Version 1.1.1 - 2021-1-25 37Translation of original instruction

MB4 EN

MB4_GB_5.fm

INFORMATION

The spindle bearing is lifetime-lubricated. It is not necessary to lubricate it again.

Every six

months

Adjustment Z axis

Lubricate

Clamp the milling head.

Remove the service cover from the column.

Lubricate the gearwheels.

When neces-

sary

Spindle nut cross table

Readjusting

Increased gap in the milling table spindles can be reduced by

resetting the spindle nuts. The spindle nuts are reset by reduc-

ing the thread flanks of the spindle nut by means of a take-up

screw. After the reset, it is necessary to check if there is still

smooth movement over the entire path, otherwise wear is con-

siderably increased due to friction between the spindle nut and

the spindle. The regulating screw of the spindle nut of the Y

axis is accessible from the rear side, the regulating screw of

the spindle nut of the x axis is accessible from the right or left

side of the milling table.

When neces-

sary

V-ledges

Readjusting

X and Y axis

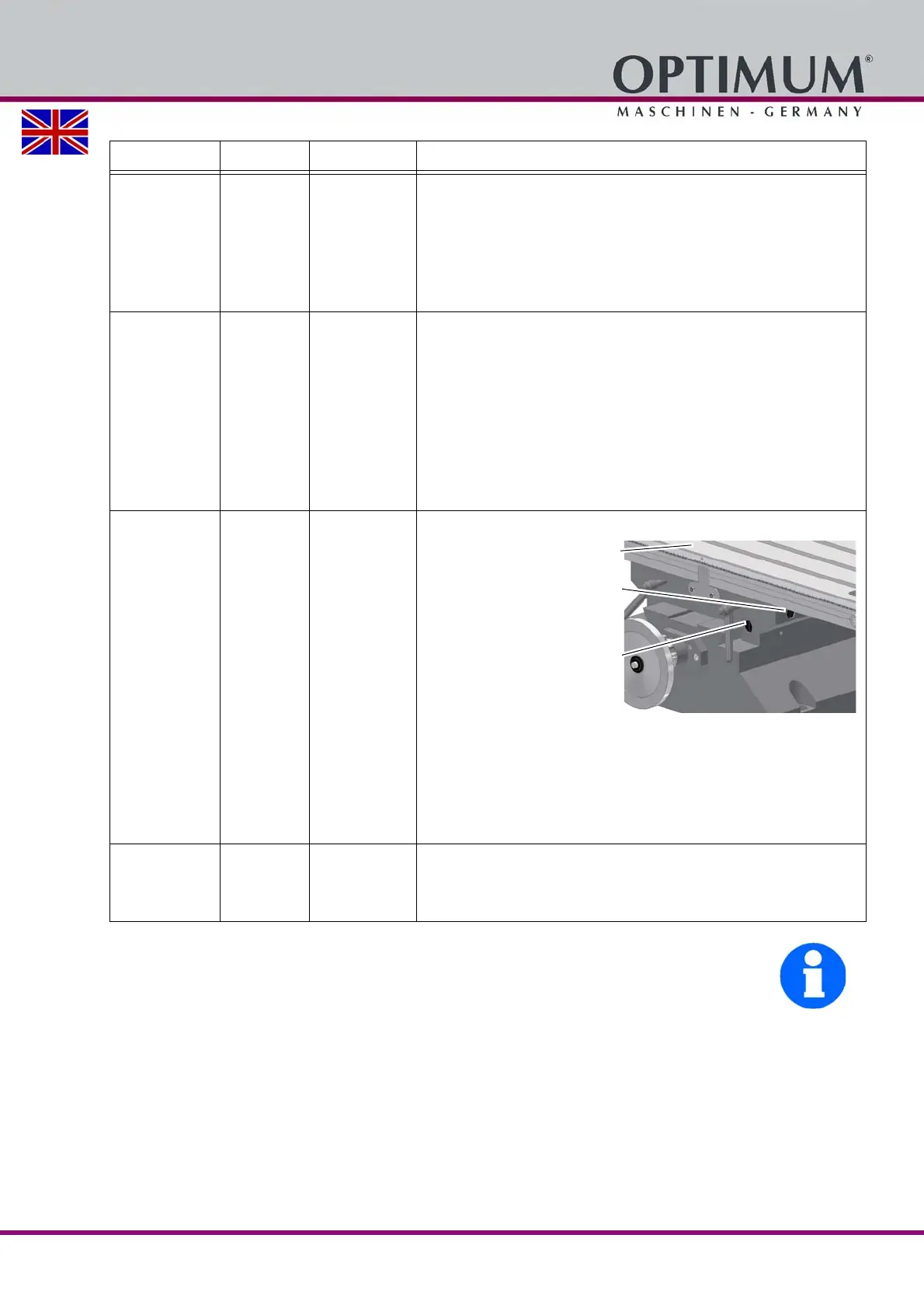

Abb.5-4: Milling table

Turn the adjusting screw of the corresponding V-ledge

clockwise. The V-ledge is pushed further inward thus

reducing the play in the guide rail.

Check the settings. The corresponding guide rail must be

more easily movable but ensure stable guidance.

When neces-

sary

V-ledges

Readjusting

Z axis

Proceed as described under "Readjusting X and Y axis".

Interval Where? What? How?

Milling table

Adjusting screw screw V-ledge

X axis right side

Adjusting screw screw V-ledge

Y axis front

Loading...

Loading...