Operation

18

DTX-2200-3000 AC/DC

14 Operation

14.1 TIG-welding

In the TIG process welding is achieved by melting the two metal pieces to be joined, with the possible addition of

material from the outside, using an arc ignited by a tungsten electrode. The molten bath and the electrode are

protected by and inert gas (e.g. Argon, and a flow rate of around 8-14 litres per minute). If necessary, to complete

the welded joint, suitable additional material is added.

This type of welding is used to weld thin sheet metal or when elevated quality is required.

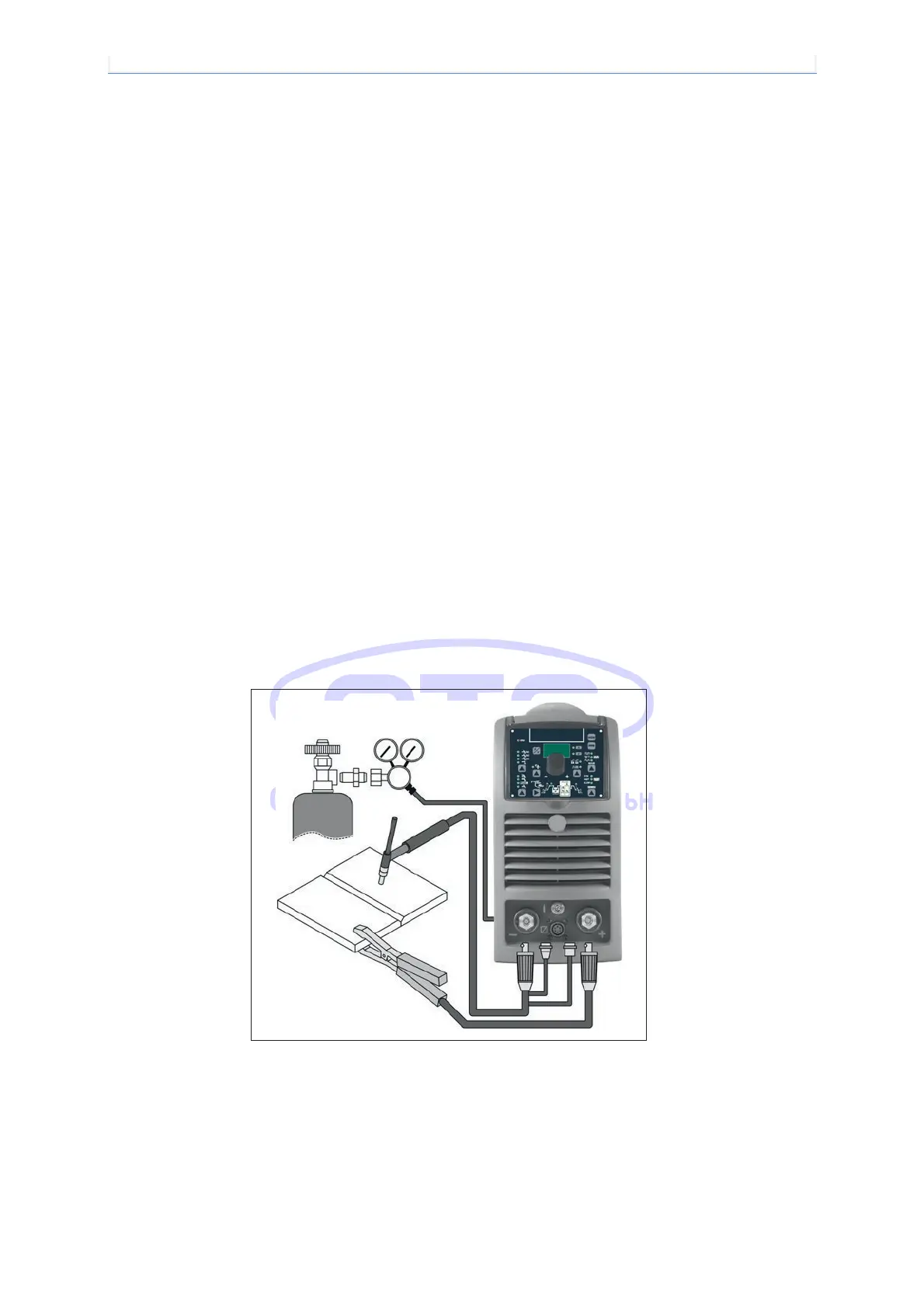

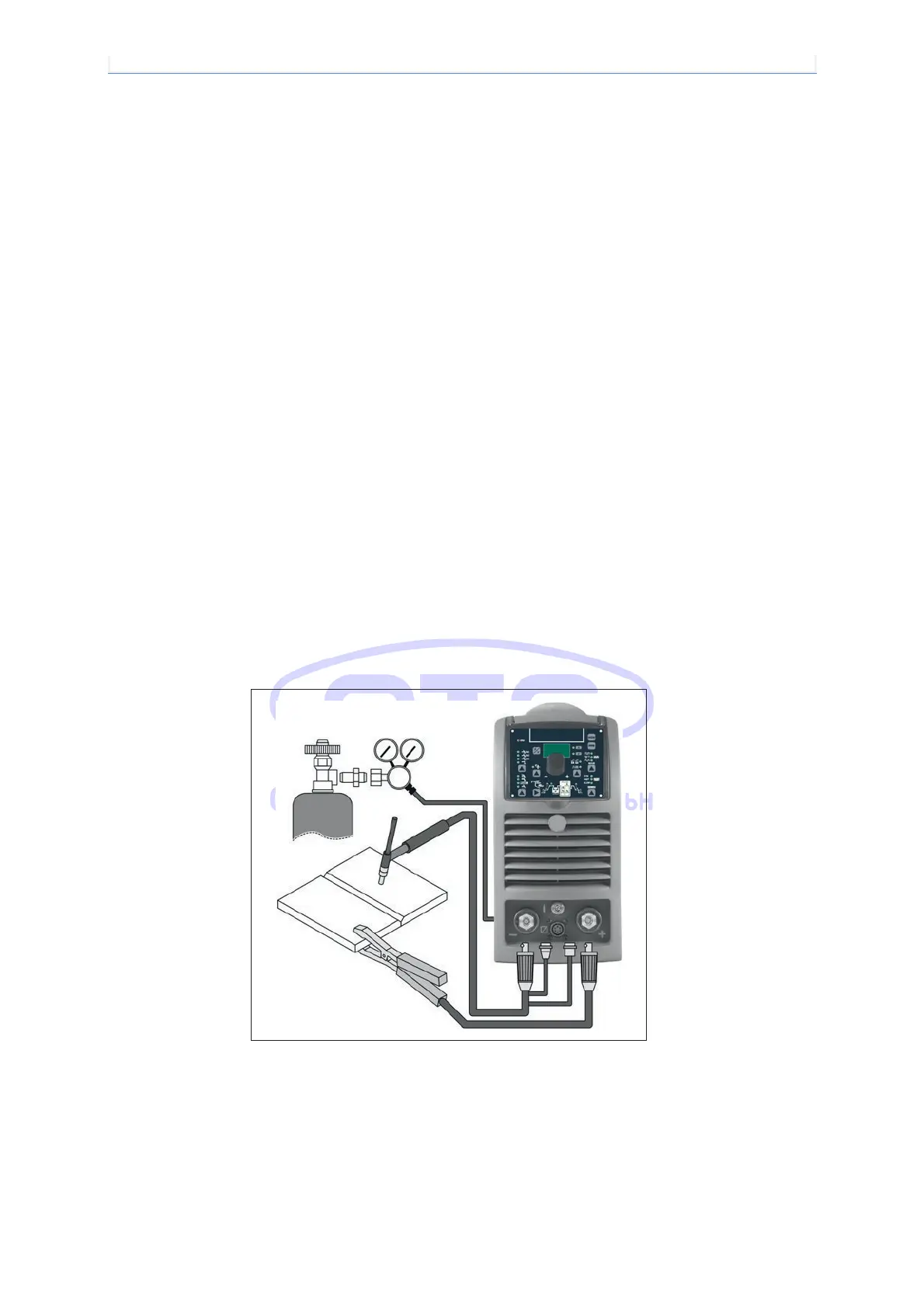

1) Connecting the welding cables (Image 2):

• Connect the gas hose to the Argon cylinder.

• With the machine switched off:

- Connect the ground cable to the snap on connector marked + (positive).

- Connect the relative ground clamp to the work piece or to the work piece support in an area free of rust,

paint, grease, etc..

- Connect the TIG torch power cable to the snap on connector marked - (negative).

- Connect the torch gas tube to the connection (Pos. 3, Image 1).

- Insert the torch button connector in the 6 poles holder (Pos. 4, Image 1).

2) Switch the welding machine on by moving the power supply switch to I (Pos. 6, Image 1).

3) Make the adjustments and select the parameters on the control panel (for further information see chapter

14.3).

Image 2

Loading...

Loading...