Operation

24

DTX-2200-3000 AC/DC

■ ELECTRODE DIAMETER

For TIG welding with HF ignition, it allows you to use the relevant key to set the diameter of the tungsten

electrode used, and/or to change it using the ENCODER knob, in order to achieve the best control of the

AC arc in a synergic manner.

WARNING: The electrode diameter CANNOT be selected when the welding machine is set for the SPECIAL

configuration.

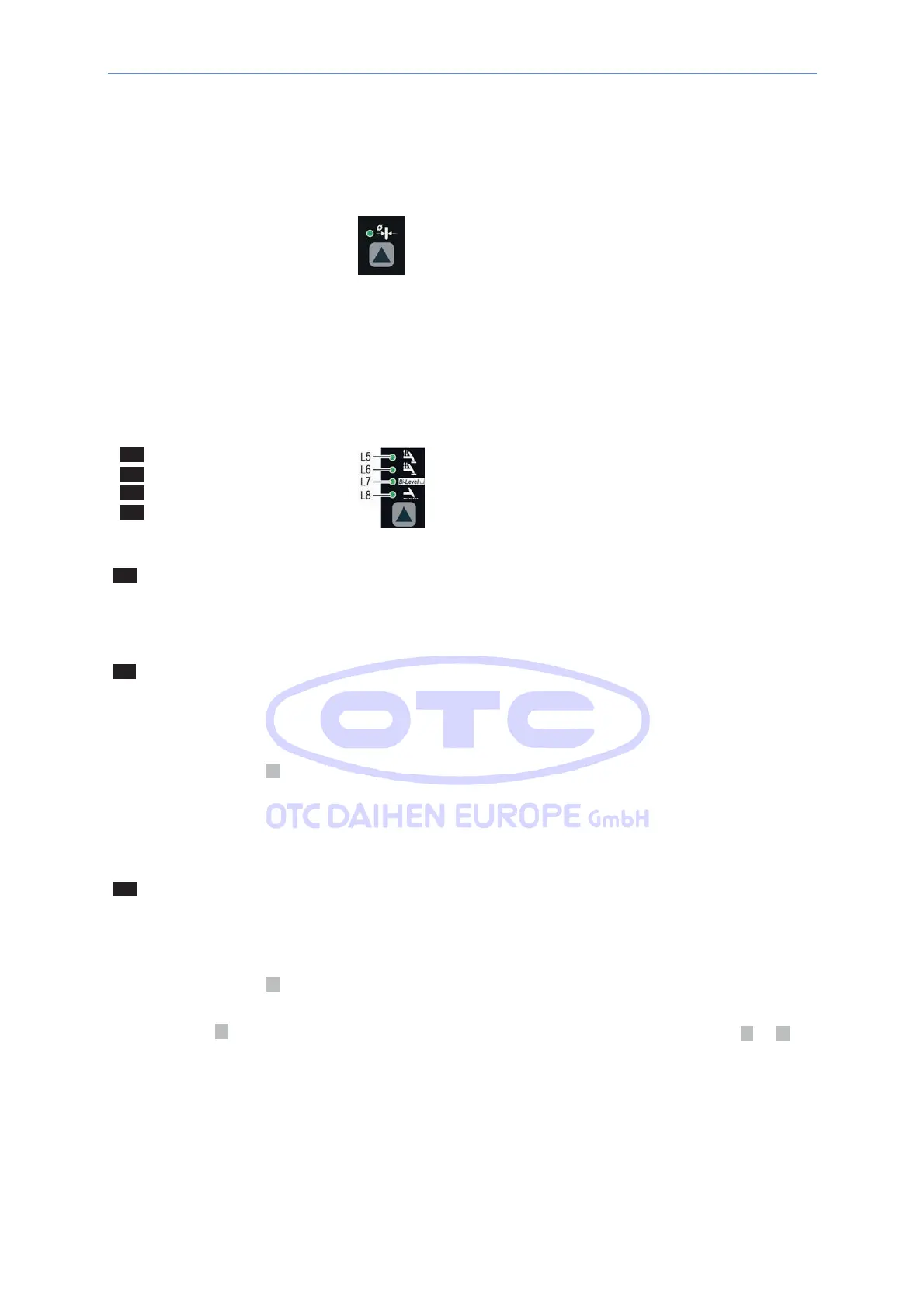

■ WELDING MODE

The DTX welding machine offers 4 welding modes. Each time the button is pushed, the welding machine switches

to select the welding mode indicated by the LED that stays lit, in the following order:

L5 2

STROKES

L6 4

STROKES

L7

Bi-Level

L8 SPOT

WELDING

L5 2 STROKES

When the torch button is pushed welding begins starting with the INITIAL CURRENT (if SLOPE UP is selected),

while when it is released welding ends when the FINAL CURRENT is reached (if SLOPE DOWN is set).

L5 4 STROKES

TIG welding takes place as follows:

• When the torch button is pushed welding begins at the INITIAL current.

• When the torch button is released the SLOPE UP process is carried out (if applicable) and the current returns to

the PRINCIPAL value I

1

.

• When the torch button is pushed the SLOPE DOWN process is carried out (if applicable) and the current returns

to the FINAL value.

• When the button is released the welding Bi-Level ends.

L7 Bi-Level

When this function has been activated, TIG welding takes place as follows:

• When the torch button is pushed welding begins at the INITIAL current.

• When the torch button is released the SLOPE UP process is carried out (if applicable) and the current returns to

the PRINCIPAL value I

1

.

• When the torch button is pressed and released within less than 1 second the welding current goes to the Bi-

Level value ( I

2

), and by repeating this operating you can move between the two current levels ( I

1

), ( I

2

) an

infinite number of times.

• When the torch button is pushed and held down (for longer than 1 second) you exit the cycle, the SLOPE DOWN

process is carried out (if applicable) and the current returns to the FINAL value. When the torch button is released

the welding cycle ends. This welding mode is especially indicated for welding profiles with different thickness,

where continuous current variation is required. Also, when welding aluminum, it allows you to have a higher initial

current, thereby facilitating pre-heating of the work piece

Loading...

Loading...