10-019116-01EN, Rev. 2, January 2021

Appendix C66

— Each sample is determined to be one of seven possible base alloys (Table 13

on page 66).

— The analyzer applies the residual grade/base-specific residual limits from the

matching residual grade.

2. These residual or “alloy-base-specific” limits are applied when an element is

detected in a specific grade.

— But, the nearest grade match has no specification for that element, and;

— The concentration of the sample is less than the max limit specified by the

matching residual grade.

3. When the conditions for step 2 are met, the element reported on the Vanta iX

screen:

— Is labeled as a residual material in the grade comparison table

— The grade match; however, is not penalized.

Practical advantages of the Residuals settings approach

• Faster sorting

• Fewer ambiguous or incorrect matches

• Improved grade library integrity

• Prominent labeling of residual elements

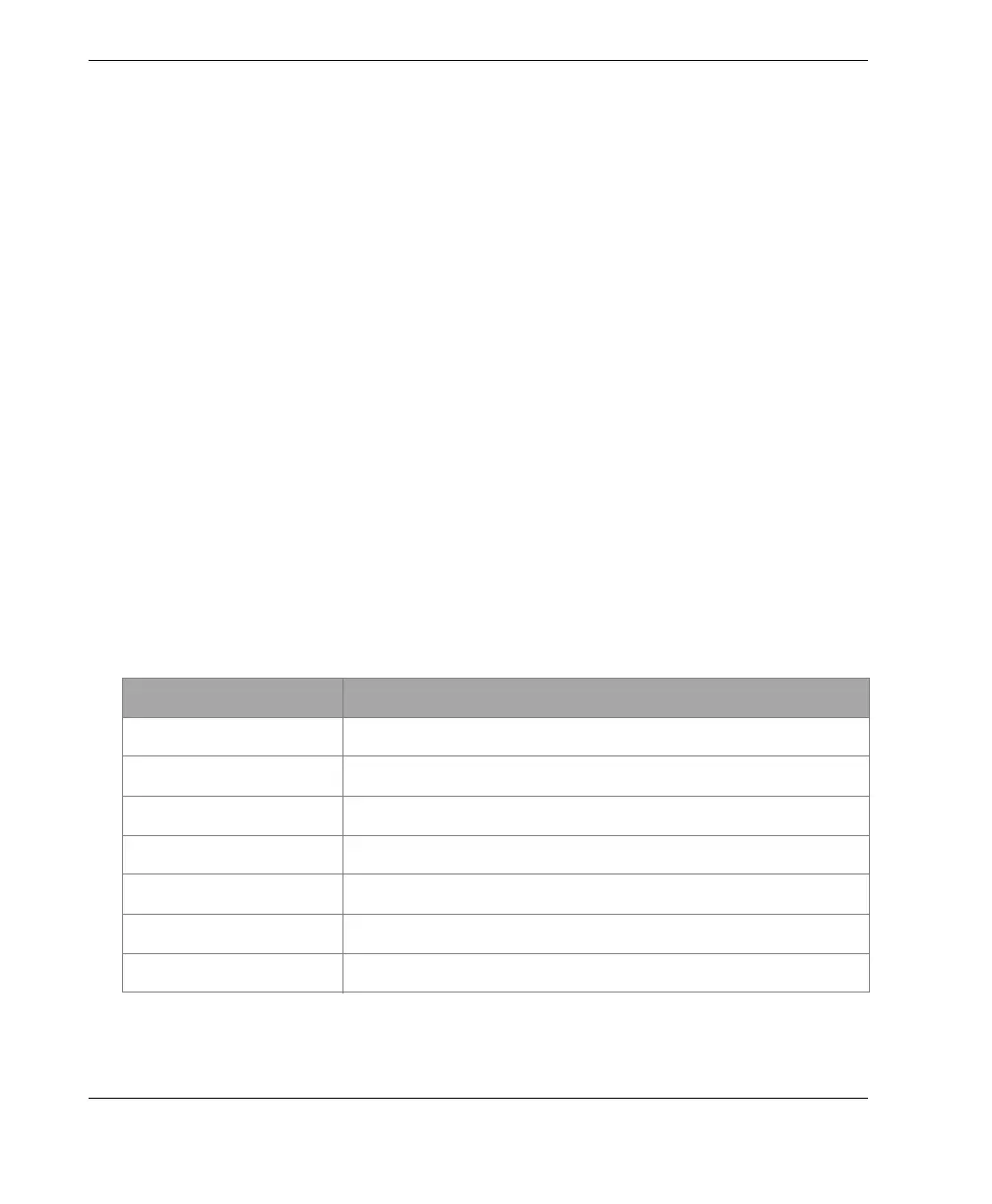

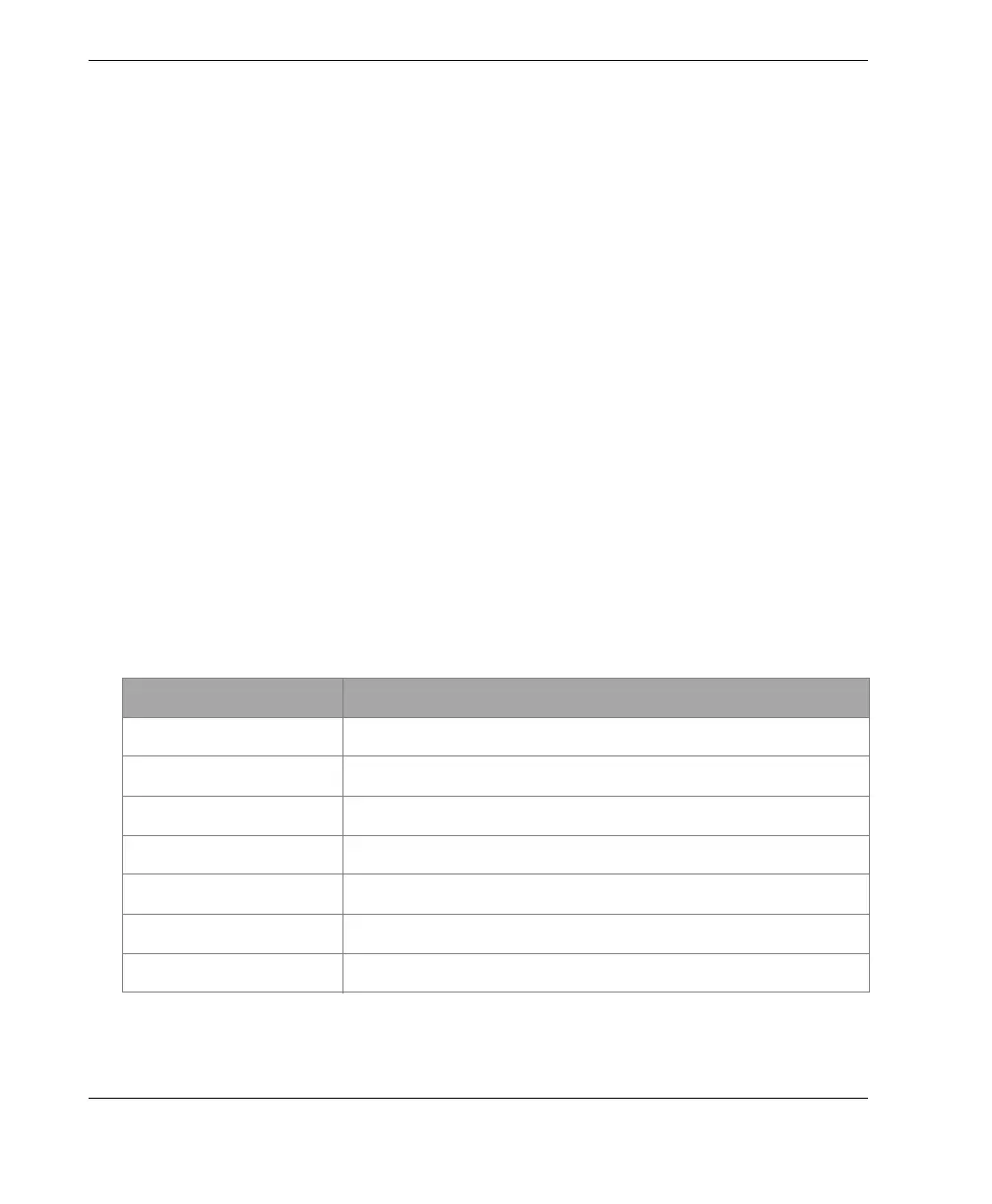

Table 13 Residuals settings base alloys

Alloy base Common residual elements

_AlAlloyBase Pb, Bi, Sn, Fe, Cu, and Zn.

_CoAlloyBase Al, Ti, V, Cu, Nb, Ta, and Zr.

_CuAlloyBase S, As, Ag, Sb, and Sn; not as common Pb, Co, and Ni.

_FeAlloyBase V, Co, Cu, Ni, and As; sometimes Si, W, and Nb.

_GenericAlloyBase V, Co, Cu, Ni, and As; sometimes Si, W, and Nb.

_NiAlloyBase V, Co, W, Zr, and Nb; sometimes Ta, Mo, Cr, and Cu.

_TiAlloyBase Fe is common; Cu and Si show up at low levels.

Loading...

Loading...