5-23

CHAPTER 5 Periodic Inspection

3. R-axis

1) Prepare the following tools and items.

• Harmonic grease 4B No.2

• Waste cloth (rag)

• Phillips-head screwdriver

• Hex wrench set

• Screw Lock (thread sealant)

• Torque-limiting wrench

• Adjustable wrench or spanner

• Replacement parts (See table below.)

Replacement parts

Parts name Type No .

OMRON Parts No.

Note

Harmonic drive

Edge seal

SHF-14-50

KN3-M1821-001

S53(JIS)

KN3-M1895-000 Lower part of harmonic drive

O-ring

Cross section diameter: 0.80mm x Inner diameter: 23.70mm

Cross section diameter: 0.60mm x Inner diameter: 37.10mm

KN3-M181H-000

KN5-M181G-000

For wave generator

Supplied with harmonic drive

VR18A

KN3-M1886-000

2) Turn off the controller.

3) Place a sign indicating that the robot is being inspected, to keep others from

operating the controller switch.

4) Enter the safeguard enclosure.

5) Remove the Y-axis arm upper cover. Place the cover on the robot base

(pedestal) side with the machine harness still connected.

Refer to "7 Removing the Robot Covers" in Chapter 4 for removing the

covers.

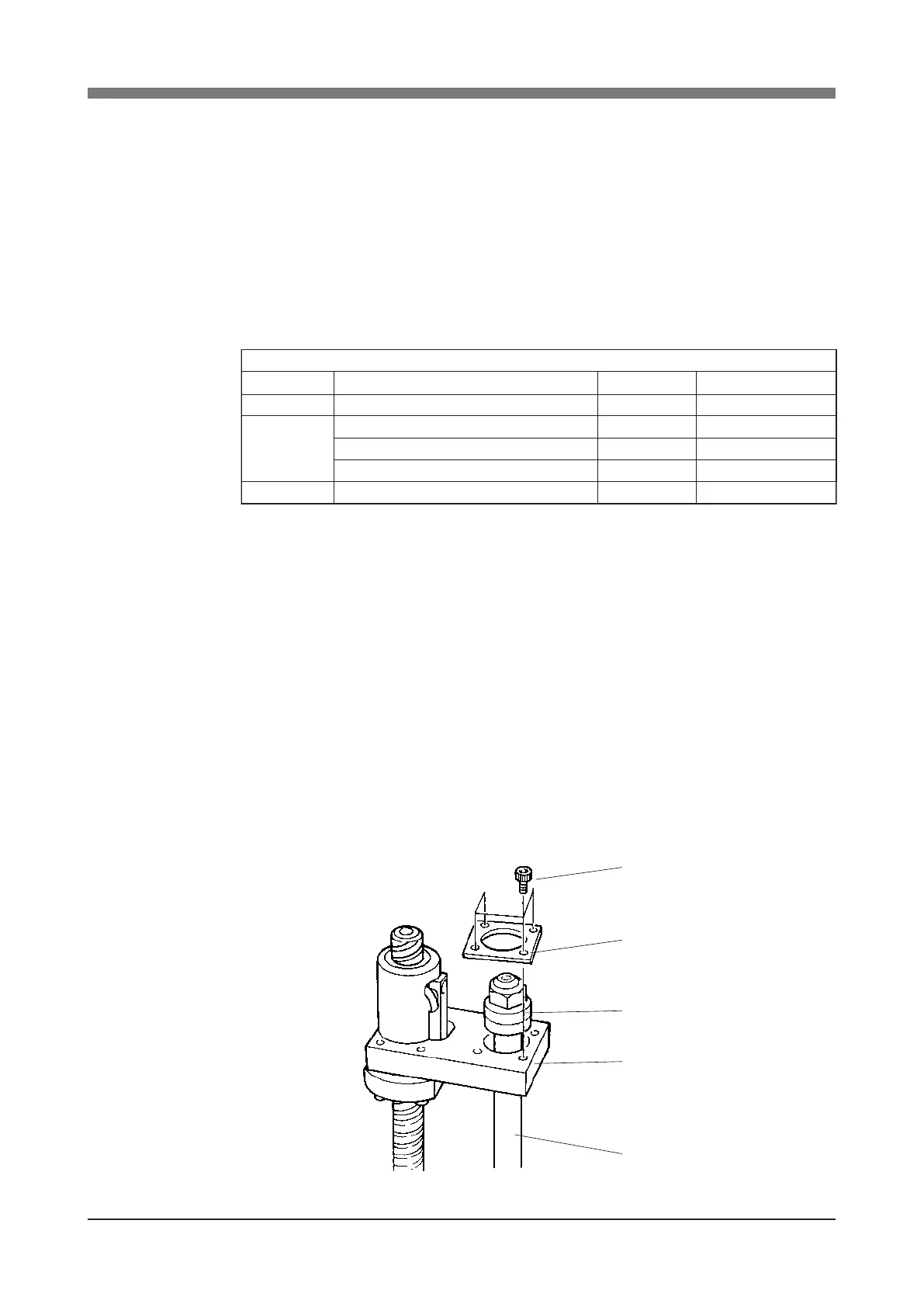

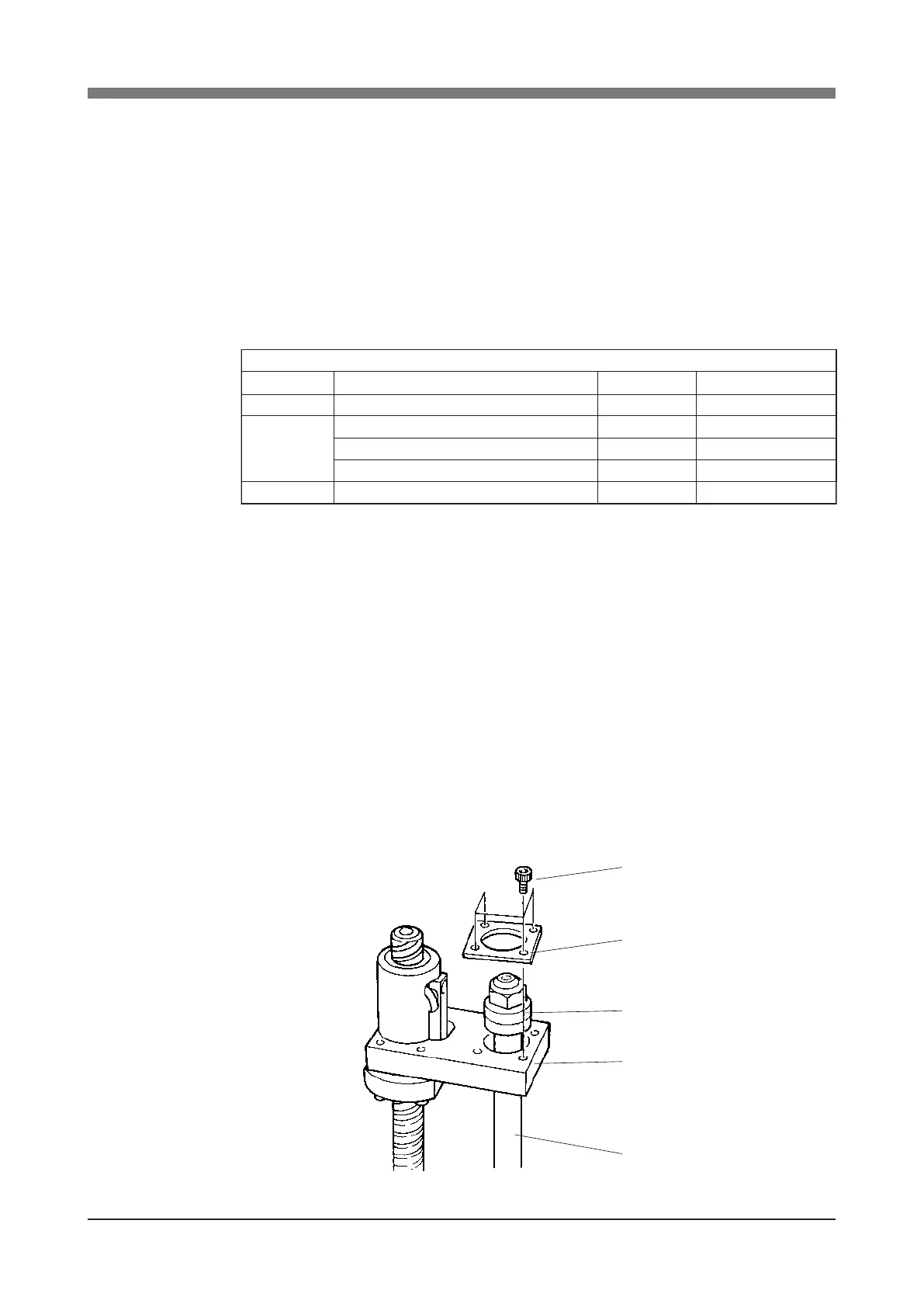

6) Remove the bolts (M4×8L, 4 pieces) securing the bearing to the upper end

of the spline and remove the spline mount plate, spline and bearing from

the holder. (See Fig. 5-11.)

M4×8

Spline mount plate

Bearing

Holder

Spline shaft

Fig. 5-11

Loading...

Loading...