Operation

22

DTX-2200-3000 AC/DC

14.2.2 Welding Parameters

Table 4 shows some general indications for the choice of electrode, based on the thickness of the parts to be

welded. The values of current to use are shown in table 5 with the respective electrodes for the welding of

common steels and low-grade alloys. These data have no absolute value and are indicative data only. For a

precise choice follow the instructions provided by the electrode manufacturer.

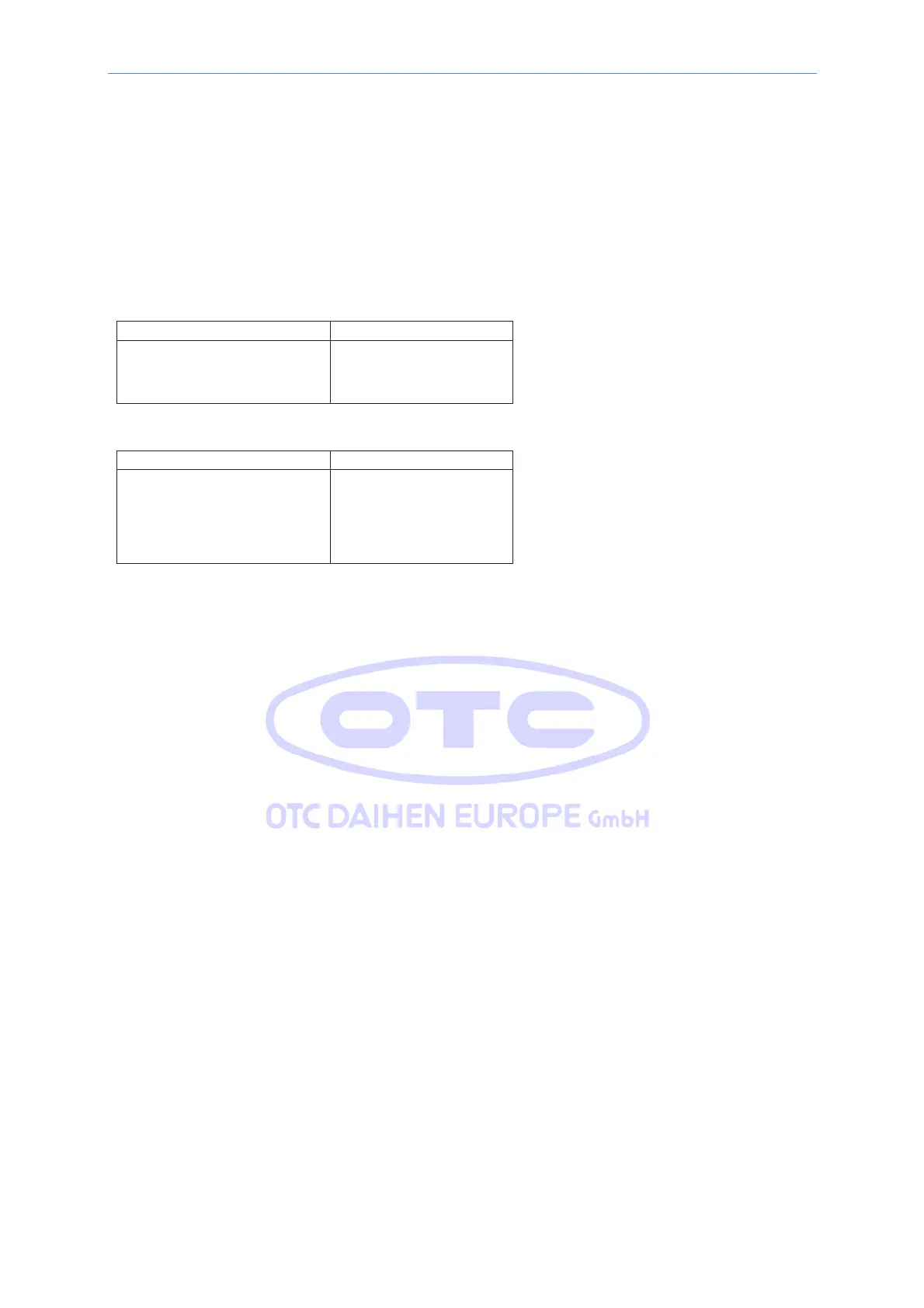

Table 4

WELDING THICKNESS

(mm)

Ø ELECTRODE

(mm)

