Positioning operation

−122−

6 Operation in position control mode

•

Notes about sequential positioning operation

If the following operations are performed while sequential positioning operation is executed, the starting point of the

sequential positioning operation will be changed to the operation No.0.

And the present operation data number will be set to "

–

1."

•

When the power supply was turned on

•

When any of operations other than positioning operation was executed

•

When an alarm was generated and reset

•

When the BRAKE (STOP) input was turned ON

•

When a command to turn o the motor excitation, such as the FREE input or S-ON input, was input

•

When the position preset was executed

Note

When sequential positioning operation of the operation data which "Operation function" is set to "Linked-

motion" or "Linked-motion 2” is performed, set the "Sequential positioning" to "Enable."

2.3 Operation function

Single-motion operation

Positioning operation is executed only once using a single operation data set.

•

Example of single-motion operation

Operation

data

Position

Operating

speed

Operation

mode

Operation

function

Acceleration

time

Deceleration

time

Torque limit

No.1 5000 1000 INC Single-motion 1.000 1.000 250

Operation image

Speed

Operating speed of data No

.1: 1000

Operation data

No.1

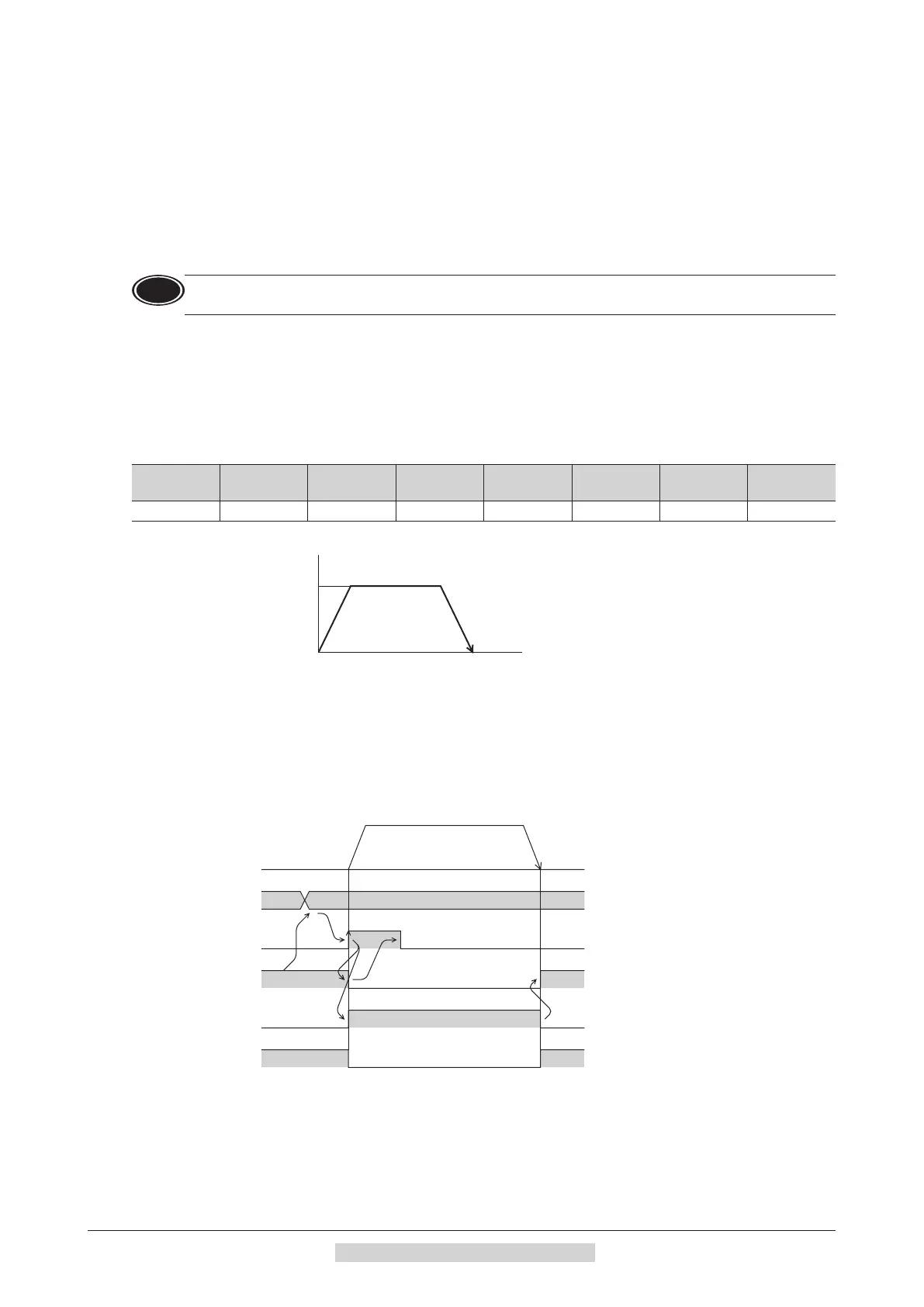

Operating method

1) Check the READY output is being ON.

2) Turn the M0 input ON to select the operation data No.1, and turn the START input ON.

3) The motor starts positioning operation of the operation data No.1.

4) Check the READY output has been turned OFF and turn the START input OFF.

5) When the positioning operation is completed, the READY output is turned ON.

①

②

⑤

④

START input∗

MOVE output

END output

READY output

Motor movement

∗ No.0 No.1

No.1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

③

*

After setting the M0 to M3 inputs, wait at least 10 ms before turning the START input ON.

Loading...

Loading...