12

Connection

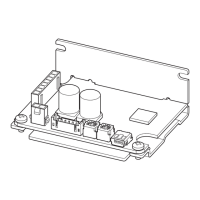

6.3 Connecting the I/O signals (CN2)

Insert the connector of the I/O signal cable into the I/O signal connector (CN2) of the driver.

Lead wire size: AWG26 (0.14 mm

2

)

CN2 pin assignment

Viewed from the direction of an arrow in the right gure

VR2CN2

21

43

65

87

109

1413

1211

Housing: PHDR-14VS (JST)

Terminal: SPHD-001T-P0.5 (JST)

Pin

No.

Lead wire

color

Terminal

name

Initial assignment

signal

*1

Description

14 Yellow/Black DIN0 [START/STOP]

These signals are used to operate the motor.

The motor rotates according to the acceleration time when both the

START/STOP input and the RUN/BRAKE input are turned ON.

If the START/STOP input is turned OFF, the motor stops according to the

deceleration time. If the RUN/BRAKE input is turned OFF, the motor stops

instantaneously.

13

Orange/

White

DIN1 [RUN/BRAKE]

12 Red/White DIN2 [FWD/REV]

This signal is used to change the motor rotation direction.

The motor rotates in the forward direction when the signal is turned ON.

*2

11 Brown/White DIN3 [M0]

The operation data number can be selected based on a combination of

ON-OFF status of the M0 and M1 inputs.

10 Black DIN4 [M1]

9 White DIN5 [ALM-RST]

This signal is used to reset the alarm.

(The alarm will be reset at the ON edge of the input.)

8 Gray VH

External analog

setting device

*3

These terminals are used when the rotation speed or torque limiting

value is externally set using an external analog setting device (external

potentiometer or external DC voltage).

7 Purple VM

6 Blue VL

5 Green GND GND I/O signals common

4 Yellow DOUT0 [SPEED-OUT] 30 pulses are output while the motor output shaft makes one revolution.

3 Orange DOUT1 [ALM-B]

This is a signal to output an alarm status.

It is turned OFF when an alarm is generated. (Normally closed)

2 Red DOUT2 [TLC] This is a signal to output when the motor output torque is limited.

*4

1 Brown DOUT3 [DIR]

This is a signal to output information of the motor rotation direction.

(It is turned ON when the motor rotates in the forward direction.)

*1

A signal assigned at the time of shipment is described in brackets [ ]. Functions for the pin No.1 to No.4 and No.9 to No.14

can be changed using the MEXE02.

*2

The rotation direction of the output shaft varies depending on the gear ratio of the gearhead.

The rotation direction can be changed by setting of the "Motor rotation direction" parameter.

*3

If the "External setting method" parameter is changed, the rotation speed and torque limiting value can be set with the

PWM signal input.

*4

The torque limiting value is set to 200% at the time of shipment and can be changed using the MEXE02.

Loading...

Loading...