Note As the cable betweenthe Inverterandthe motor becomes longer, a high-frequen-

cy leakage current from the cable increases, causing the Inverter output current

to increase as well. This may also affect peripheral devices. To prevent this, ad-

just the carrier frequency according to the following standards:

Cable length of 50 meters or less: 10 kHz or less

Cable length of 50 to 100 meters: 5 kHz or less

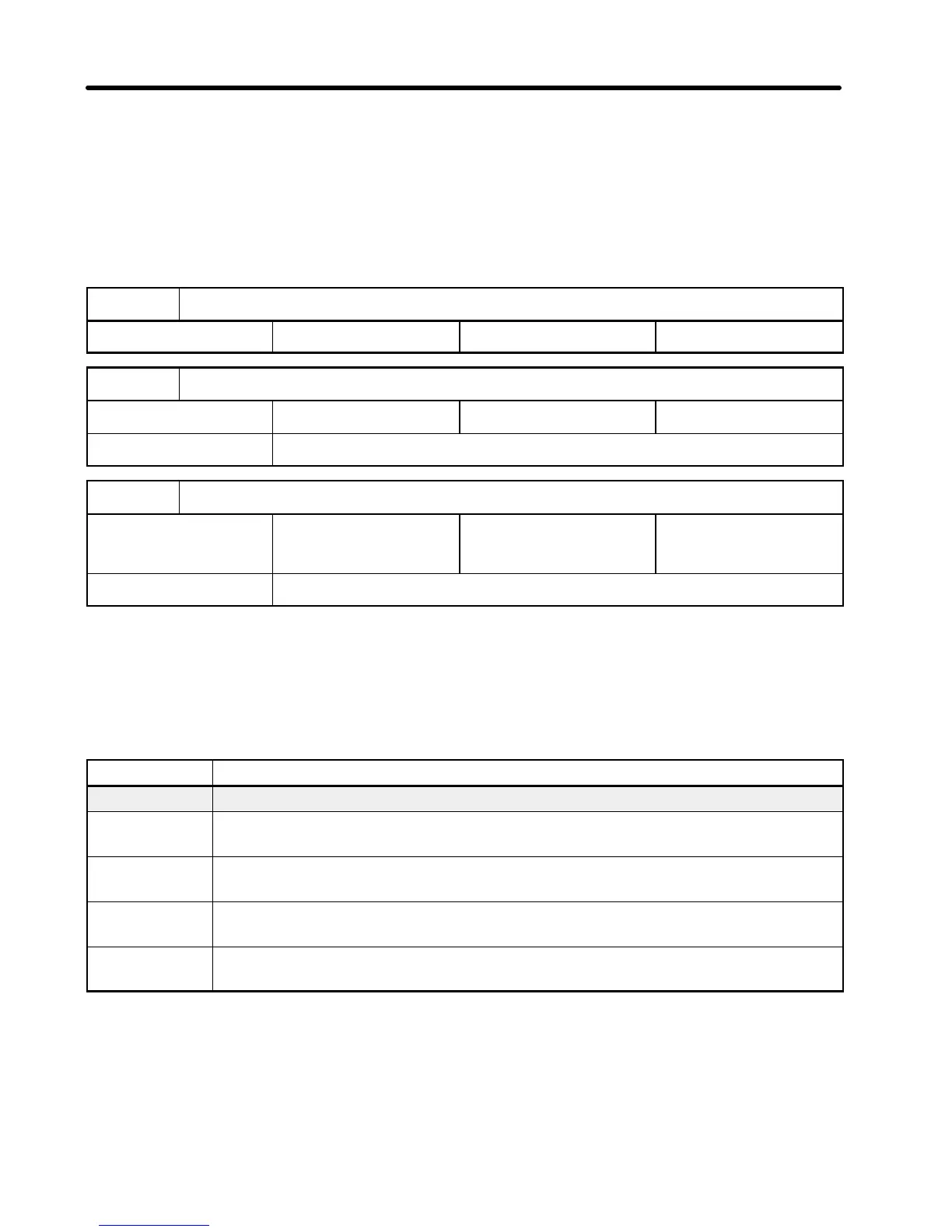

Over-torque Detection Function Selection

Setting range 0to4 Factory setting 0

Over-torque Detection Level

Setting range 30 to 200 (%) Factory setting 160 (%)

Unit of setting 1 (%)

Over-torque Detection Time

Setting range 0.1 to 10

(seconds)

Factory setting 0.1 (seconds)

Unit of setting 0.1 (seconds)

•When excessive load is applied to the equipment, the Inverter detects any increase in

output current and displays the fault according to the n09 and n10 settings (multi-func-

tion output selection).

