Operation

37

DTX-2200-3000 AC/DC

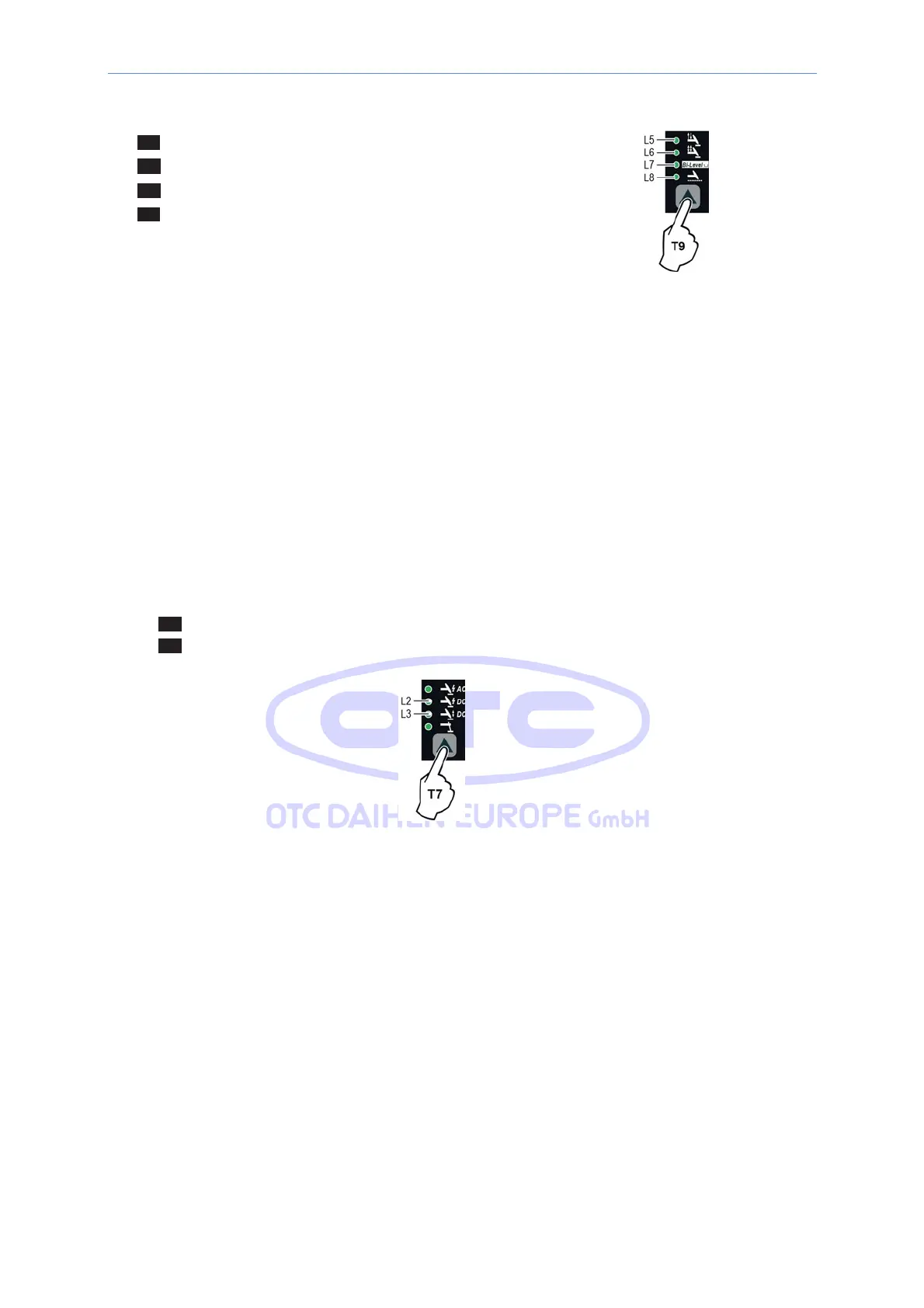

7) Press the WELDING MODE SELECTION Key (T9) and go to one of the 4 options available:

L5 2T

L6 4T

L7 Bi-Level

L8 SPOT WELD

8) By pushing the WELDING PARAMETERS SELECTION key a number of times it is possible to

set the various TIG WELDING PARAMETERS (see the “TIG AC and DC Welding” paragraph -

WELDING PARAMETERS).

9) Once the all the

selections/regulations

indicated

above have been made, welding can begin.

10)

During

the

welding process

the

DISPLAY shows

the

real

Amps (A) at which the operator is actually welding.

14.3.5

TIG „DC“ -welding

1) Start the welding machine by turning the power supply switch to position I.

