Microdrive Series Instruction Manual

4201-109 Rev I

100

Adjustment 24 FR F2

(Default) (=+60.0Hz)

Setting 60.0

Notes Set equal to MAX FR.

Adjustment 43 T GAIN

(Default) (=20.0)

Setting 2.0

Notes Calculated according to instructions in the

detailed description of Screen 43:

Encoder frequency at 50Hz = 1500 (rpm) x 1000 (ppr)

60 (secs)

= 25 kHz

Tacho gain = 50 (Hz)

25 (kHz)

= 2.0 (Hz/kHz)

MODES

Mode 64 REF FR

(Default) (= 010V)

Setting 420mA

Notes Selects 420mA as the reference source.

Mode 65 FB SRC

(Default) (=O/LOOP)

Setting TACHO

Notes Selects tacho feedback mode.

Mode 66 I/P MODE

(Default) (=01)

Setting 01

Notes Sets the multi-function inputs up for three wire

control.

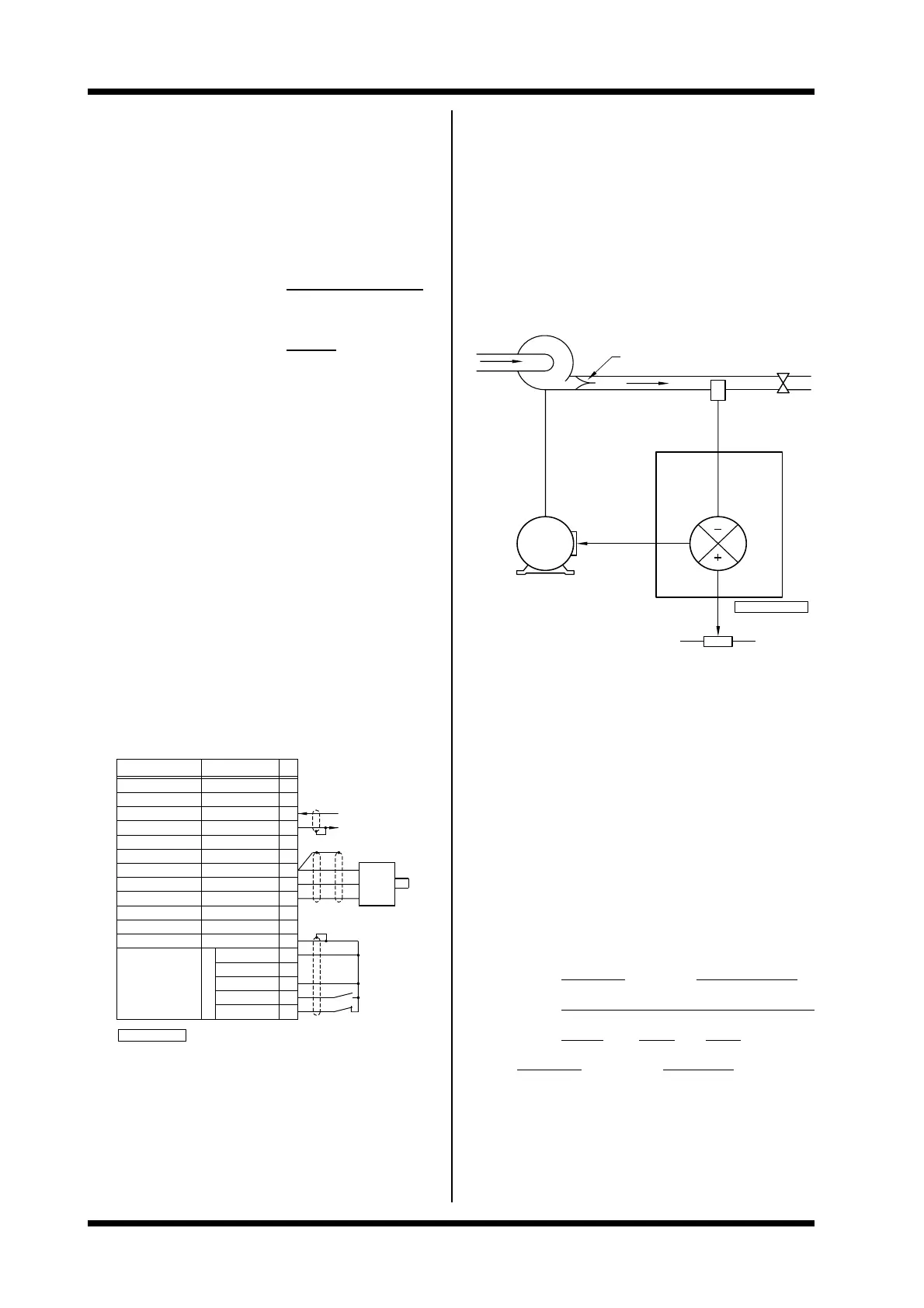

1000PPR

14MOTOR PTCMOTOR PTC

MODE = 1

4807−076 Rev E

SWITCH INPUT 2

SWITCH INPUT 1

0V

SWITCH INPUT 5

SWITCH INPUT 4

SWITCH INPUT 3

START

STOP

8

9

EMERGENCY STOP

DIRECTION INVERT

STOP/RESET

0V

12

11

10

13

EXAMPLE: TACHO CONTROL

WIRING CONFIGURATION

+10V POTENTIOMETER

0V

TACHO INPUT

TACHO SUPPLY

0V

FREQUENCY OUTPUT

FREQUENCY INPUT

0V

FREQUENCY INPUT

0−10V ANALOGUE O/P

I/O NAME

PDL ENCODER 0300−EN

19

SUPPLY

TACHO INPUT

+12V/50mA MAX

0V

0V

15

16

18

17

0V/−mA

0−10V

+ 4−20mA

F = 26.25 F

21

20

O/P

22

23

+V

0V

A

SOURCE

0−10V=0−100Hz

FUNCTION

24

4−20mA

