapter 1, Set-up

1-6

Loading...

Loading...