05.

THEDOORPERFORMS

AFULLCLOSING

MOVEMENT

Theyellow“set”LED

lightispermanently

on

06.

THEDOORPERFORMS

A FULL OPENING

MOVEMENT

Theyellow“set”LED

lightispermanently

on

07.

THEDOORPERFORMS

AFULLCLOSING

MOVEMENT

Theyellow“set”LED

lightispermanently

on

08.

THEDOORPERFORMS

A FULL OPENING

MOVEMENTWITH

SLOWDOWNS

Theyellow“set”LED

lightispermanently

on

09.

THEDOORPERFORMS

AFULLCLOSING

MOVEMENTWITH

SLOWDOWNS

Theyellow“set”LED

lightturnsoff

10.

ENDOFTHE

PROGRAMMING

PROCEDURE

If the “FORCE” knob is adjusted, the automation’s

movement must be reprogrammed.

The red “Error” LED flashes during the automation’s

movement when a mechanical stress point is detected (this

corresponds to increased motor effort). Adjust OBSTACLE

and FORCE knobs (slightly turn them clockwise) to solve

this and check gate mechanics if necessary.

STEP 7

Thesearethemostimportantoperations,designedtoguarantee

themaximumsafetyandreliabilityoftheautomationsystem.

Thetestingprocedurecanalsobeusedasaperiodiccheckof

thedevicesthatmakeuptheautomation.

The testing and commissioning operations must be

performed by qualied and experienced personnel who

must establish what tests should be conducted based on

the risks involved and verify the compliance of the system

with applicable regulations, legislation and standards, in

particular with all the provisions of EN standards 12445

and 12453 which establish the test methods for sectional

and overhead door automation systems.

7.1 – TESTING

1 Make sure that the provisions contained in chapter 1

“WARNINGS” have been carefully observed.

