Revision 2

9.

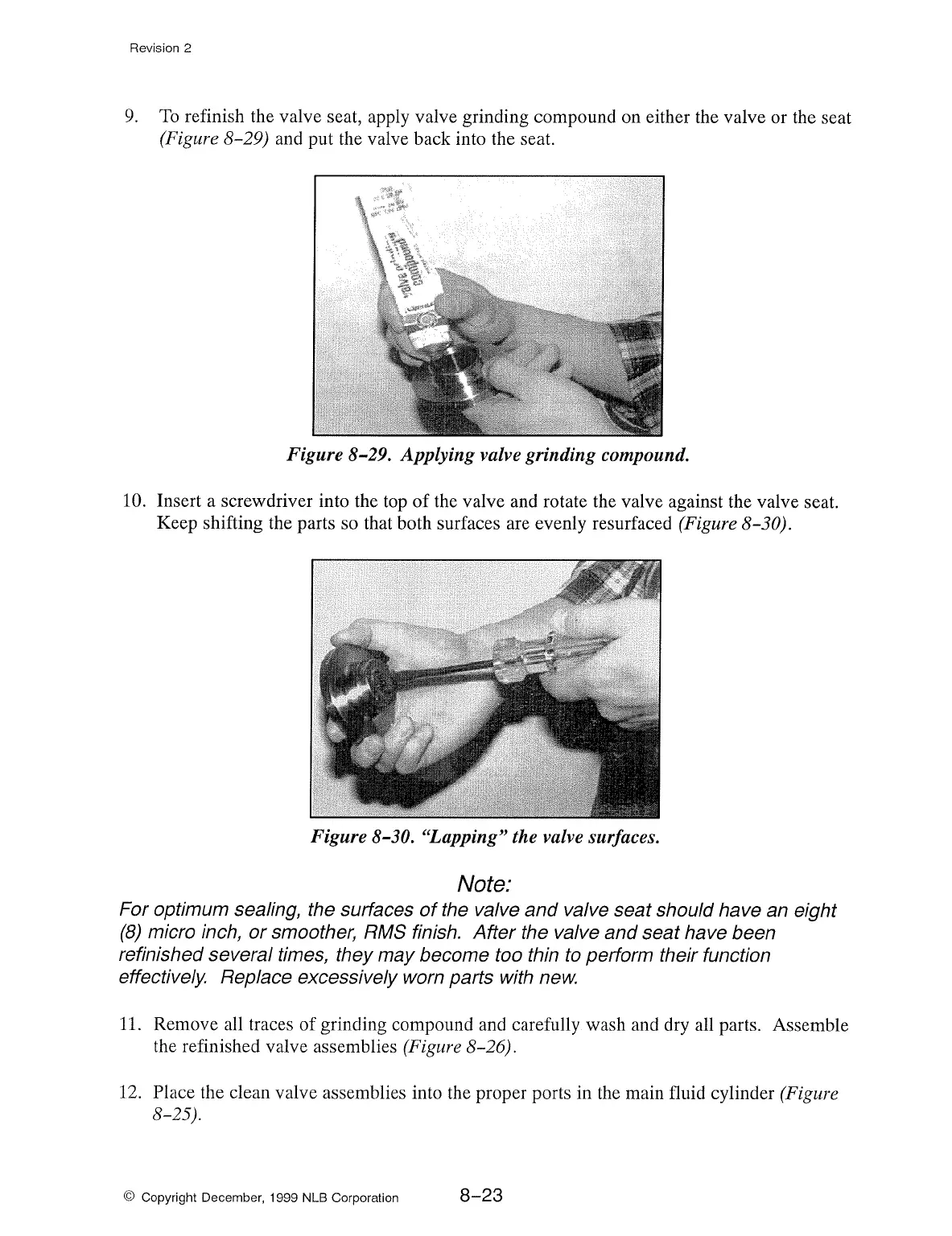

To

refinish the valve seat, apply valve grinding compound on either the valve or the seat

(Figure 8-29) and put the valve back into the seat.

Figure 8-29. Applying valve grinding compound.

