Operation

31

DTX-2200-3000 AC/DC

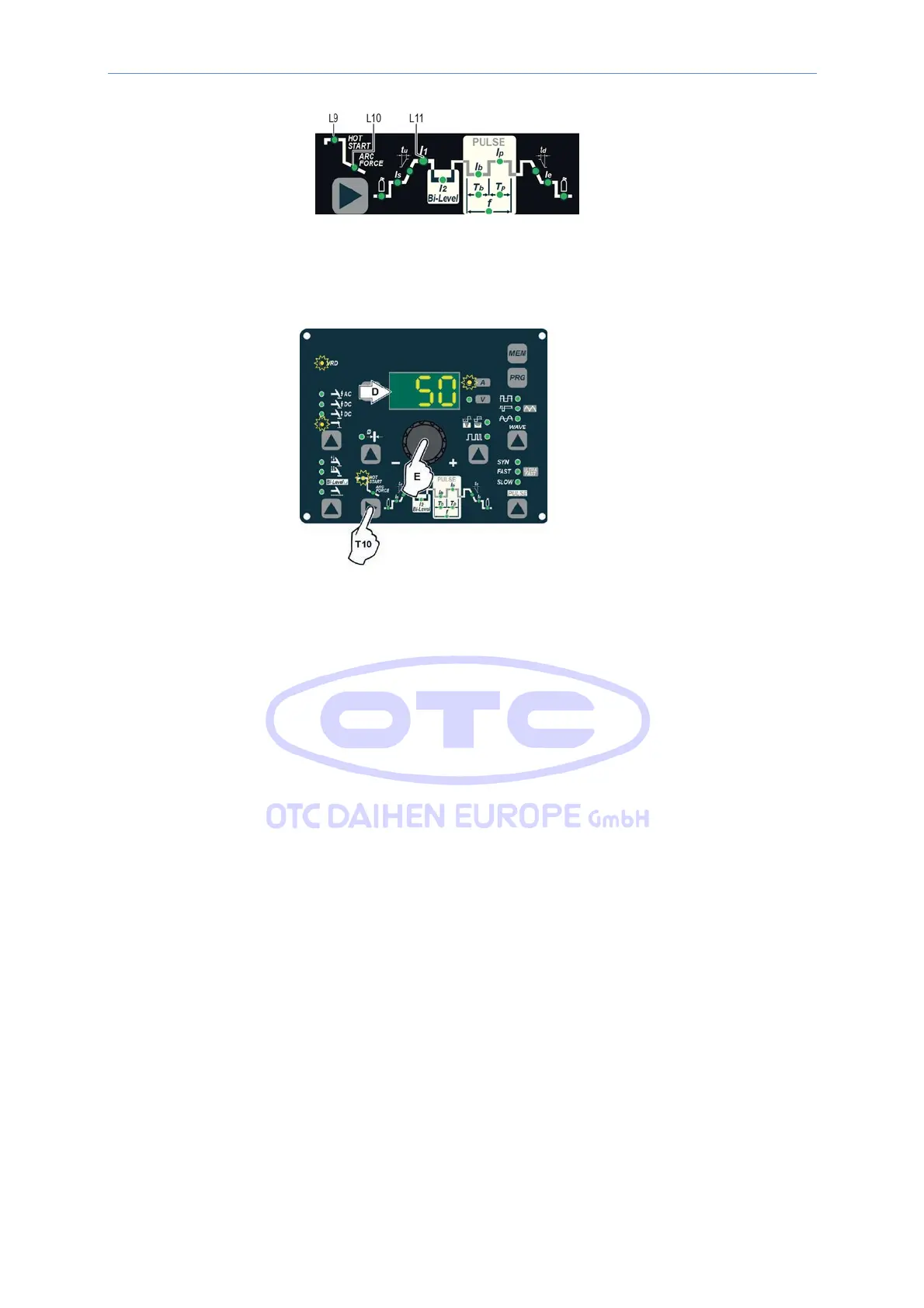

The value for the welding parameters can be regulated using the ENCODER knob (E).

5) To exit these functions hold the WELDING PARAMETERS SELECTION key (T10) down for about 1

second, after which the DISPLAY INDICATION LED switches on and the welding machine is once

again ready to weld at the current indicated on the DISPLAY (D).

6) Once the all the selections/regulations indicated above have been made, welding can begin.

7) During the welding process the DISPLAY (D) shows the real Amps (A) at which the operator is actually

welding.

14.3.4 TIG “AC” welding

1) Start the welding machine by turning the power supply switch to position I.

2) Push the WELDING PROCESS SELECTION key (T7) to select the TIG “HF AC” welding processes for TIG

welding in alternating current with high frequency (HF) ignition.

3) ELECTRODE DIAMETER

SELECTION

Select

the

diameter

of the

electrode

to

achieve

the best control of ignition in a synergic manner. Selection is done

by pushing the

ELECTRODE

DIAMETER Key (T8)

(ELECTRODE

DIAM- ETER LED flashing) and using the

ENCODER Knob (E)

to

regulate the value indicated on the DISPLAY (D).

Loading...

Loading...