Operation

39

DTX-2200-3000 AC/DC

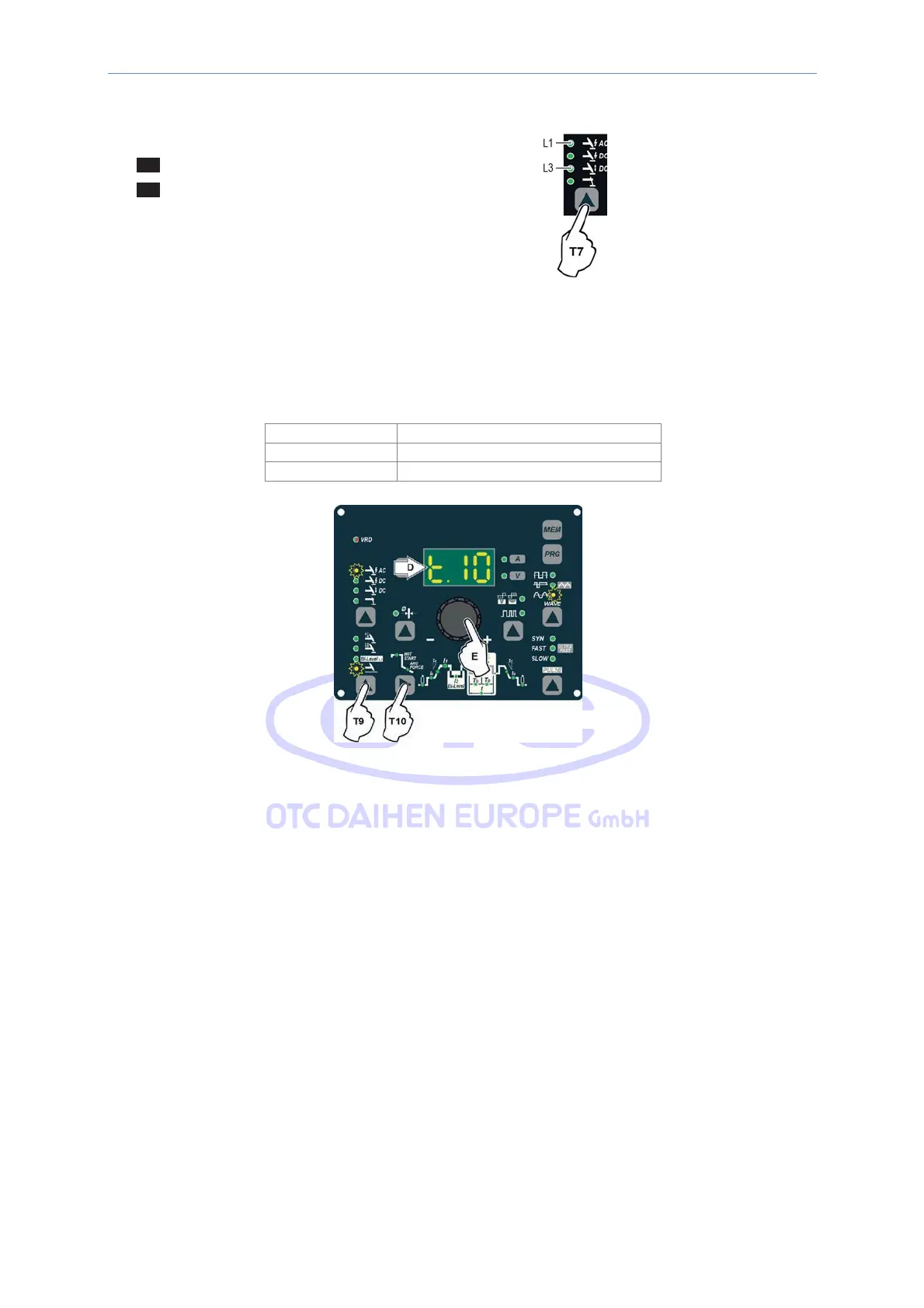

2) Press the WELDING PROCESS SELECTION Key (T7) and select one of the welding machine’s 2 TIG

processes:

L1 TIG “HF AC”

L3 TIG “Lift DC”

