Operation

53

DTX-2200-3000 AC/DC

2200 AC/DC 3000 AC/DC

TIG DC 5 - 220 A 5 - 300 A

TIG

AC

DYNAMIC TIG

SPEED TIG

COLD TIG

SOFT TIG

5 - 220 A

5 - 220 A

16 - 127 A

16 - 156 A

5 - 300 A

5 - 300 A

5 - 173 A

5 - 212 A

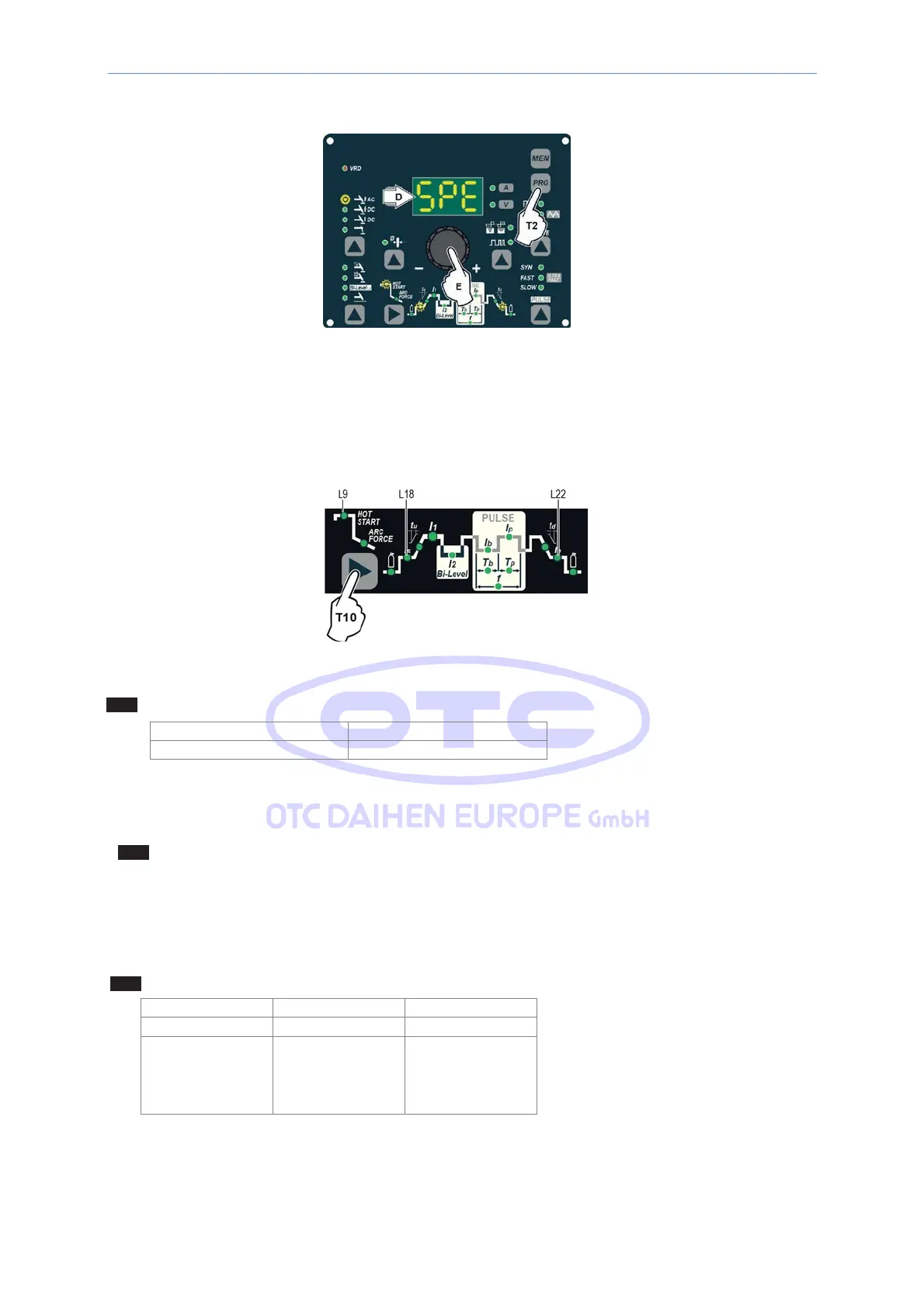

5) Press the “PRG” PROGRAM key (T2) to confirm.

