Microdrive Series Instruction Manual

4201-109 Rev I

65

52 VOLTAGE LIMIT SLIP

Screen 52 VLT SLIP=2.0%*

Description VOLTAGE LIMIT SLIP

Min/Max 0.0/9.9

Units %

* This value is dependent on Microdrive current rating.

FUNCTION If a motor is overdriven (e.g., by decelerating

its attached load too fast) it will regenerate into

the Microdrive. Too much regeneration will

cause the Microdrive to take evasive action

(voltage limiting) by reducing the deceleration

rate as regeneration occurs.

The voltage limit slip setting is an adjustment

which is used to enhance the stability of

voltage limiting control by providing a motor slip

parameter.

SETTING UP Do not adjust this setting unless voltage limiting

is unstable. Nominally this value should be set

to the rated percent slip of the motor (see

Screen 46 to calculate this value). To improve

stability of voltage limit use a lower value. The

penalty against this is that voltage limiting will

occur at an earlier stage, thus affecting

deceleration more.

The S-curve setting (Screen 17) may also be

used to improve stability during voltage limiting.

53 NO LOAD DAMPING

Screen 53 DAMPING=0.4%*

Description NO LOAD DAMPING

Min/Max 0.0/5.0

Units %

* This value is dependent on Microdrive current rating.

FUNCTION Some motors may become unstable and appear

to surge when operated at light load and at

certain speeds. The damping term may be

introduced to eliminate this tendency.

SETTING UP Do not adjust this value unless light load

stability problems exist.

Increase setting to improve stability. Increasing

the setting too far may induce instability.

The setting is nominally equal to 20% of the

calculated percentage motor slip (see Screen

46).

No load damping introduces very small output

frequency variations (typically <0.1 Hz). If

absolute fixed output frequency is a specific

requirement of your application, set to 0.0%.