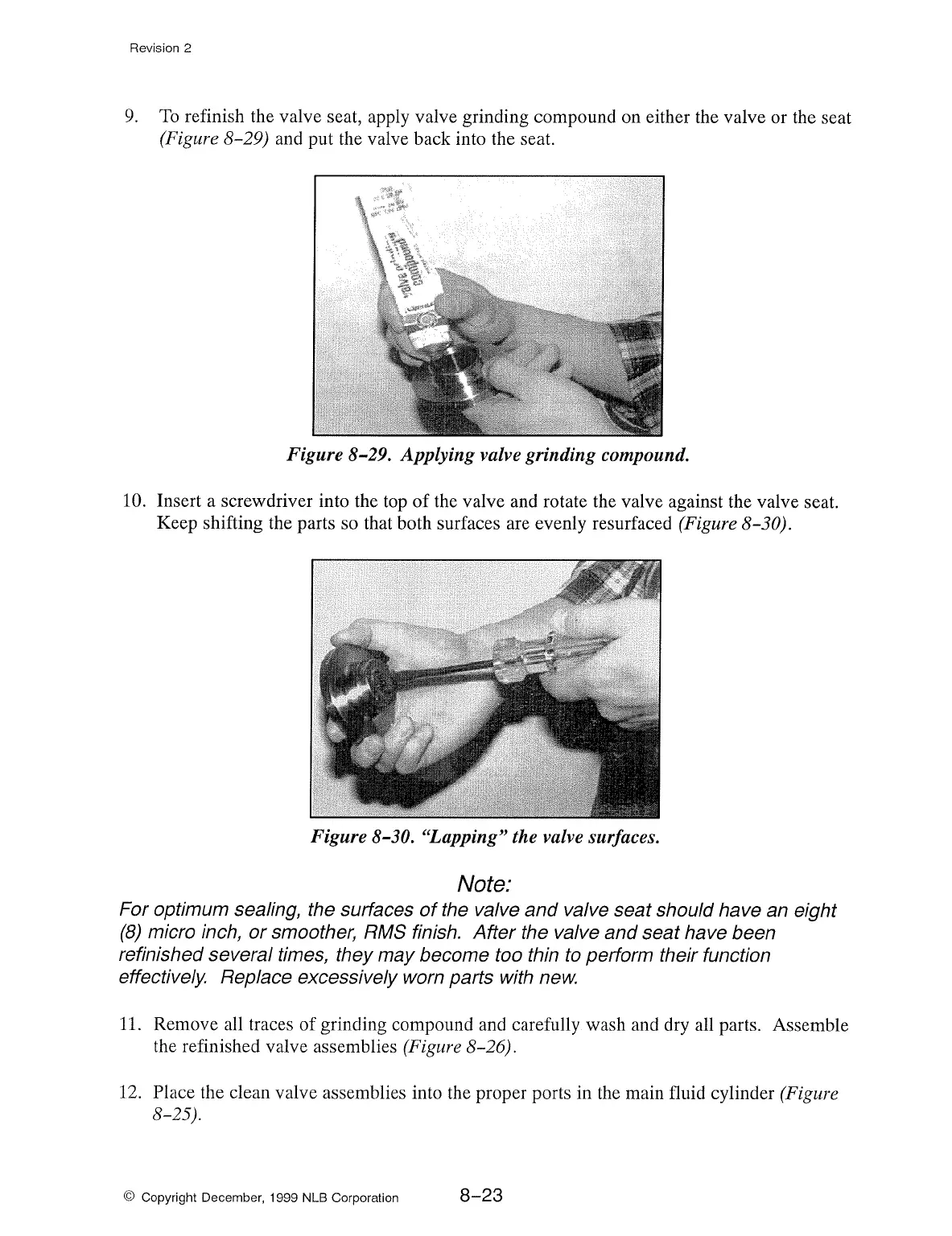

10. Insert a screwdriver into the top

of

the valve and rotate the valve against the valve seat.

Keep shifting the parts so that both surfaces are evenly resurfaced

(Figure 8-30).

Figure 8-30. "Lapping" the valve surfaces.

Note:

For optimum sealing, the surfaces

of

the valve and valve seat should have an eight

(8)

micro inch,

or

smoother, RMS finish.

After

the valve and seat have been

refinished several times, they may become too thin

to

perform their function

effectively Replace excessively worn parts with new.

11.

Remove all traces

of

grinding compound and carefully wash and dry all parts. Assemble

the refinished valve assemblies

(Figure 8-26).

12.

Place the clean valve assemblies into the proper ports in the main fluid cylinder (Figure

8-25).

© Copyright December, 1999 NLB Corporation

8-23

Loading...

Loading...