Operation Instructions Spitfire 65/90 Extreme

CHAPTER 5 : PREPARATIONS BEFORE PRINTING

56 AP-77140 – Rev. 1.1 – 05/04/07

5.3 I² TECHNOLOGY

Without weaving ON, an image is completed (formed) by printing a series of

complementary rectangular shaped stripes (bands, swaths, passes). Inherent to

classic inkjet printing is that ink drying effects, stepping mismatch, miss firing nozzles

show up in the printed image via ink bleeding and various types of banding. By

switching ON one of the weave patterns you will give the traditional rectangular print

swaths a wave-shaped look that will save you time and boost your output quality.

Difficult images will print smoother, banding will be suppressed (neutralized) and you

will have to spend less time fine-tuning your printer to create great looking output.

Moreover, when using wave-tuned profiles, you will be able to boost your printer’s colour gamut as the i²

(intelligent interweaving) technology allows depositing more ink, helping you to achieve higher colour

densities.

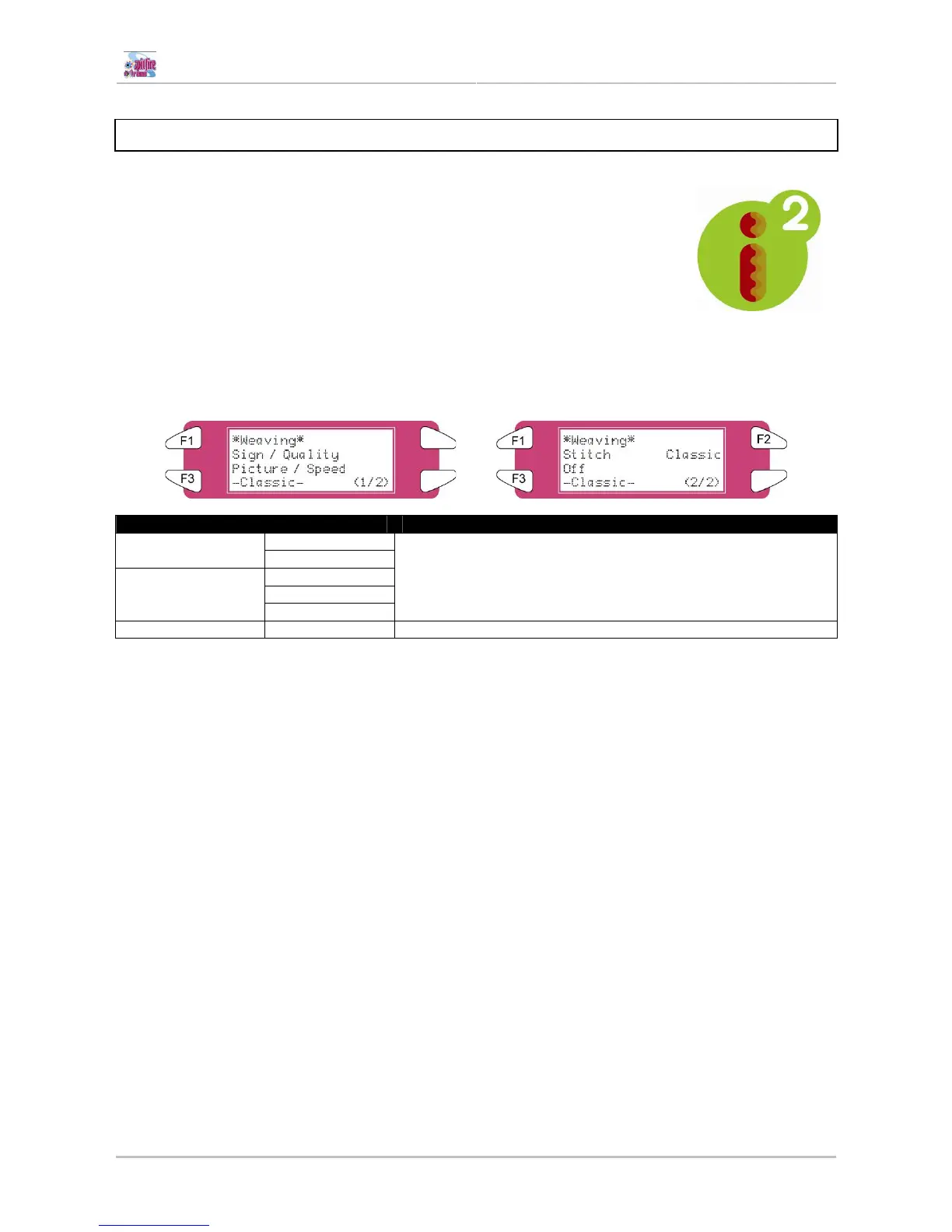

Setup items Parameters Description

Sign / Quality Weaving (1/2)

Picture / Speed

Stitch

Classic

Weaving (2/2)

Off

Please refer to the table below to know what the different weaving

forms are and which one to use.

Weaving (1/2 – 2/2) - [CANCEL] key: To shift to the previous hierarchy menu.

Loading...

Loading...