1,5 - 3

3 - 5

5 - 12

≥ 12

2

2,5

3,2

4

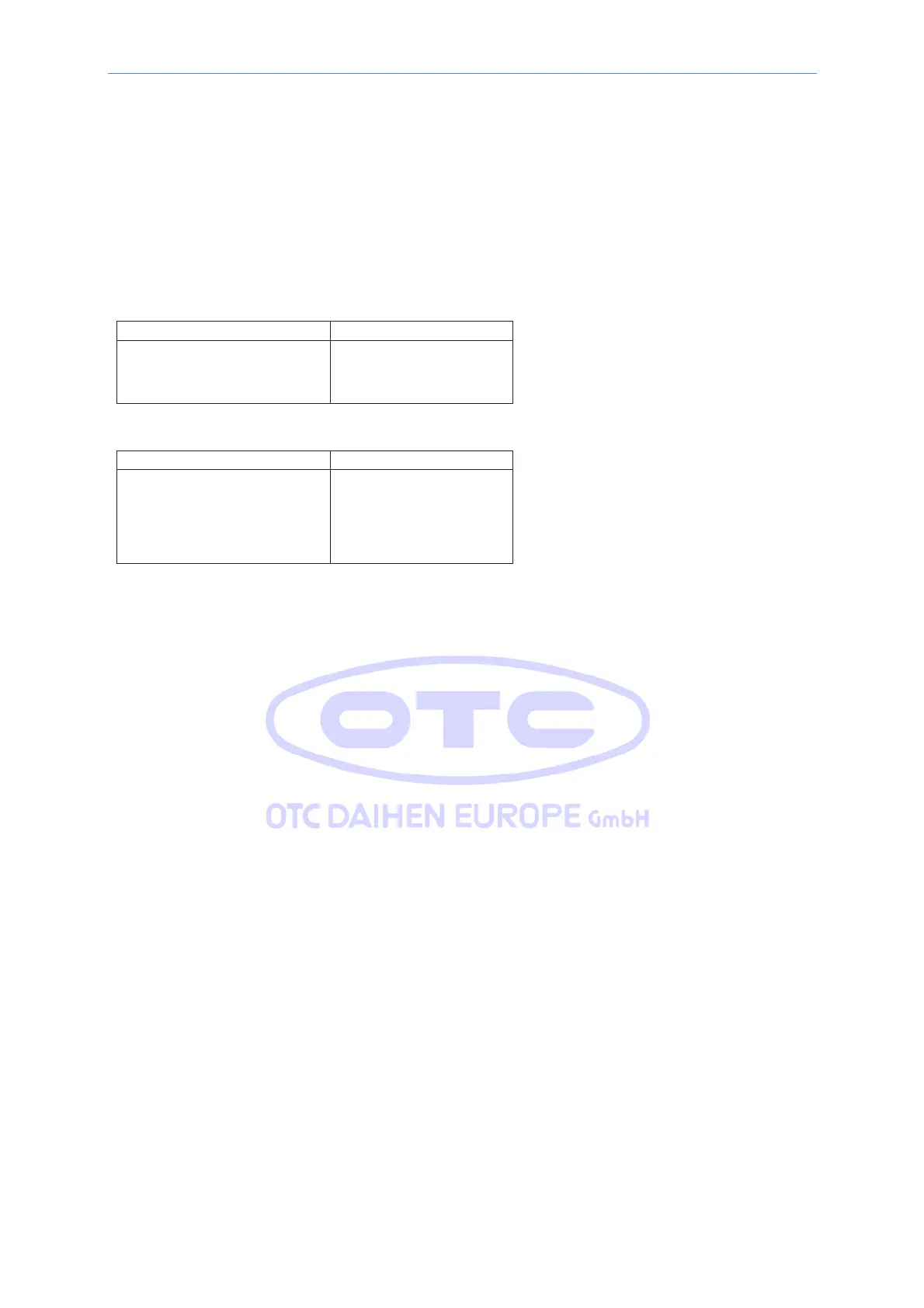

Table 5

Ø ELECTRODE

(mm)

CURRENT

(A)

1,6

2

2,5

3,2

4

5

30 - 60

40 - 75

60 - 110

95 - 140

140 - 190

190 - 240

The current to be used depends on the welding positions and the type of joint, and it increases

according to the thickness and dimensions of the part.

The current intensity to be used for the different types of welding, within the field of regulation shown in

table 5 is:

• High for plane, frontal plane and vertical upwards welding.

• Medium for overhead welding.

• Low for vertical downwards welding and for joining small preheated pieces.

A fairly approximate indication of the average current to use in the welding of electrodes for ordinary steel is

given by the following formula:

I = 50 × (Øe - 1)

Where:

I = intensity of the welding current

Øe = electrode diameter

Example:

For electrode diameter 4 mm

Beispiel: Elektrodendurchmesser 4 mm

I = 50 × (4 - 1) = 50 × 3 = 150A

Loading...

Loading...