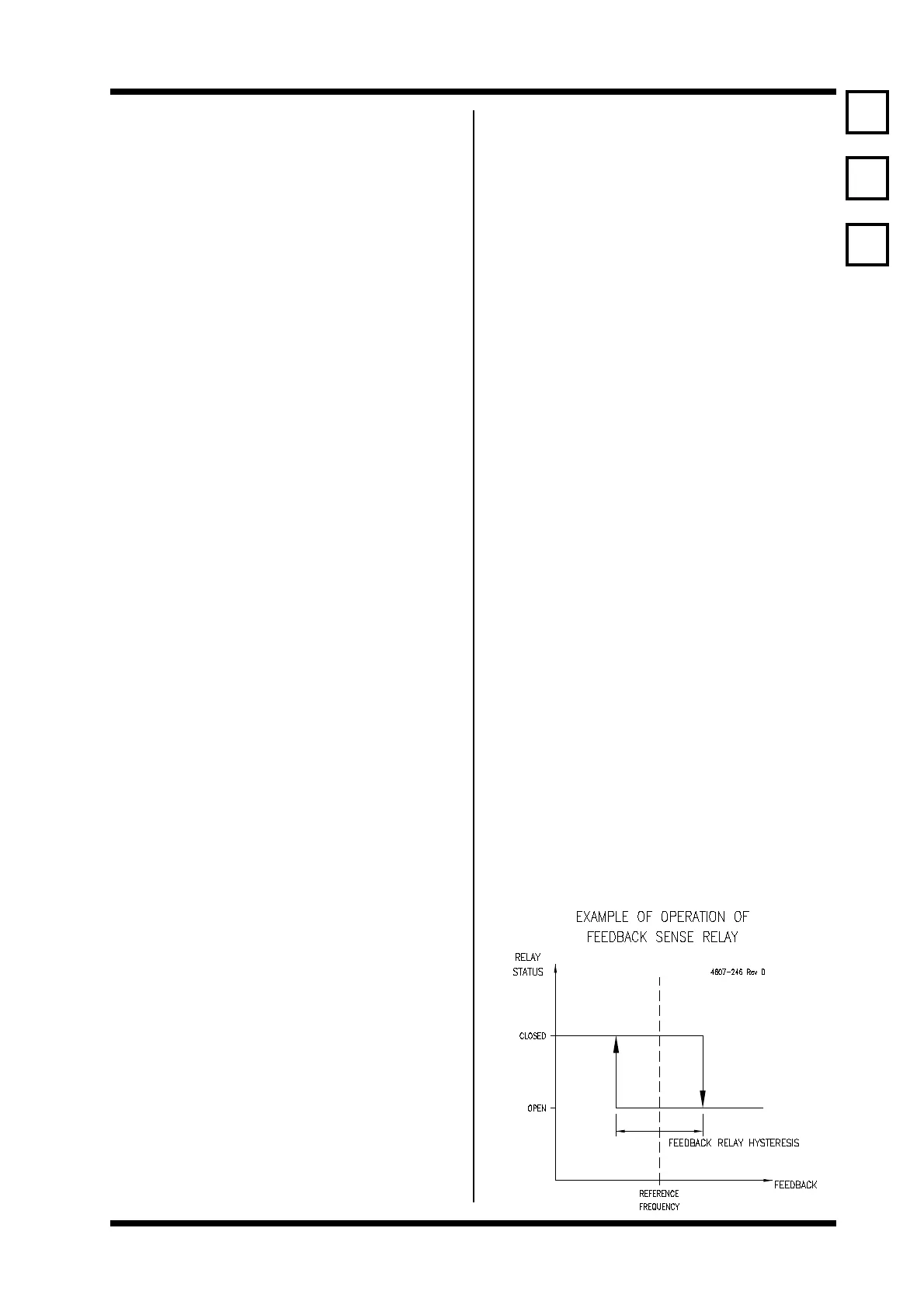

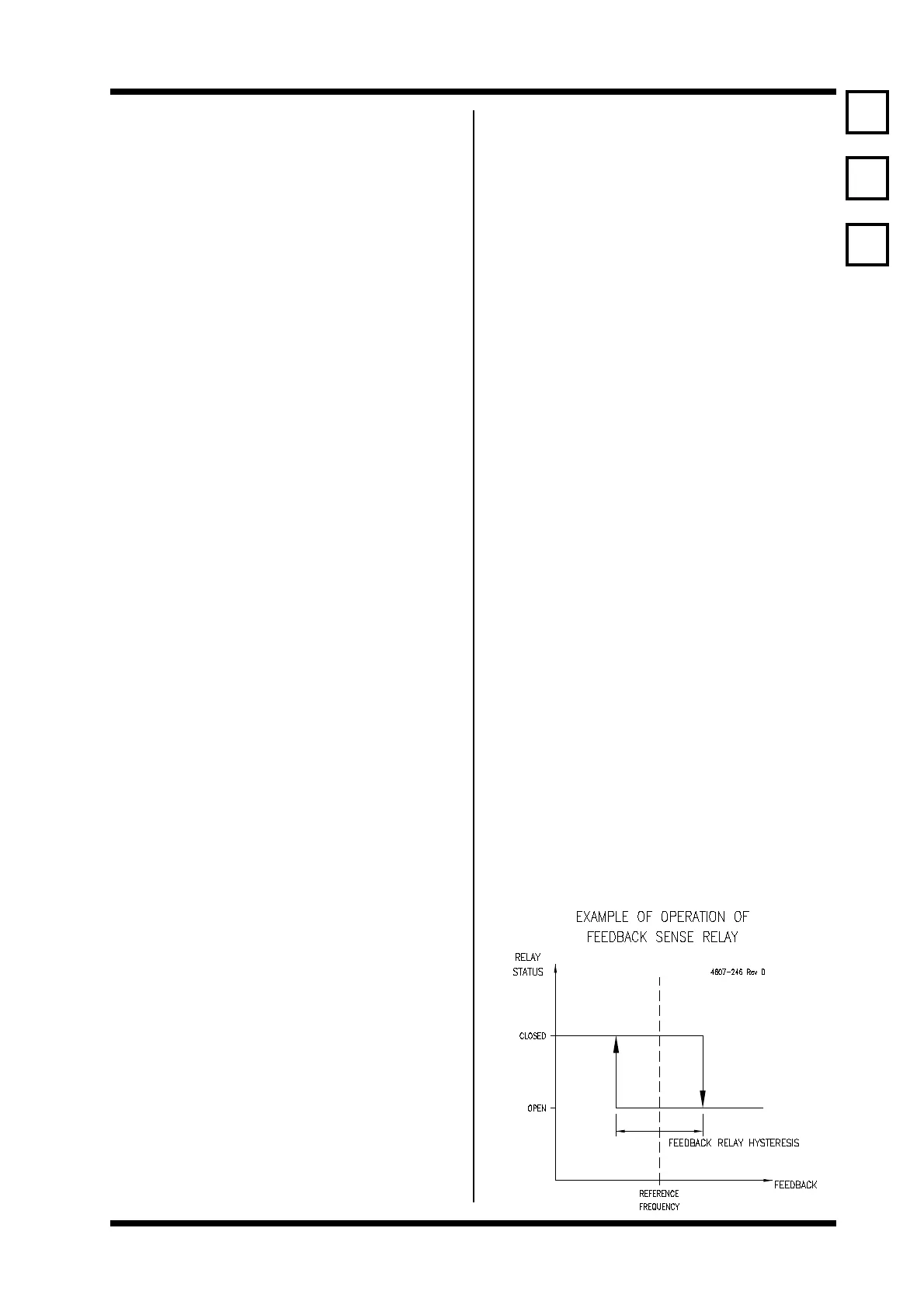

54 FEEDBACK SENSE RELAY HYSTERESIS

Screen 54 FB RLY = 10.0 Hz

Description FEEDBACK SENSE RELAY HYSTERESIS

Min/Max 0/200

Units HERTZ

FUNCTION T o set the operating points of the feedback

sensing relay. This relay is useful to show that

a feedback process is operating correctly and

is at its setpoint.

A feedback input signal higher than the

reference setpoint plus half the hysteresis

frequency set in this function will de-energise

the selected relay.

When the feedback drops below the reference

minus half the hysteresis frequency the relay

will re-energise.

Equations for relay output:

Relay open

Feedback > reference + ½ hysteresis

Relay closed

Feedback < reference ½ hysteresis

SETTING UP The feedback sense relay hysteresis is not

used unless the Microdrive is configured for

process control (feedback) operation.

Set the relay hysteresis to the value required by

your feedback process.

Configure the relay output using Screens 67,

68, 69.

EXAMPLE Reference = 50 Hz

Hysteresis = 10 Hz

Relay open

Feedback > 50 Hz + 5 Hz

Relay closed

Feedback < 50 Hz 5 Hz

Note: Refer example in Appendix 4D - Application

Example - Constant Pressure Pumping with

Automatic Start/Stop Control.

52

53

54

Loading...

Loading...