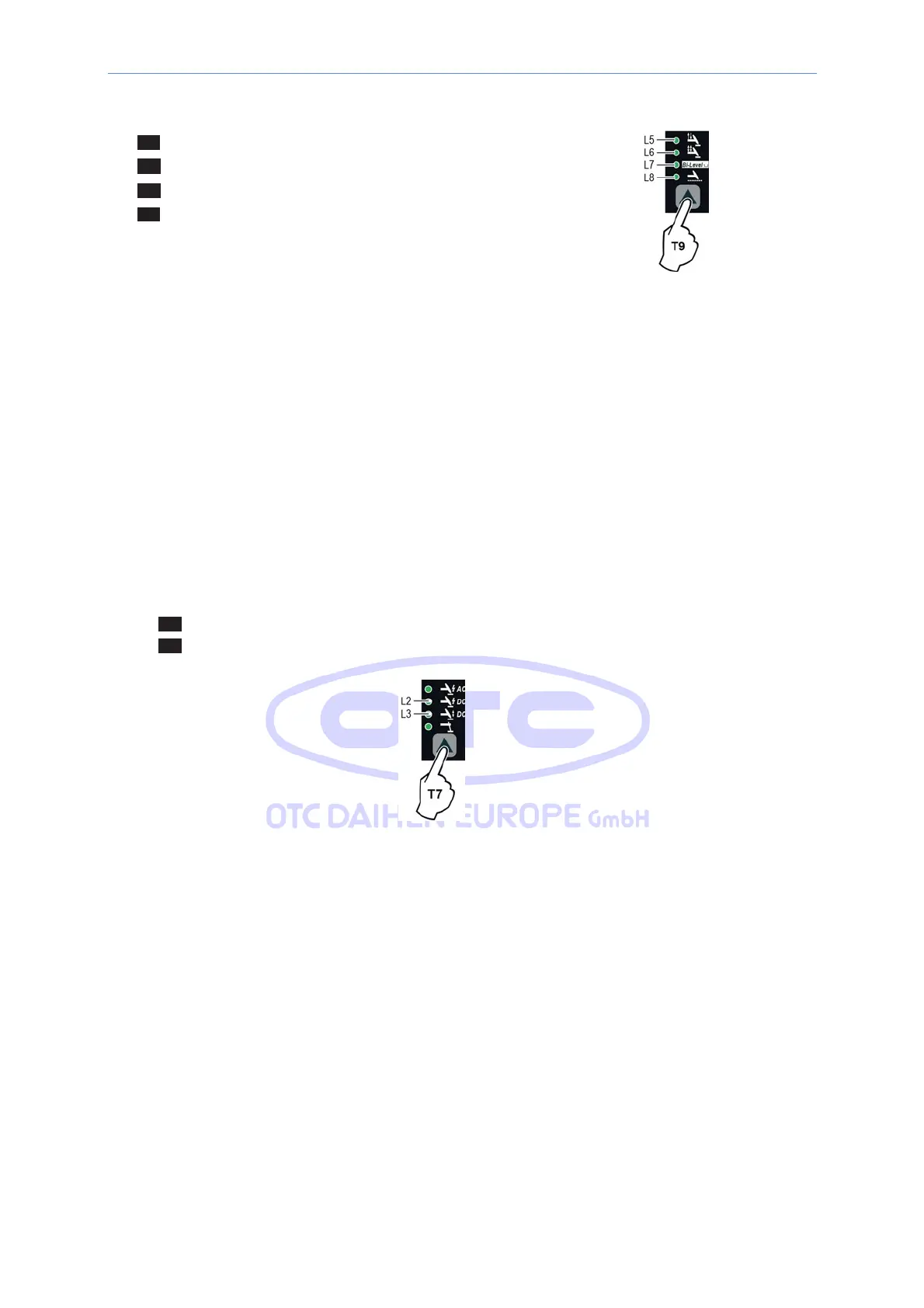

2) Press the WELDING PROCESS SELECTION key (T7) and select:

L1 a TIG “HF” welding process for direct current TIG welding with high frequency ignition.

L2 a TIG “Lift DC” welding process for direct current TIG “Lift” type welding without high frequency.

WARNING: The “Lift” ignition current is created by pushing the torch button only after having touched the

work piece with the electrode.

3) ELECTRODE DIAMETER

SELECTION

Select the diameter of the electrode to achieve the best control of ignition in a synergic

manner.

Selection

is done by pushing the ELECTRODE DIAMETER Key (T8) (ELECTRODE

DIAMETER LED flashing) and using the EN- CODER Knob (E) to regulate the value indicated on

the DIS- PLAY (D).

Loading...

Loading...