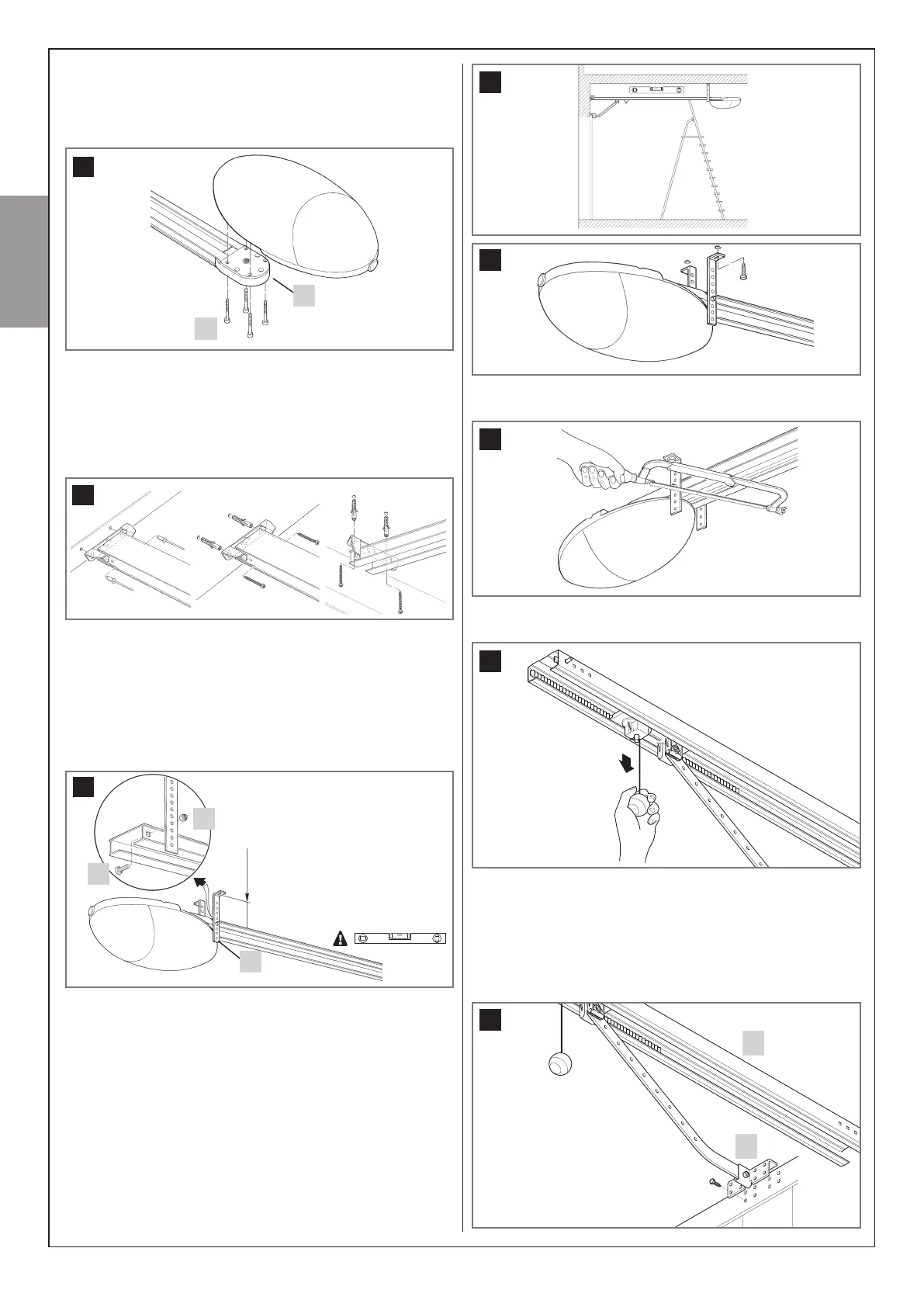

3.2.2 – Fitting the gearmotor to the guide

01. FittheAVIO500gearmotoroutputshafttotheguidehead[A]

andsecureusing4M6.3x38screws[G](g. 14).Thegearmotor

rotatesandcanbepositionedinthreedifferentways(g. 3).

