Troubleshooting

45 AP-74700 – Rev. 1.0 – 10/03/2008

3.4.3.2 Media

toleration

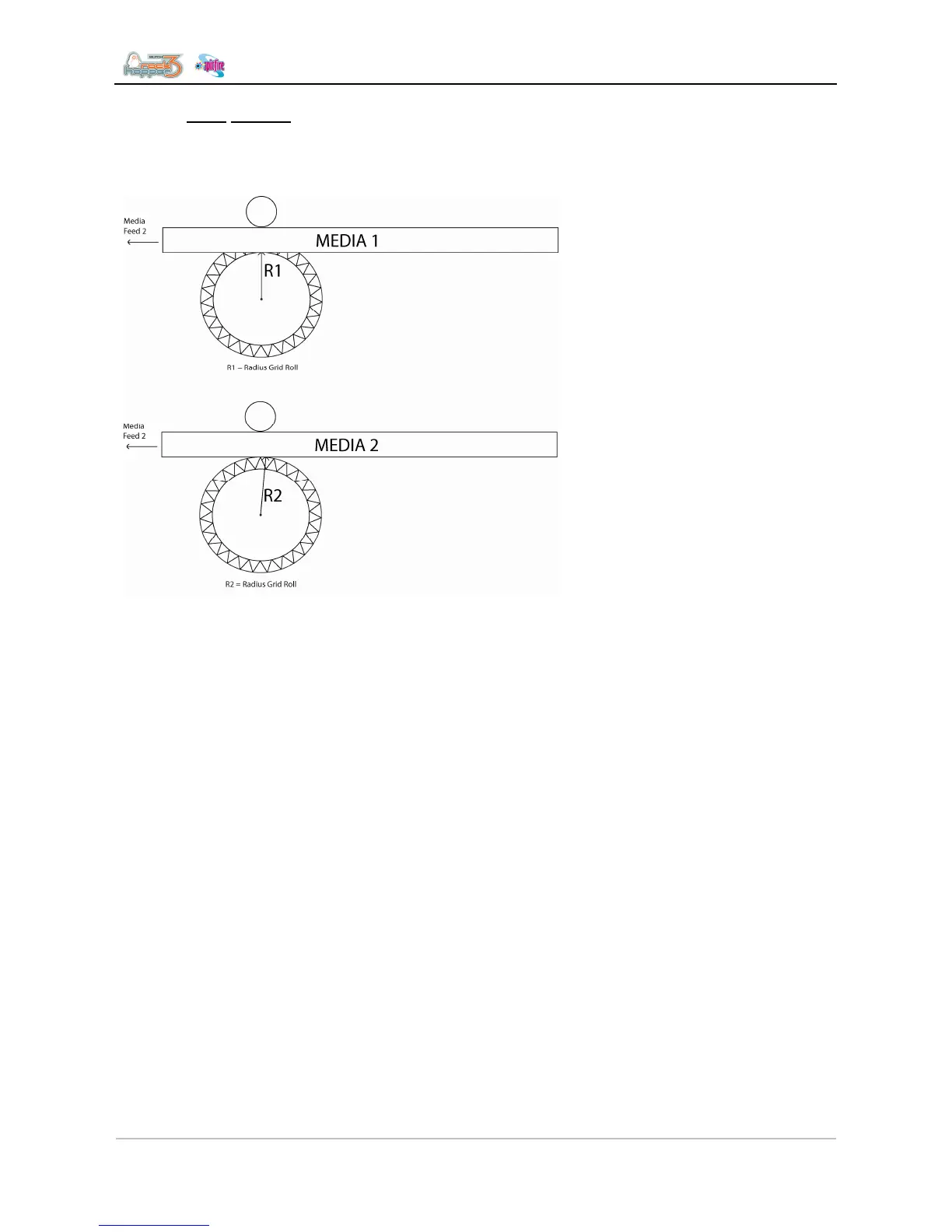

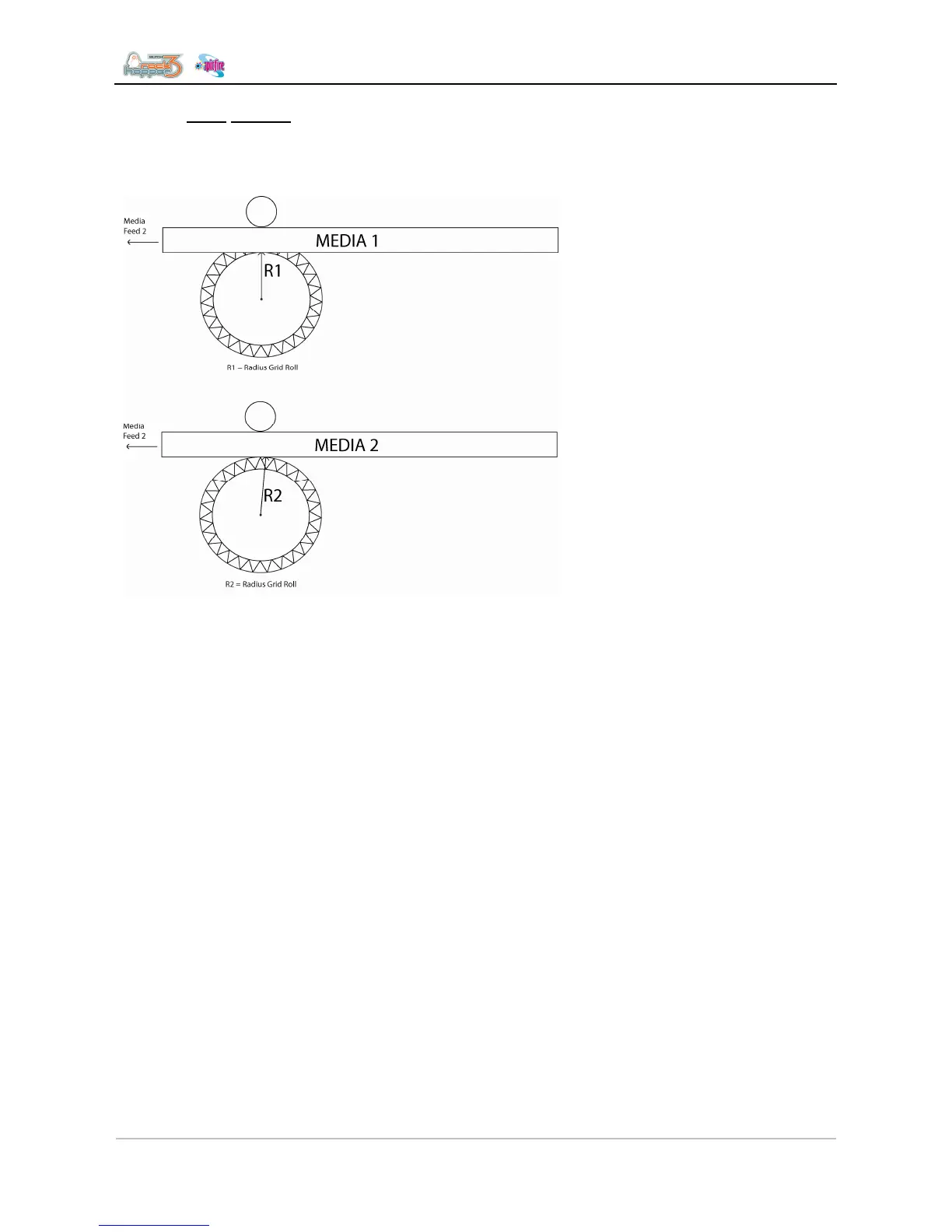

Depending of the media-type used, the radius of the Grid-rollers will change.

This is clearly explained in following illustration:

Media 1

Is a soft material or has a soft backing. Due to the softer backing, the coating on the grid-rollers is slightly

pushed inside the material. When the Grid Roll is turning, the media is feeding forward with radius R1.

Media 2

Is a hard material or has a hard backing. Therefore the grid rolls are pushed less inside the printing material.

When the Grid Roll is turning in exactly the same amount between every pass, the media moves more

forward than the case with Media 1.

The reason is because the circumference of this Grid-roll is bigger because of the bigger radius R2.

This theory proves that the distance-adjustment is strongly depending of the kind of material you like to print.

For this, each material needs at least once, a distance-adjustment calibration for achieving the most optimum

and fine-tuned media-feed movement between each print-pass!

Other factors like:

• Heater temperatures

• Use of the Take-up system

• The backing-type (explained here above), stiffness and friction

• The rollfeed-system

.. Will also have an impact in on the distance-adjustment accuracy!

Therefore a fine-tuning-mechanism exists, calling the “Distance Adjustment” or “Feed Adjust”. This distance-

adjustment adjustable in hundreds of a percentage, needs to be executed, for each new material-type, used

on the printer. This procedure can be done via the ‘distance adjustment’ procedure in “Ready to work Æ

media”

The distance-adjustment can also be adjusted “on the fly” during printing!

Loading...

Loading...