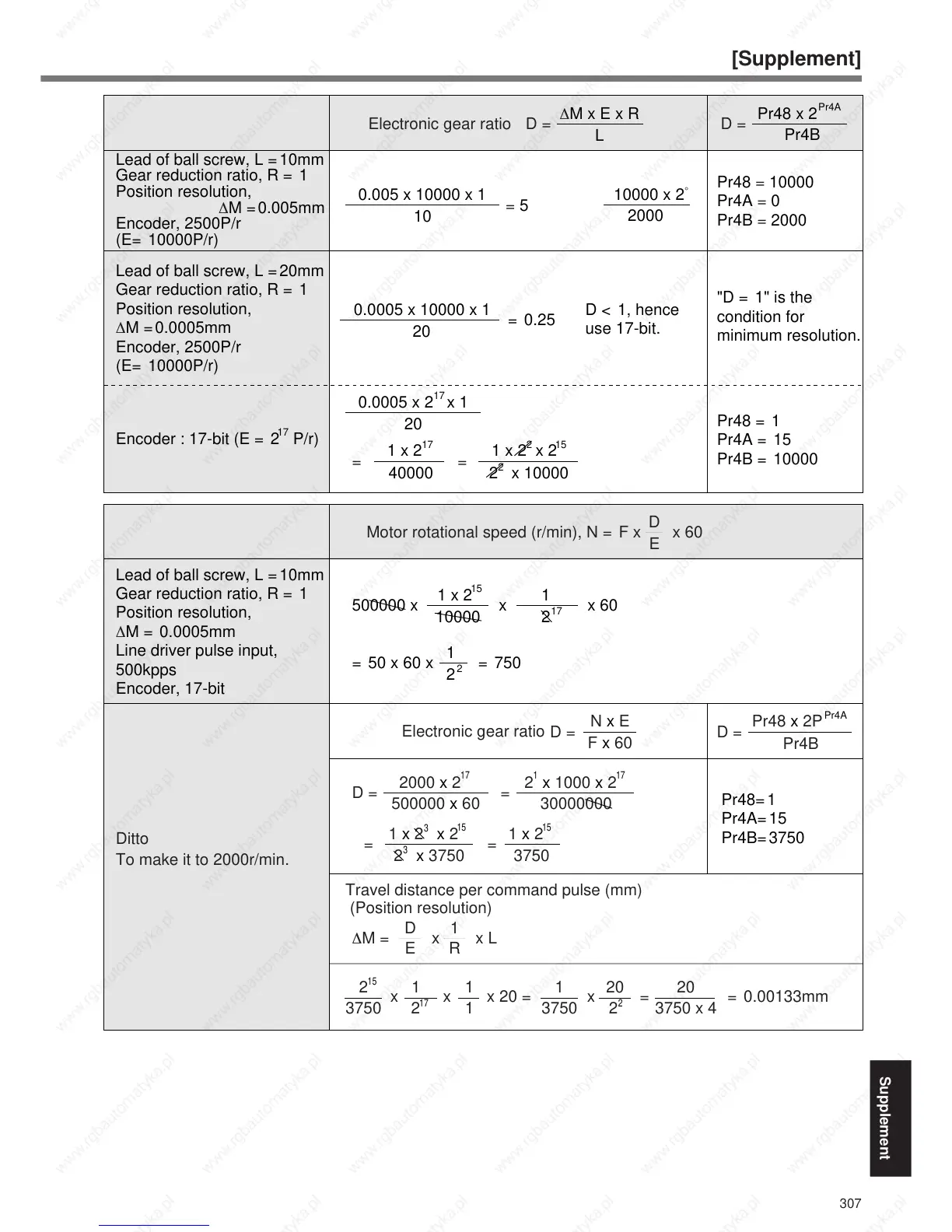

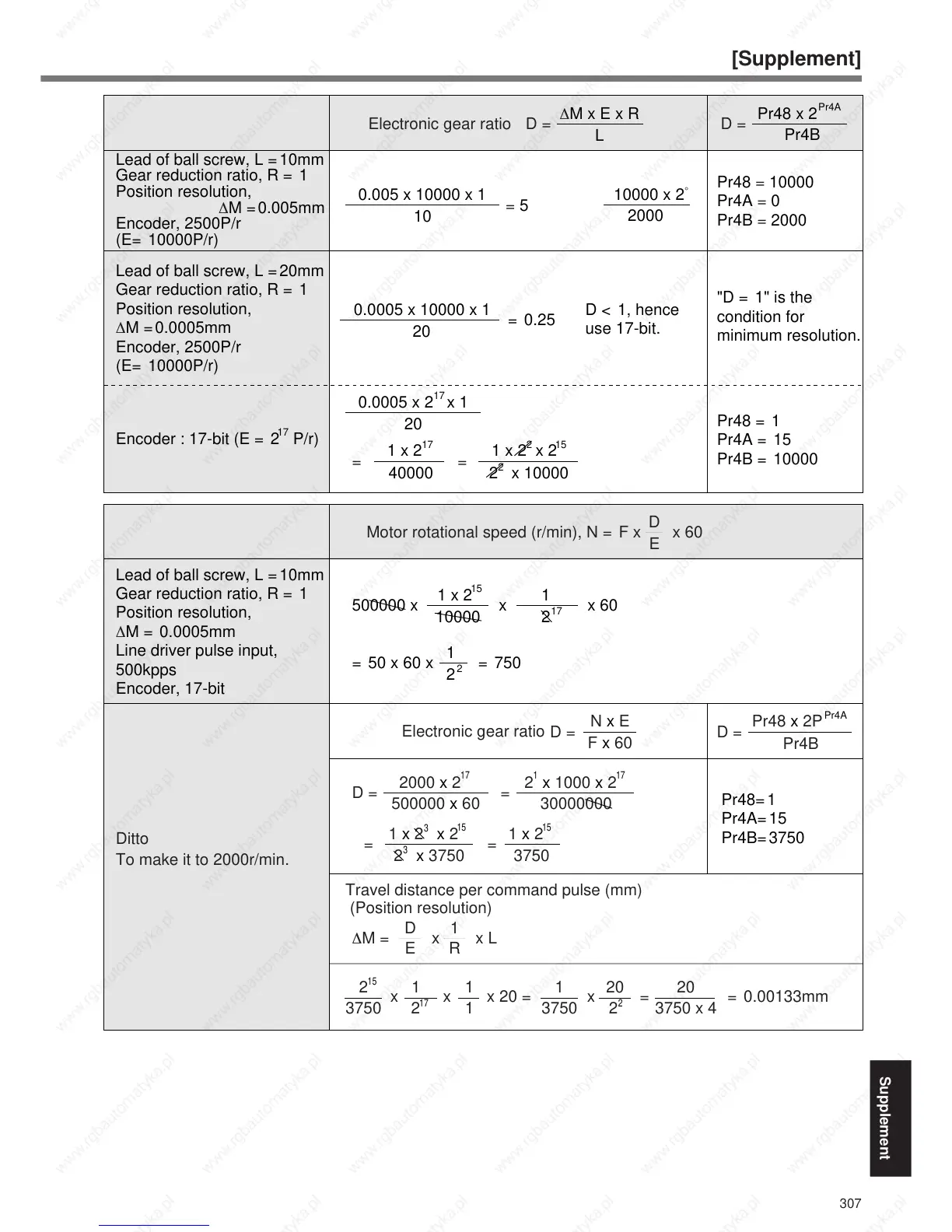

Electronic gear ratio

= 5

10

0.005 x 10000 x 1

= 0.25

20

0.0005 x 10000 x 1

20

0.0005 x 2 x 1

= =

40000

1 x 2

2 x 10000

1 x 2 x 2

D < 1, hence

use 17-bit.

D =

L

∆M x E x R

Electronic gear ratio

Travel distance per command pulse (mm)

(Position resolution)

D =

F x 60

N x E

"D = 1" is the

condition for

minimum resolution.

Pr48 = 10000

Pr4A = 0

Pr4B = 2000

Pr48 = 1

Pr4A = 15

Pr4B = 10000

Pr48=1

Pr4A=15

Pr4B=3750

D =

Pr4B

Pr48 x 2

2000

10000 x 2

°

Motor rotational speed (r/min), N = F x x 60

E

D

17

17 2

2

15

= 50 x 60 x = 750

2

1

500000 x x x 60

10000

1 x 2

15

17 17

2

∆M = x x L

E

D

R

1

D = =

500000 x 60

2000 x 2

1

3

3

30000000

2 x 1000 x 2

15

2

1

1

1

x x x 20 = x = = 0.00133mm

3750

2

15

17

2

20

3750

1

2

3750 x 4

20

15

= =

2 x 3750

1 x 2 x 2

3750

1 x 2

2

1

17

Lead of ball screw, L =10mm

Gear reduction ratio, R = 1

Position resolution,

∆M =0.005mm

Encoder, 2500P/r

(E= 10000P/r)

Lead of ball screw, L =20mm

Gear reduction ratio, R = 1

Position resolution,

∆M =0.0005mm

Encoder, 2500P/r

(E= 10000P/r)

Lead of ball screw, L =10mm

Gear reduction ratio, R = 1

Position resolution,

∆M = 0.0005mm

Line driver pulse input,

500kpps

Encoder, 17-bit

Ditto

To make it to 2000r/min.

Encoder : 17-bit (E = 2

17

P/r)

Pr4A

D =

Pr4B

Pr48 x 2P

Pr4A

Loading...

Loading...