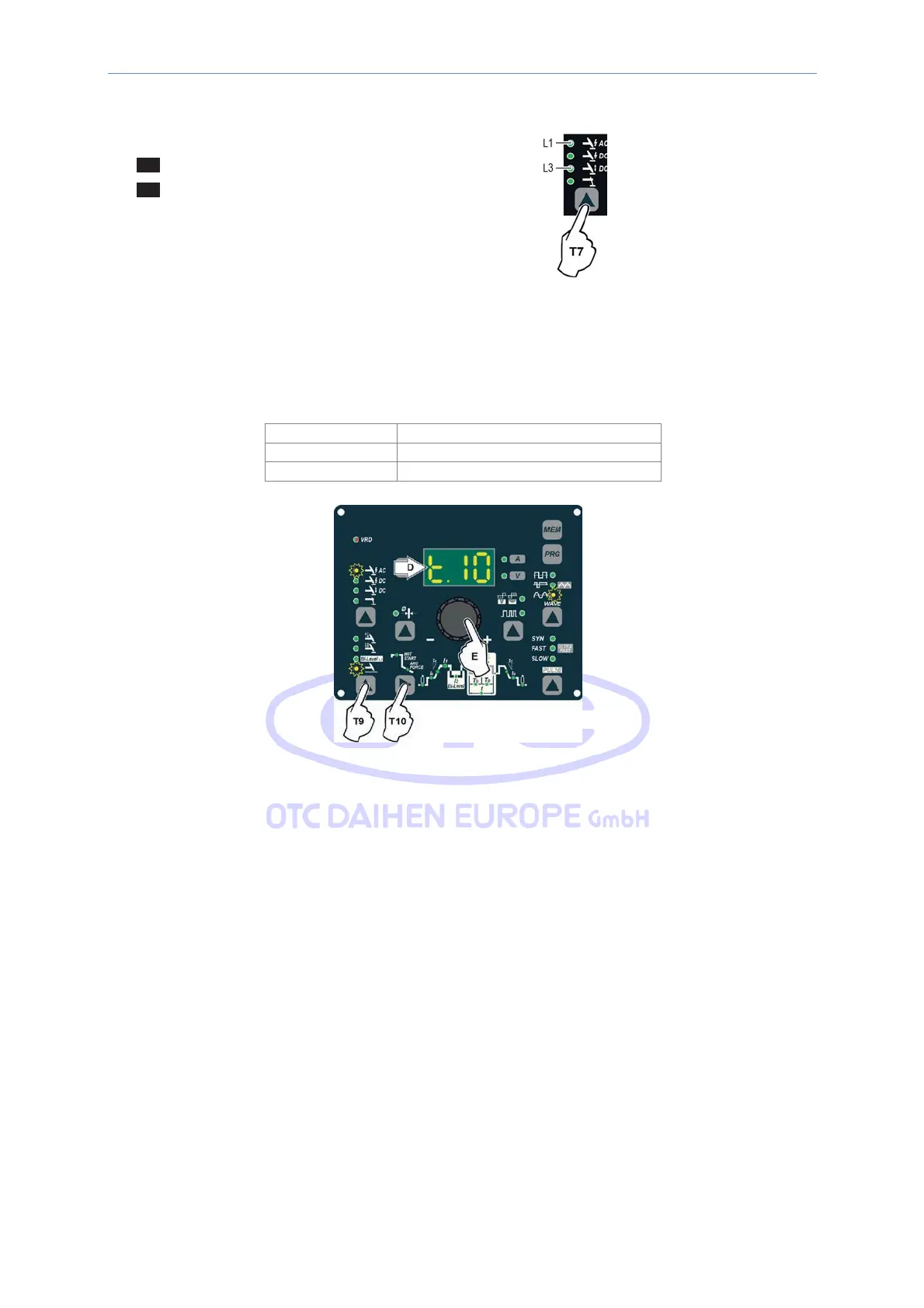

3) Press the WELDING MODE SELECTION Key (T9) and go to one of the SPOT WELDING function.

4) Press and release the WELDING PARAMETERS SELECTION Key (T10) until the SPOT WELD LED starts

flashing.

5) Rotate the ENCODER knob (E) to set the SPOT WELDING time required.

2200 AC/DC - 3000 AC/DC

TIG

AC

0,1 - 10,0 sec

TIG LIFT DC 0,01 - 10,0 sec

6) By pushing the WELDING PARAMETERS SELECTION (T10) key a number of times it is possible to set the

various TIG WELDING PARAMETERS (see the “TIG AC and DC Welding” paragraph - WELDING

PARAMETERS).

7) Hold the SELECT WELDING PARAMETERS (T10) key down to save the parameters chosen.

8) Once the all the selections/regulations indicated above have been made, welding can begin.

9) During the welding process the DISPLAY shows the real Amps (A) at which the operator is actually welding.

14.3.7

TIG HF DC welding with TACK function active and single

ColdTack point

Innovative TIG HF DC tack weld device that makes it possible to do precise, safe tack welding with very little heat

applied. Thanks to the “Perfect-Point” mode, ColdTack guarantees perfect centering of the welding point. The

“Perfect-Point” mode is activated by touching the work piece to be welded with the tungsten tip, at the exact point

at which you wish to do the tack weld. Proceed as follows:

Loading...

Loading...