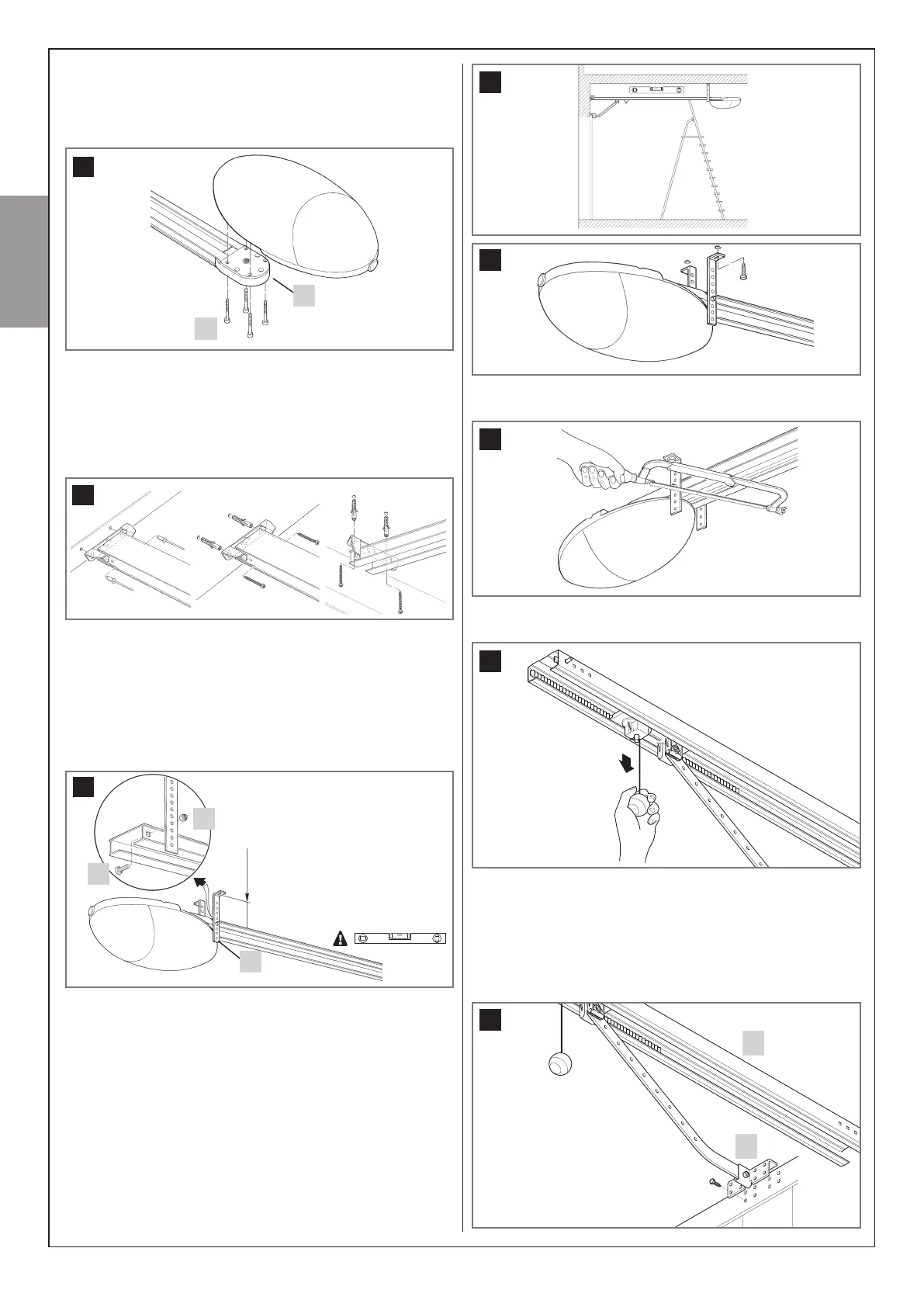

3.2.3 – Mounting the gearmotor to the ceiling

01. OnthebasisofdistancesAing. 2,tracethetwoxingpoints

ofthefrontguidebracketatthecentreofthedoor.Onthebasis

ofthetypeofsupportsurface,thefrontbracketcanbexedwith

rivets,plugsorscrews(g. 15).IfdistancesA,BandC(g. 2 and

3)aresufcient,thebracketcanbexeddirectlyontotheceiling.

15

02. Afterdrillingtheholesintherelevantpoints,leavethegearmo-

torheadontheground,payattentionnottodamageit;thenlift

theguidefromthefrontsectionandpositionithorizontally(usea

bubblelevel)andxitbyusingtwoscrews,plugsorrivets,ac-

cordingtotheinstallationsurface.

03. Securethebrackets[H]usingthescrews[I]andnuts[L],se-

lectingtheholemostsuitedtoensuredistanceB,asshownin(

g. 16)

H

L

I

B

0÷400mm

16

04. Usingaladder,liftthegearmotoruntilthebracketsaretouch-

ingtheceiling.Tracethedrillingpointsandthenreturnthegear-

motortotheground.

05. Drill at theoutlined points and then, using a ladder, lift the

gearmotoruntilthebracketsareplacedagainstthedrilledholes

(g. 17)andsecureusingscrewsandplugssuitedtothesupport

surface(g. 18).

A

G

14

17

18

06. Ensurethattheguideisperfectlyhorizontal,thencutoffthe

excesssectionofthebracketswithasaw(g. 19).

19

07. Withthedoorclosed,pullthecordtoreleasecarriagefrom

theguide(g. 20).

20

08. Slidethecarriageuntilthedoorconnectingbracket[N](g.

21)ontheupperedgeofthedoorisperfectlyperpendicularto

theguide.

09. Thenxthedoorattachmentbracket[N]withscrewsorrivets

(g. 21).Usescrewsorrivetssuitableforthedoormaterialand

checkthat theycansupportalltheeffortrequiredtoopenand

closethedoor.

N

O

21

10–English

English

Loading...

Loading...