Operation

20

DTX-2200-3000 AC/DC

14.1.1 Part to be welded

The part to be welded must always be connected to ground in order to reduce electromagnetic emission. Much

attention must be afforded so that the ground connection of the part to be welded does not increase the risk of

accident to the user or the risk of damage to other electric equipment. When it is necessary to connect the part to

be welded to ground, you should make a direct connection between the part and the ground shaft. In those

countries in which such a connection is not allowed, connect the part to be welded to ground using suitable

capacitors, in compliance with the national regulations.

14.1.2 Welding Parameters

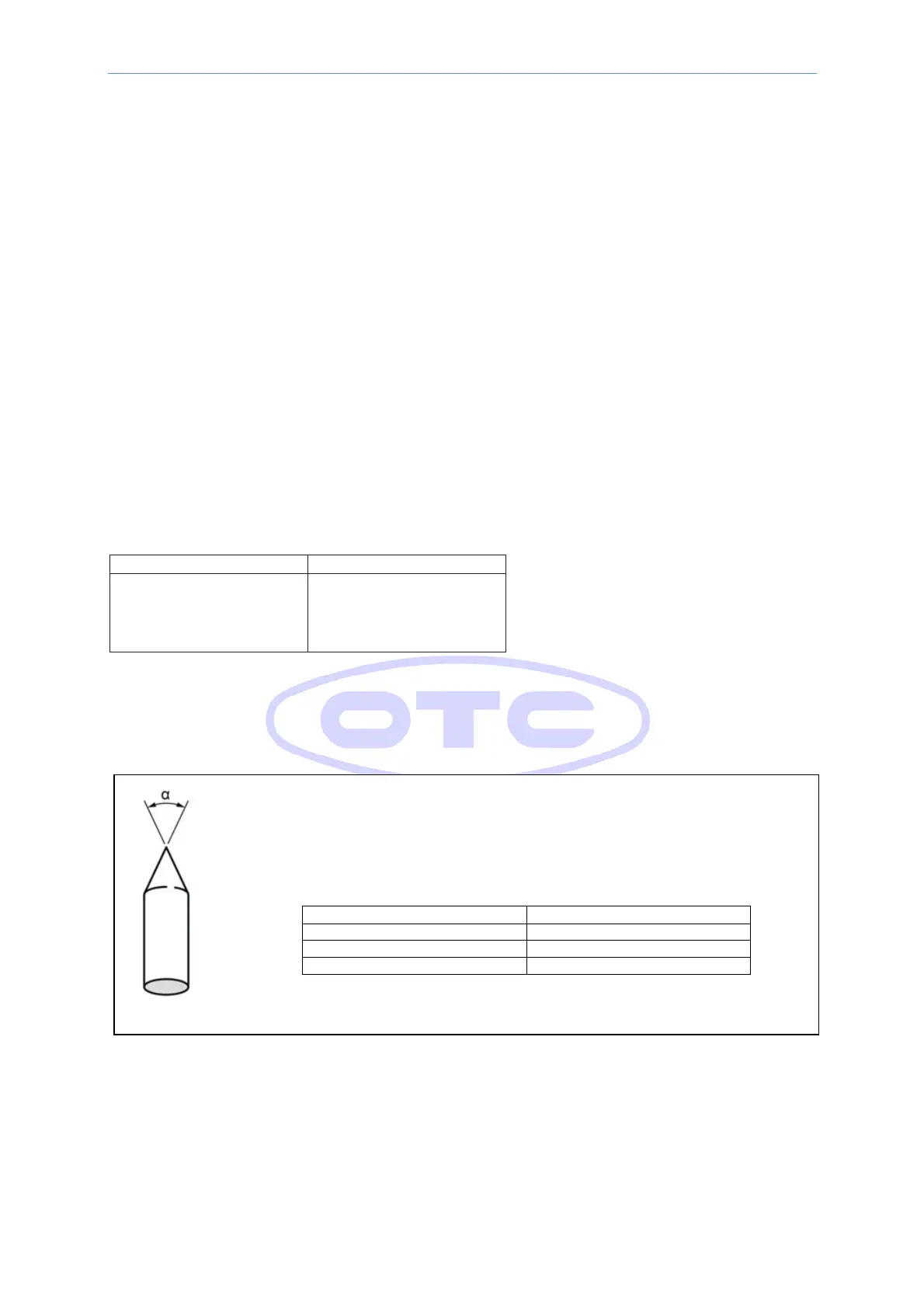

Table 3 shows the currents to use with the respective electrodes for TIG welding. This input is not absolute but is

for your guidance only; read the electrode manufacturers’ instructions for a specific choice. The diameter of the

electrode to use is directly proportional to the current being used for welding.

Table 3

Before use, sharpen the tungsten electrode, forming a tip about 1,5 times its diameter.

Ø ELECTRODE

(mm)

CURRENT

(A)

1,2

1,6

2,4

3,2

4,0

10 - 80

70 - 150

140 - 250

225 - 400

300 - 500

Image 5

If the electrode comes into contact with the work piece, the point must be formed

again

The point on the electrode must be shaped

as

shown in the figure.

(°)

Strom (A)

30 0 - 30

60 - 90 30 - 120

90 - 120 120 -150

Loading...

Loading...