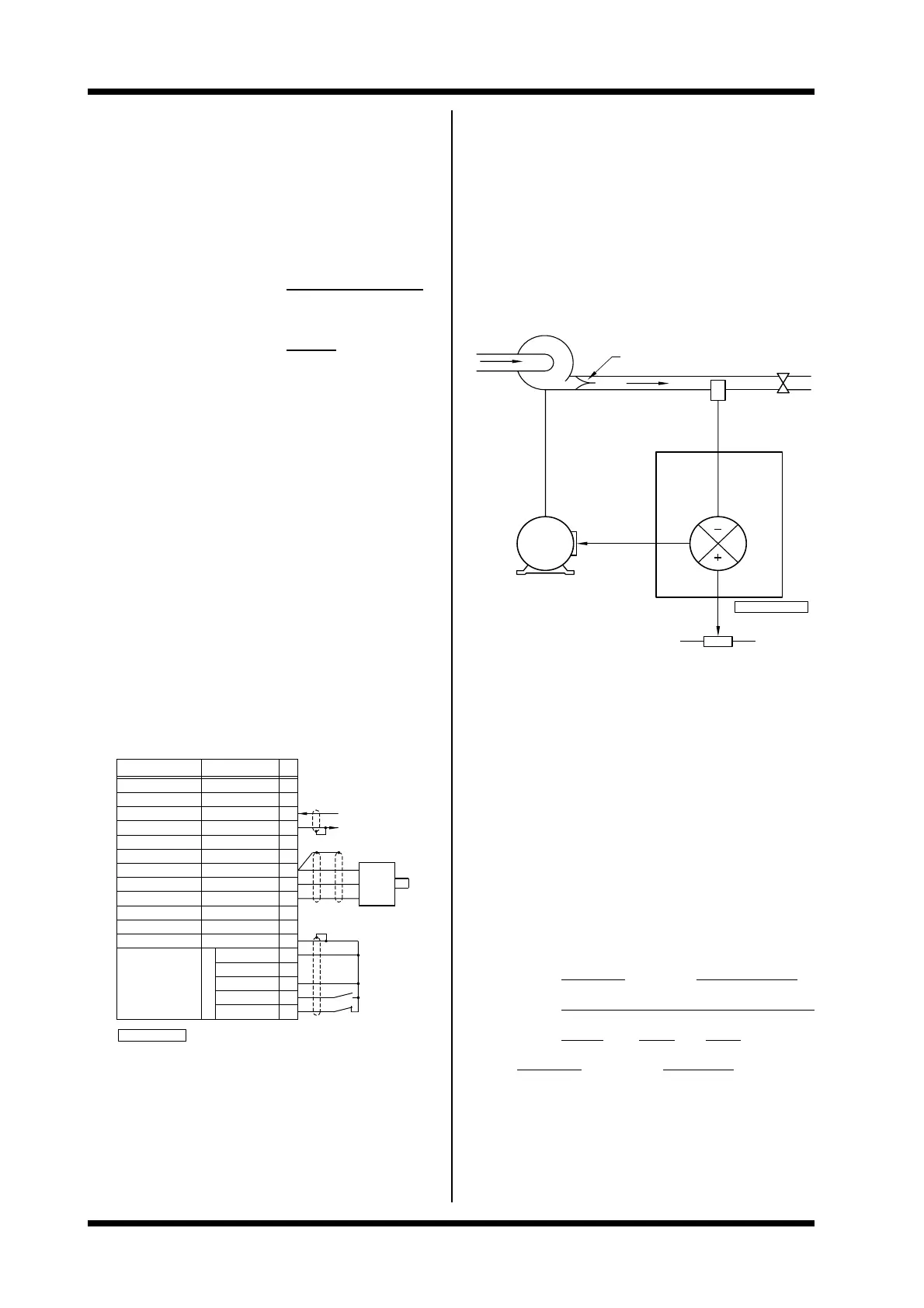

4C: APPLICATION EXAMPLE -

CONSTANT PRESSURE PUMPING

Constant pressure pumping is a common application of AC

Motor Speed Controllers. This appendix shows the

configuration, wiring and adjustment of a typical example.

Constant pressure pumping systems maintain the pressure of

the outgoing pipe by controlling the speed of the pump. If the

demand increases (e.g., opening a tap) the pressure de-

creases and the pump has to wind up the speed. The system

pressure is used as a feedback signal. The output pressure is

selected with the setpoint potentiometer.

M

4807−247 Rev D

DRIVE

SET PRESSURE

PRESSURE

SENSOR

FEEDBACK

NON−RETURN VALVE

TAP

The example given is of a system of the following specification:

Control signal 010V (potentiometer)

Pressure sensor 420mA, 100psi,

12V supply, 3 wire

Motor 132 kW, 245A,380V,

1485 rpm

Microdrive model 250

Stop/start control 2 wire

Direction control reverse inhibited

The configuration table (not including irrelevant and/or settings

which have not been altered from factory set values) and

wiring configurations follow:

CONSTANT PRESSURE PUMPING EXAMPLE

CONFIGURATION TABLE

DRIVE NO: _________ MODEL:____UDi-250____

SITUATION: __Constant Pressure Pump_______________

MOTOR kW: _132__ A:_245_ V:_380_

POLES:____4____ RPM:__1485____

Loading...

Loading...