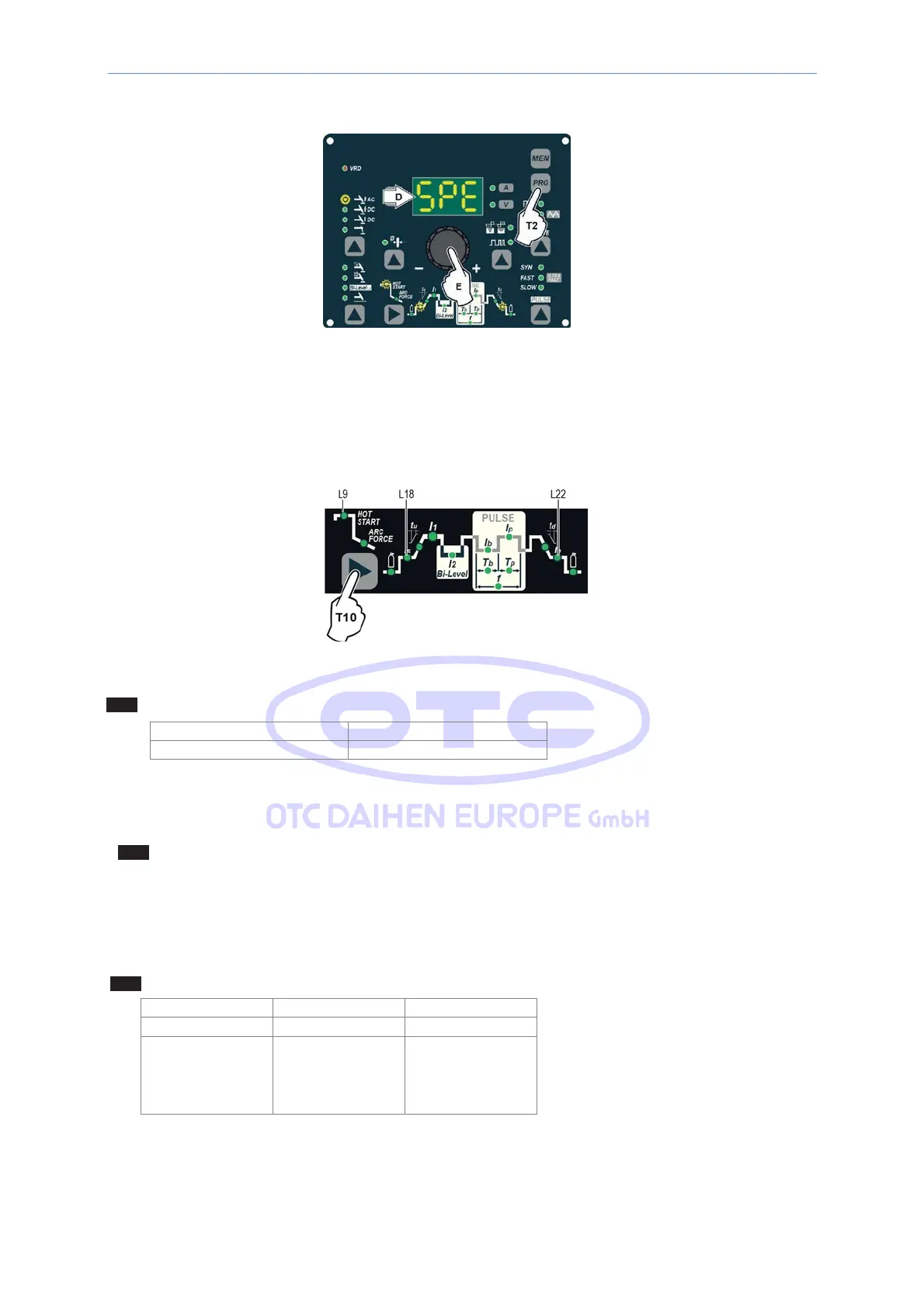

The WELDING PARAMETERS included, that can be programmed and changed (by turning the ENCODER

knob) in the SPECIAL (SPE) configuration, along with those in the STANDARD configuration, can be set by

pushing the WELDING PARAMETER SELECTION button (T10) successively:

L9 IGNITION CURRENT

2200 AC/DC 3000 AC/DC

5 - 220 A 5 - 300 A

WARNING: This can only be programmed for TIG AC with HF

ig

nition - TIG DC with HF

ignition

welding

processes.

L9 IGNITION TIME duration (t.01 (0,01 sec) - t.50 (0,50 sec))

WARNING: This can only be programmed when the TIG AC with HF ignition welding process is active.

WARNING: If the value of these 2 parameters is too low, this could prejudice ignition.

L18 IGNITION welding CURRENT

WARNING: This can only be programmed when the TIG AC

with

HF

ignition

or TIG DC with HF

ignition

welding processes and the 2 STROKES welding mode are used.

Loading...

Loading...