Oneof the following valuescan be specified foreach constant(multi-functionoutput selection):

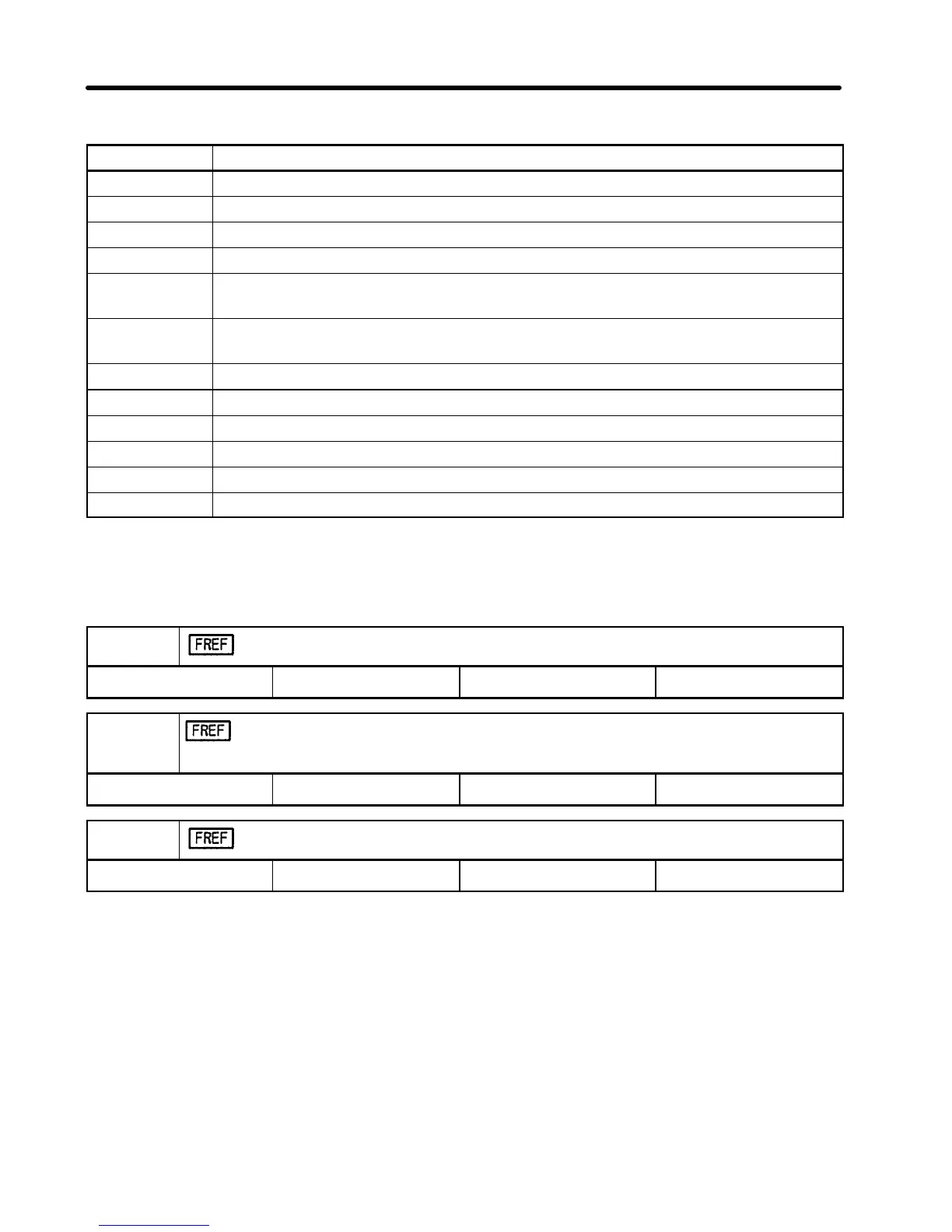

Value Description

0 Fault occurrence (fault occurrence when ON)

1 Operation in progress (frequency reference is being output)

2 Frequency matching (see note)

3 Idling

4 Frequency detection (output frequency ò frequency detection level set in

n53)

5 Frequency detection (output frequency ó frequency detection level set in

n53)

