Made in the U.S.A.

FIELD SETTINGS

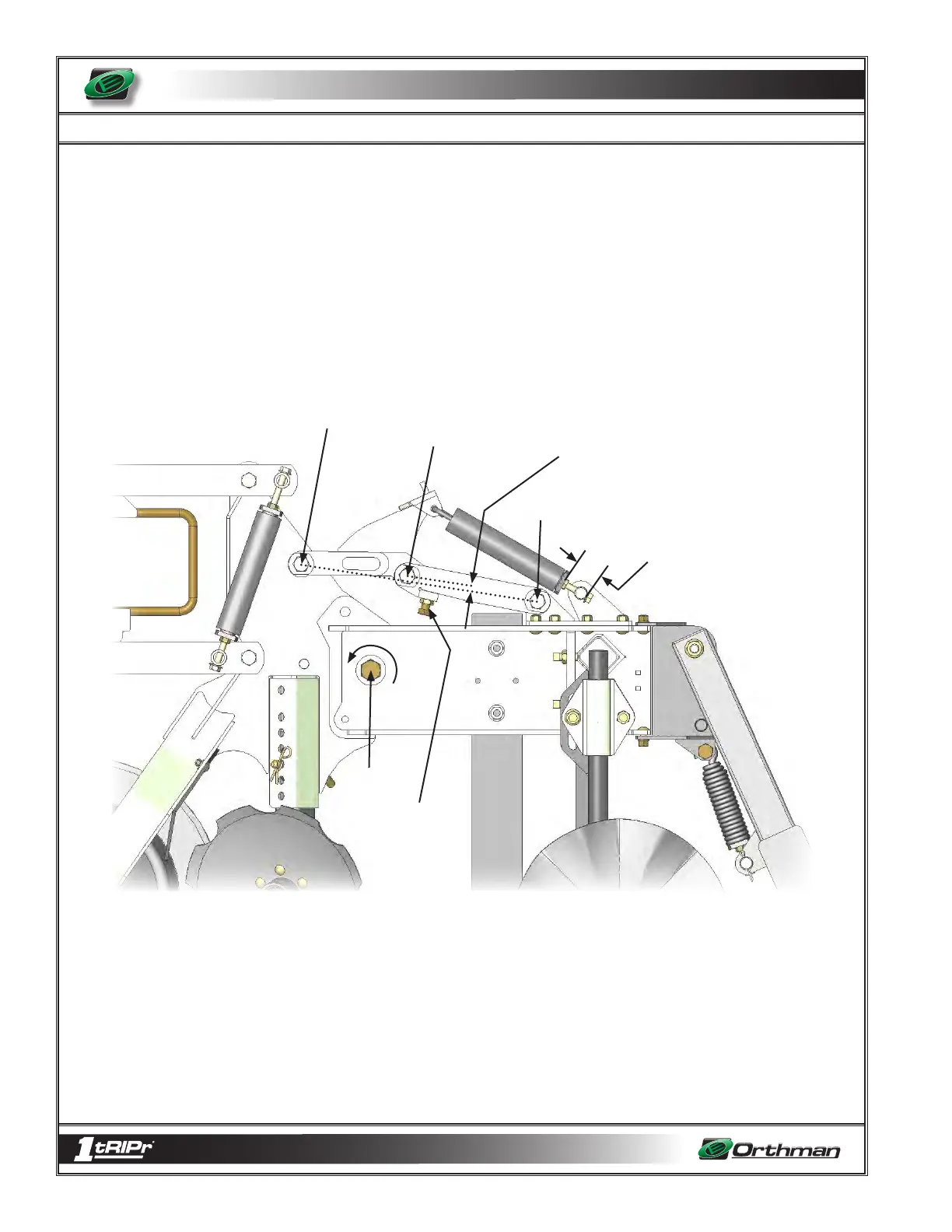

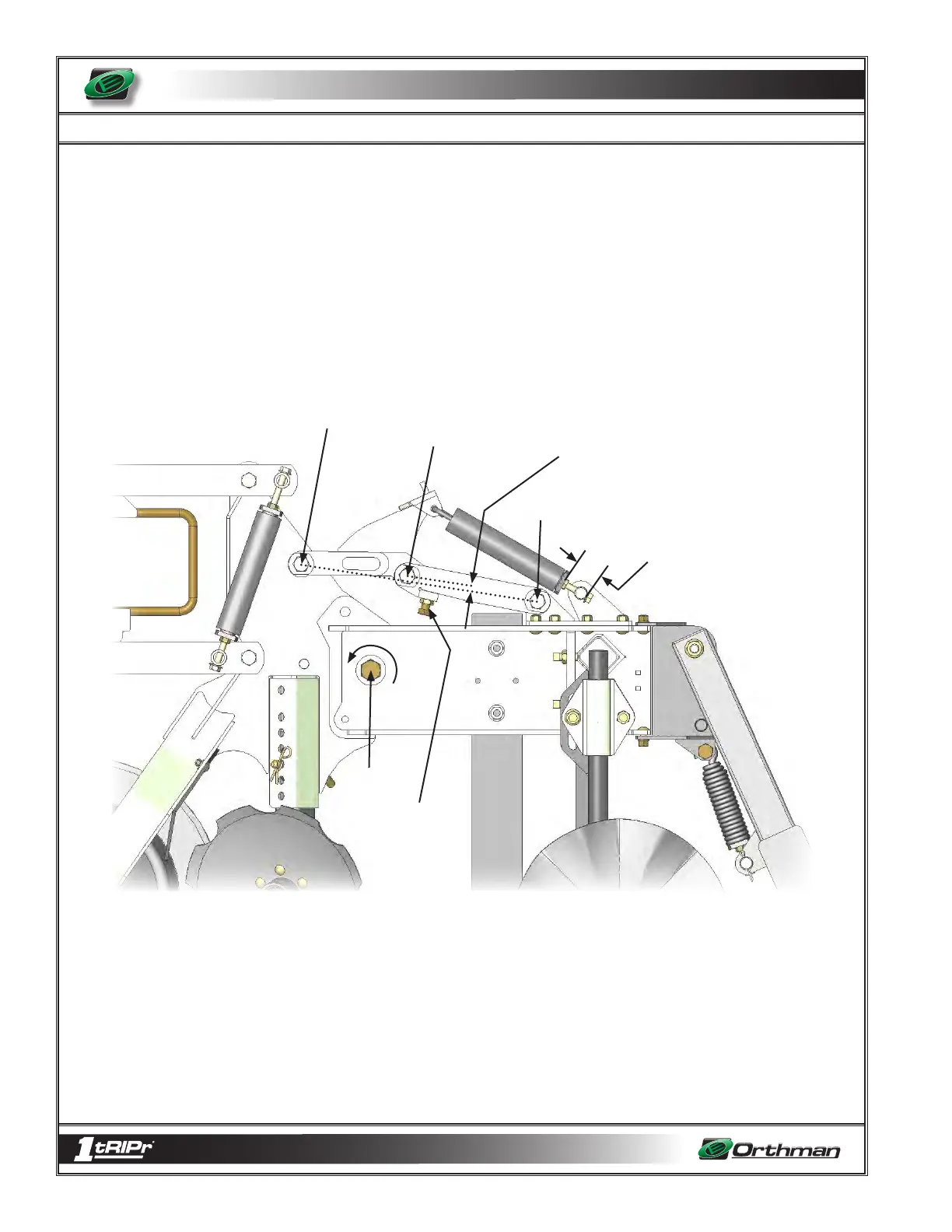

The AR Linkage comes set from the factory to trip easily, and will need adjusted to adapt

to your specific operating conditions. It is important that the user understand how the AR

Linkage works and the results of the different adjustments. The image below identifies

the important geometry points and adjustment locations. Without the AR Linkage, the tail

would be free to rotate about point “D”. The Linkage installed keeps the tail from rotating

about point “D” by creating a brace between points “A” and “B”. That brace is made of two

links and has the ability to buckle in the middle at point “C”. When the shank encounters

an immovable object, the resulting force will buckle the linkage at point “C” allowing the

tail to rotate upward about point “D” until the obstacle is cleared. The upward rota-

tion of the tail, and the buckling of the linkage causes the four reset springs to become

stretched. The spring force stored in the stretched springs provides the power necessary

to rotate the tail downward, which in turn drives the shank back into the ground and snaps

the linkage back into place.

If you visualize a straight line between points “A” and point “B”, the distance point “C” is

away from that straight line directly effects how difficult it is to buckle the trip linkage.

The closer point “C” is to that line the more difficult it is to trip. The further away point “C”

is from that line the easier it is to trip. Our factory setting from Orthman Mfg. puts this

point “C” further from that line so it trips easily. Our factory setting (or distance “X” is ¾”)

Operators are encouraged to adjust this setting by loosening the jam nut under point “C”

and adjusting the set bolt. (with 15/16 wrenches) One full turn of this set bolt represents

about 1/8”. It may only be necessary to move the set bolt ¼ to ½ a turn to achieve the

correct offset distance for your soil and desired tripping operation.

Point A

Distance “X”

(Distance Point C is away from a

straight line from A to B)

Point B

Point C

Sprint tension

distance setting

“Y”

Adjustable

Screw for

setting “X”

Point

D

5 - 18

Loading...

Loading...