63

Safety Device Function Blocks Section 3-5

Machine’s Dangerous Area is on the Opposite Side of the Operator (Figure 2):

Note In the above example, limit switch 1 (S1) is wired to Si0 on the G9SP-series

Controller and limit switch 2 (S2) is wired to Si1. Set the dual channel mode

for local inputs in the G9SP-series Controller to dual channel complementary.

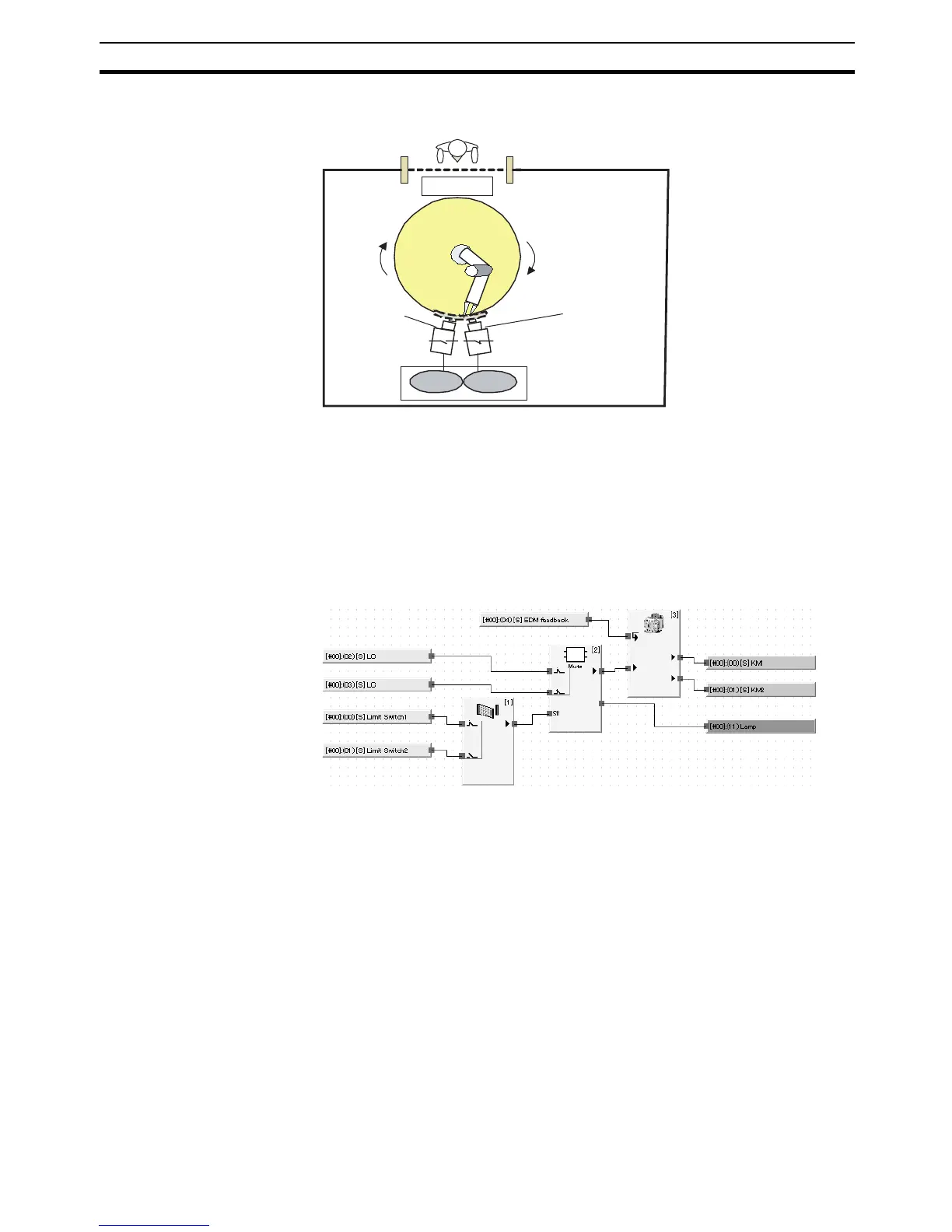

Program Example

Limit switches 1 and 2 connected to Si0 and Si1 on the G9SP-series Control-

ler are connected to Muting Signal 11 of the Muting function block through the

Safety Gate Monitoring function block.

Note Limit switches 1 and 2 are set to the dual channel complementary setting for

local inputs to evaluate the input data from the two switches.

Note The Safety Gate Monitoring function block is used as a function block for the

limit switches. Set the input type of the Safety Gate Monitoring function block

to Dual Channel Complementary (1 pair).

Muting Sequence

1. In figure 1 above, N.O. limit switch 1 is OFF and N.C. limit switch 2 is ON.

In addition, the light curtain is not obstructed, so the Output Enable signal

is ON. Muting Signal 11, which inputs the dual channel complementary

signal for limit switches 1 and 2, goes OFF.

2. As the robotic arm rotates, limit switch 1 goes ON and limit switch 2 goes

OFF as shown in figure 2. Muting Signal 11, which inputs the dual channel

complementary signal for limit switches 1 and 2, goes ON, so muting is en-

abled, and the Muting Status goes ON.

3. At this point, the Output Enable signal is kept ON even if the Safety Light

Current is obstructed so the operator can access the work platform.

Guard fence

Light curtain

Light curtain

Operator

Limit switch 1

(N.O. contact)

Limit switch 2

(N.C. contact)

ON

OFF

Si1

Si0

Work platform

G9SP-series

Controller

Loading...

Loading...