•n50 is used to specify whether over-torque is to be monitored and specify the action to

be taken when over-torque is detected.

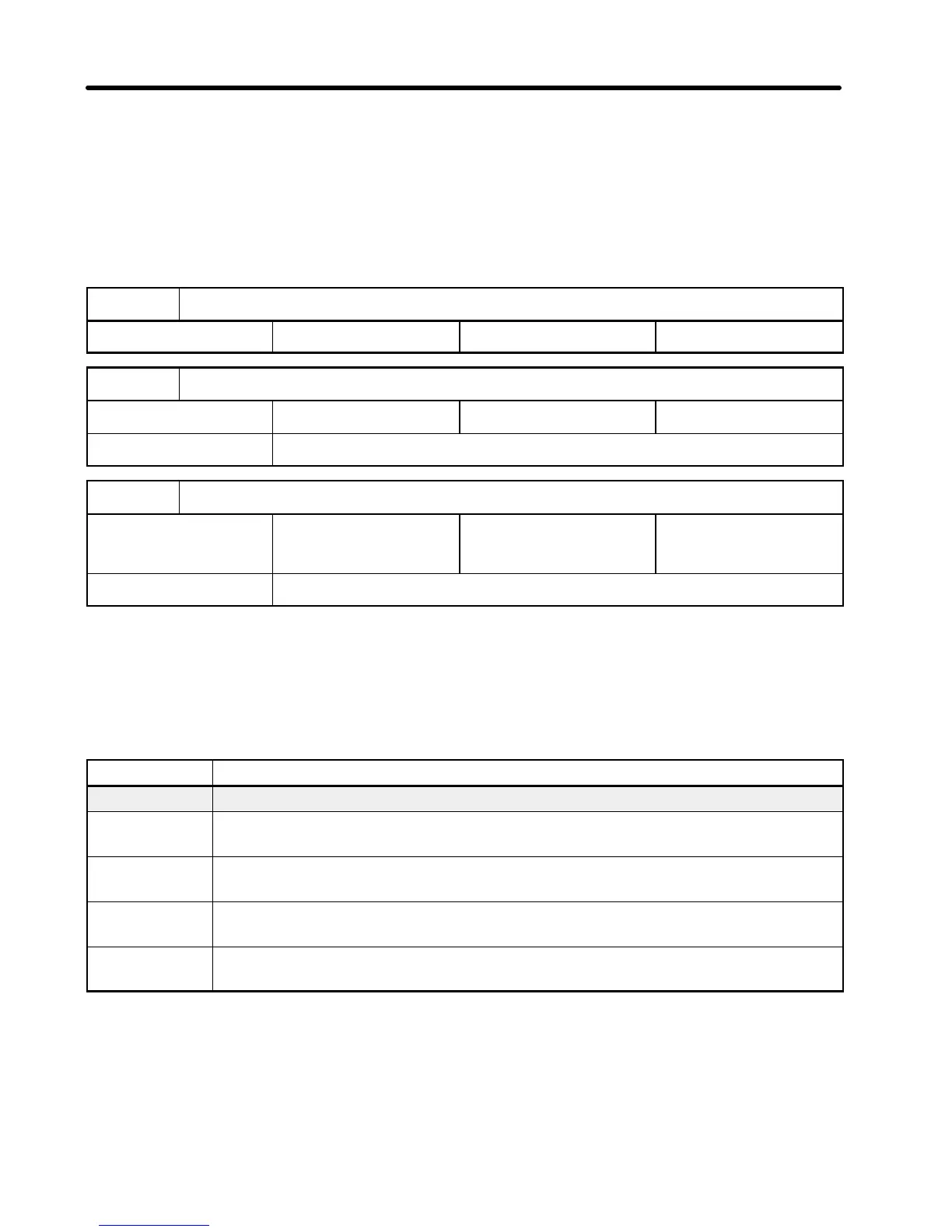

n50 setting Description

0 Inverter does not monitor over-torque.

1 Inverter monitors over-torque only when speed is matched. It continues

operation (issues warning) even after over-torque is detected.

2 Inverter monitors over-torque only when speed is matched. It discontinues

operation (through protection function) when over-torque is detected.

3 Inverter always monitors over-torque during operation. It continues

operation (issues warning) even after over-torque is detected.

4 Inverter always monitors over-torque during operation. It discontinues

operation (through protection function) when over-torque is detected.

•n51 is used to set the over-torque detection level. Specify this value in terms of the

percentage of the rated output current.

•n52 is used to set the over-torque detection time (in seconds).

Chapter 4

Loading...

Loading...