Microdrive Series Instruction Manual

4201-109 Rev I

26

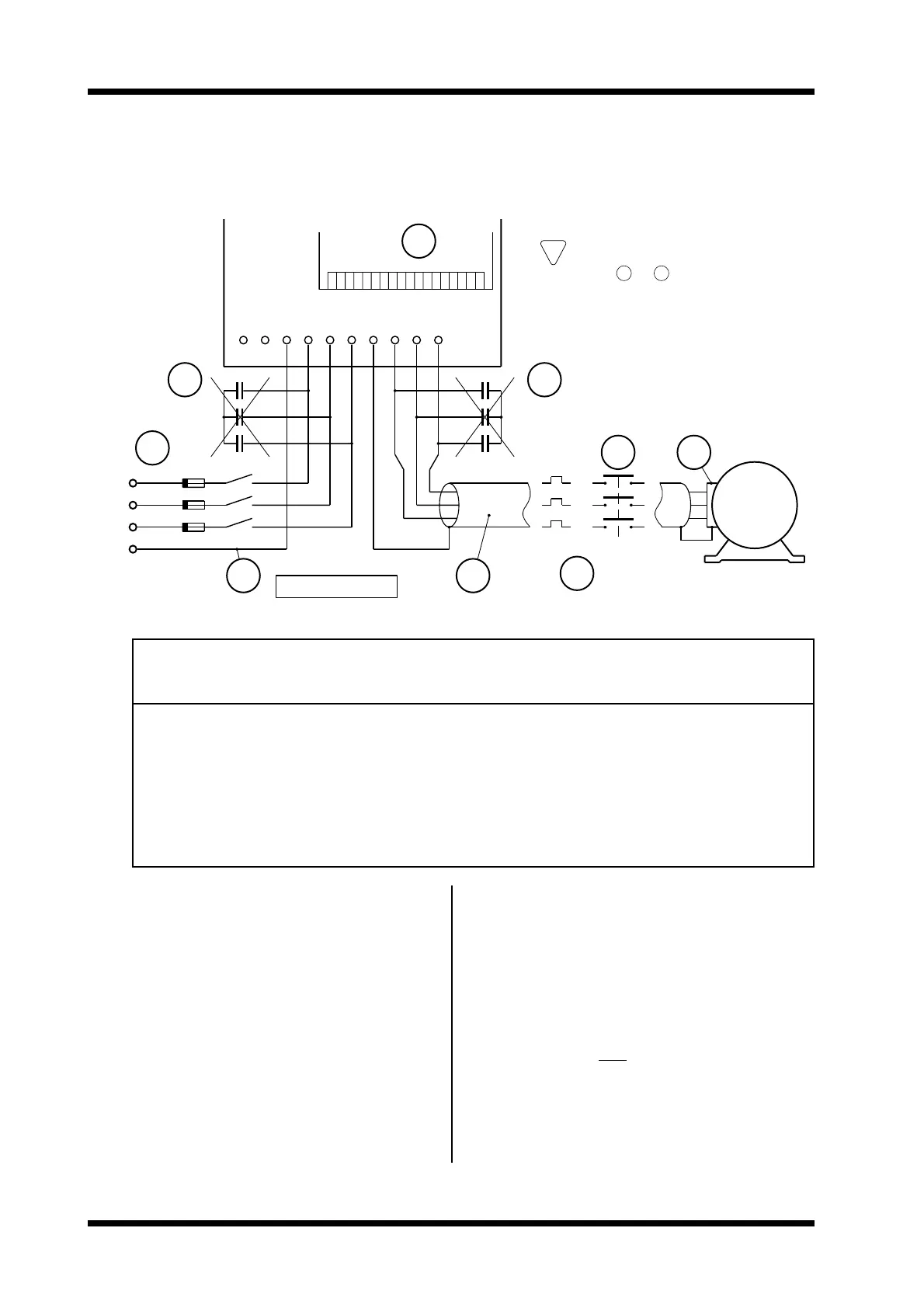

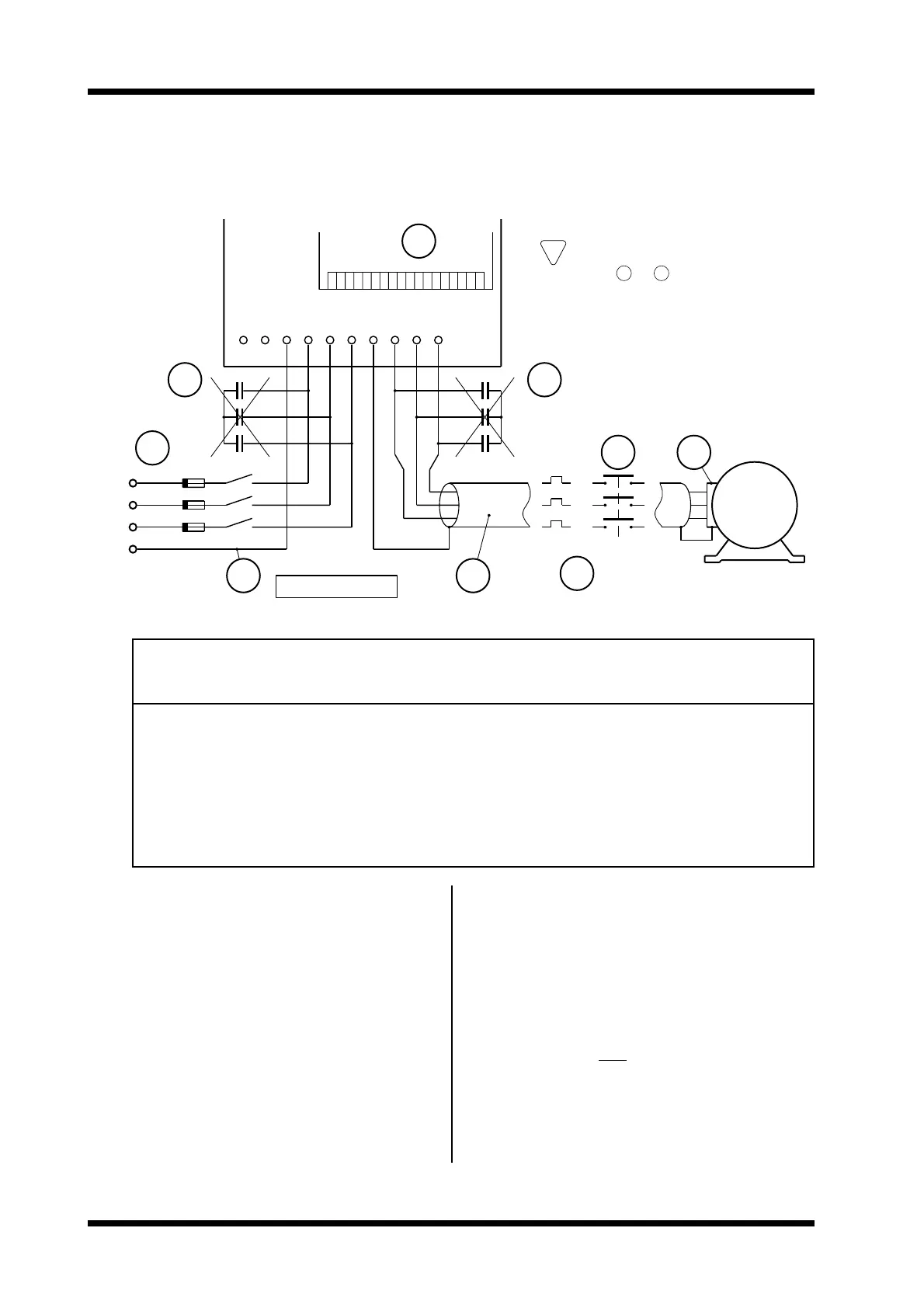

WARNING:

ENSURE SUPPLY IS ISOLATED

BEFORE WIRING UP

W

NO!

L3

E

L2

L1

4807−021 Rev E

F3

6

F1

F2

1

E

2

DC

+

−

L2L1

L3 U

EV

7

NO!

5

4

3

5

M

WARNING:

READ NOTES TO

BEFORE CONNECTING TO

POWER TERMINALS

2

!

1

8

1. Wiring Details:

UD3 RATED FUSE RECOMMENDED POWER TERMINAL

MODEL CURRENT (Q1) CABLE SIZE TERMINAL TIGHTENING

TYPE TORQUE

AA mm

2

Nm

2.5 2.5 6 2.5 SLEEVE 1.5

6.5 6.5 10 2.5 SLEEVE 1.5

10.5 10.5 16 2.54.0 SLEEVE 1.5

12 12.0 20 2.54.0 SLEEVE 1.5

16 16.0 20 2.54.0 SLEEVE 1.5

22.5 22.5 30 4.06.0 SLEEVE 1.5

31 31.0 40 6.010.0 LUG 4.0

46 46.0 60 10.016.0 LUG 4.0

60 60.0 80 25.035.0 LUG 4.0

70 70.0 80 25.035.0 LUG 4.0

be isolated before operating on the motor terminals.

6. The UD3 output switching voltage waveform can

give rise to high (capacitive) earth leakage currents.

Permanent earth connection of both the motor and

the UD3 is essential before connection to the

supply.

7. The control input circuit is configurable from the

keyboard. Be sure that you are using the correct

configuration and circuit before wiring up. Good

control circuit wiring practice should be observed.

Control wiring must be screened and run physically

separate from power wiring (at least 300mm

distance and crossing only at right angles).

8. The location and order of the power terminals

varies from model to model. Refer to the terminal

labels before connection.

2. Power factor capacitors are not required on the

UD3 input (UD3 pf = .95), and must not be

connected to the UD3 output.

3. A motor isolator or contactor may be used on the

UD3 output, but its use should be restricted to

emergencies.

4. Where radio frequency interference may be a

problem, screened cable (e.g., neutral screen, steel

conduit) must be used on the UD3 output. Bond

the screen solidly to the UD3 and motor chassis.

The output cables should be run separate from the

input cables (especially if not screened).

5. The UD3 protects the motor with an electronic

overload, so an external overload relay is

unnecessary. Where multiple motors are

attached, separate overload protection should be

applied to each motor. The UD3 or the motor must

Figure 1.4a Microdrive-3 (UD3) Recommended Power Wiring Instructions

Loading...

Loading...