6 Over-torque being monitored

7 Base block in progress

8 Undervoltage(UV) being monitored

9 Speed search in progress

10 Run mode (local when ON, remote when OFF)

11 Normal (abnormal when OFF)

Note The contact is turned on when the difference between the reference frequency

and the output frequency falls within 2 Hz. It is turned off when the difference ex-

ceeds

±

4 Hz.

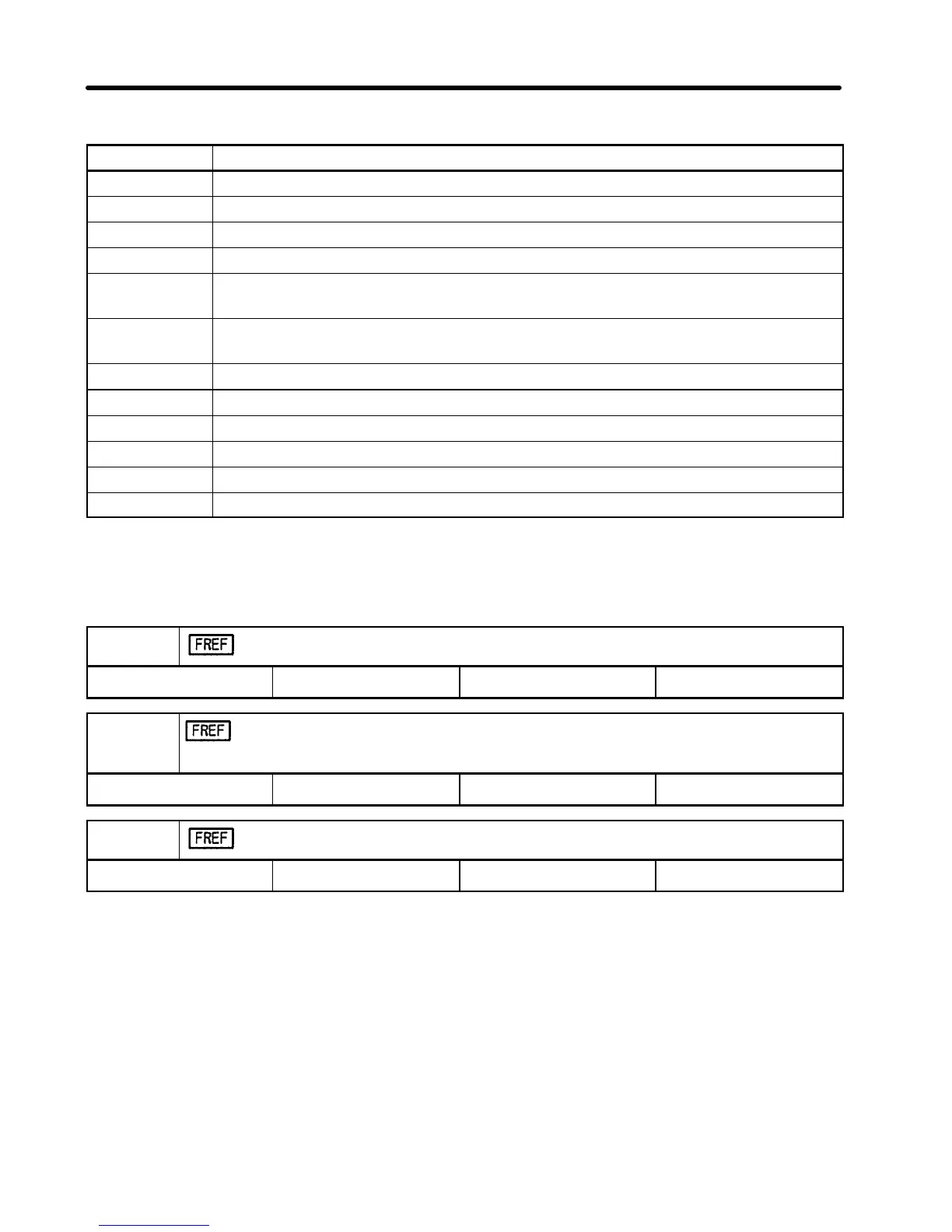

Frequency Reference 1

Setting range 0.0 to 400 (Hz) Factory setting 6.0 (Hz)

to

Frequency References 2 to 7

Setting range 0.0 to 400 (Hz) Factory setting 0.0 (Hz)

Frequency Reference 8

Setting range 0.0 to 400 (Hz) Factory setting 6.0 (Hz)

•

These constants are used to set reference frequency values.

•

The unit of setting is as follows:

0.0 to 99.9 (Hz): 0.1 (Hz)

100 to 400 (Hz): 1 (Hz)

•

The reference frequency value can be changed even during operation. To change the

reference frequency value, light the FREF indicator with the Mode Key first, press the

Increment or Decrement Key to change the value, then press the Enter Key.

•

To change the n12 to n18 settings during operation, select the desired reference fre-

quency with the multi-step speed command, then perform the above operation.

Chapter 4

Loading...

Loading...