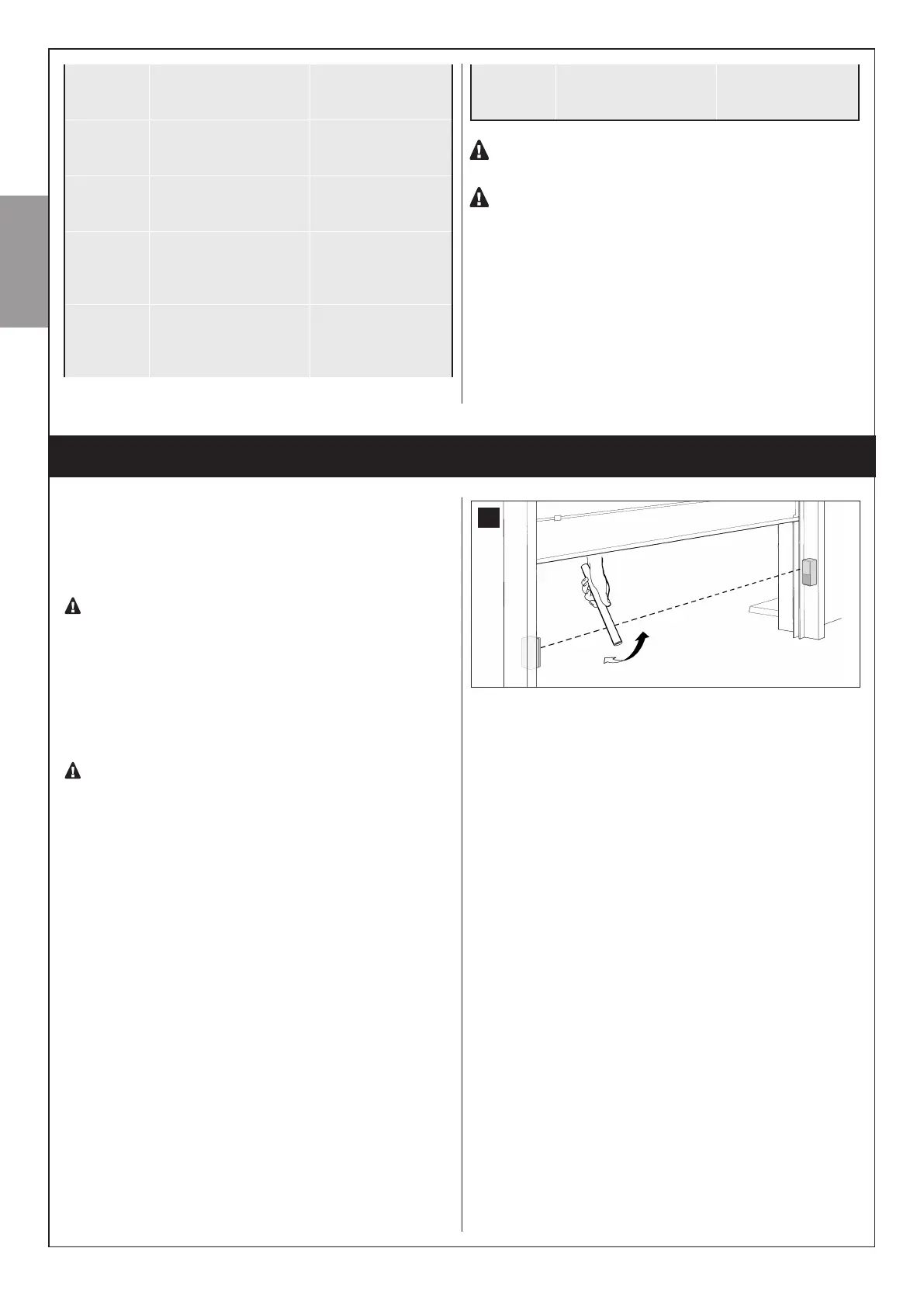

2 Usingtheradiotransmitter,testtheopeningandclosingofthe

doorandmakesurethatthedoormovesintheintendeddirec-

tion.

Thetestshouldbecarriedoutanumberoftimestomakesure

thatthedoormovessmoothly,thattherearenopointsofexces-

sivefrictionandthattherearenodefectsintheassemblyor

adjustments.

3 Checktheproperoperationofallthesafetydevices,onebyone

(photocells,sensitiveedges,etc.).

4 Tocheckthephotocells(ifprovided),passa5cmdiameter,

30cmlongcylinderontheopticalaxis,rstnearTX,thennear

RXandnallyatthemid-pointbetweenthemandmakesure

thatinallthesecasesthedeviceistriggered,switchingfromthe

activetothealarmstatusandvice-versa;nally,thatitcausesthe

intendedactioninthecontrolunit,forexample:thatitcausesthe

reversalofthemovementduringtheclosingmanoeuvre.

TESTING AND COMMISSIONING

33

5 Thecontrolofthecorrectobstacledetectionisperformedwith

the700x300x200mmtestparallelepipedwith3blacksidesand

3polishedwhiteormirroredsides,accordingtotheEN

12453

standard.

6 MeasuretheimpactforceaccordingtoENstandards12453.If

“motorforce”controlisusedtoassistthesystemforthereduc-

tionoftheimpactforce,trytondtheadjustmentthatgivesthe

bestresults.

7 Ensurethattheentiremechanismiscorrectlyadjustedandthat

theautomationsysteminvertsthemanoeuvrewhenthedoorcol-

lideswitha50mmhighobjectontheoor.

8 Ensurethattheautomationpreventsorblockstheopening

manoeuvrewhenthedoorisloadedwithamassof20kg,xedin

themiddleofthedoor’sloweredge.

7.2 – COMMISSIONING

The commissioning operations can be performed only

after all the tests have been successfully carried out. Par-

tial commissioning or implementation of “temporary” con-

ditions are not permitted.

1 Preparethetechnicaldocumentationfortheautomation,which

mustincludeatleast:assemblydrawing(e.g.gure1),wiringdia-

gram(e.g.gure65),analysisofhazardsandsolutionsadopt-

ed,manufacturer’sdeclarationofconformityofallthedevices

installed.ForAVIOuseAnnex1“CEDeclarationofConformityof

theAVIOcomponents”.

2 Postalabelonthedoorprovidingatleastthefollowingdata:type

ofautomation,nameandaddressofmanufacturer(personrespon-

sibleforthe“commissioning”),serialnumber,yearofmanufacture

and“CE”marking.

18–English

English

Loading...

Loading...