Microdrive Series Instruction Manual

4201-109 Rev I

108

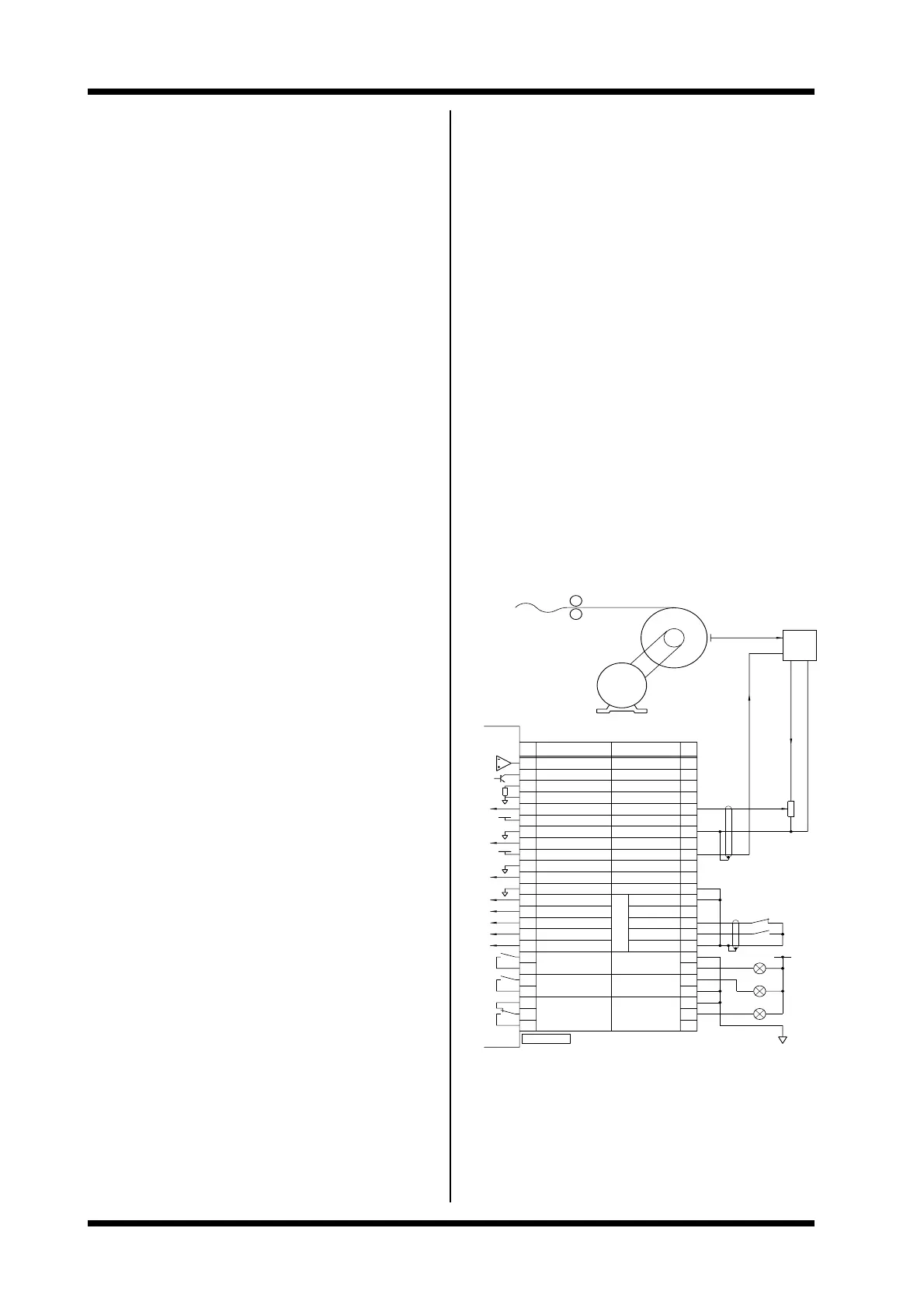

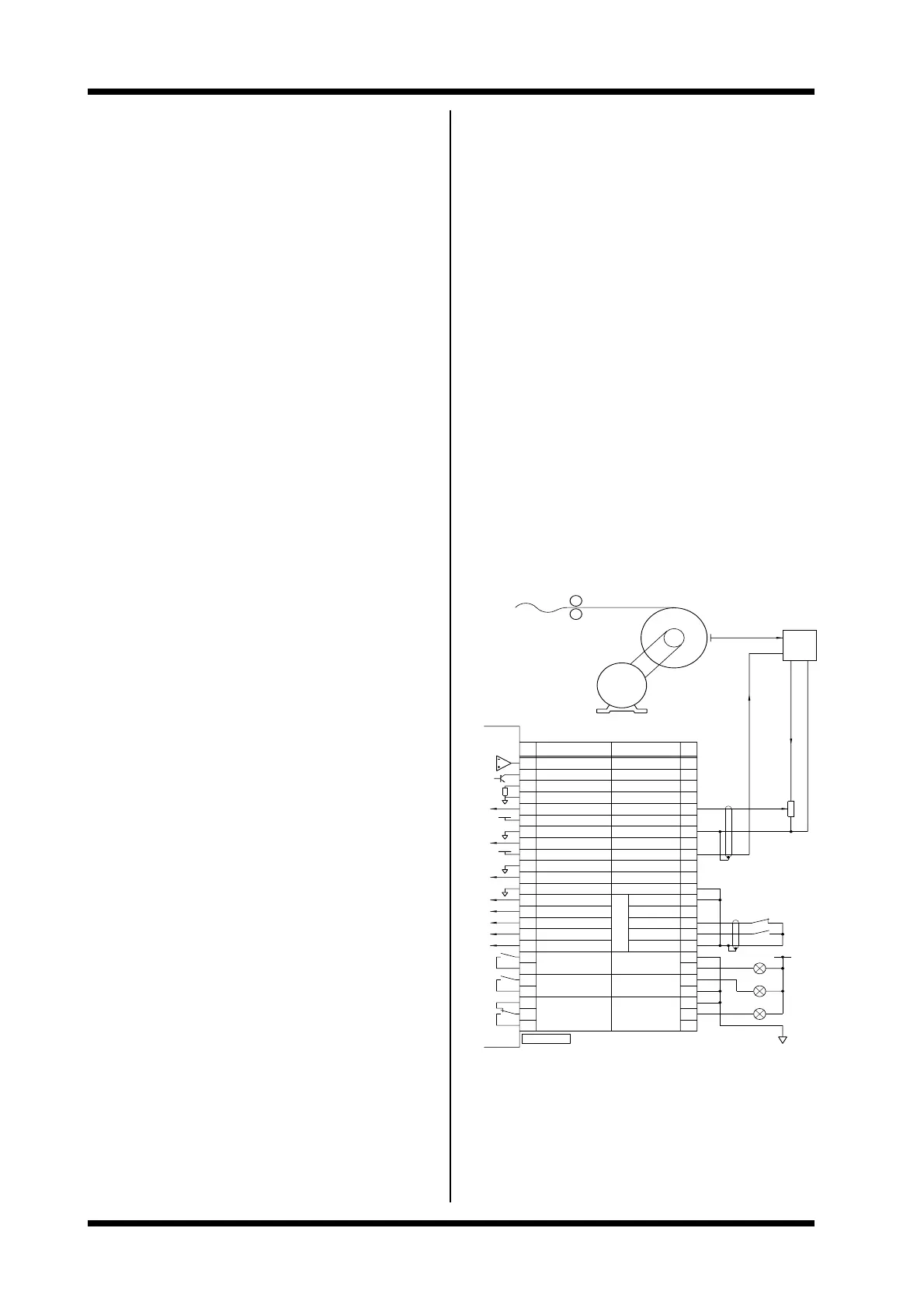

6B: APPLICATION EXAMPLE -

CONSTANT TENSION WINDER

SPECIFICATION:

Material is to be wound onto a reel at constant tension.

Tension is to be adjustable but independent of the rate of material

production and radius of the roll.

Tension control set point 1kohm pot

Maximum roll speed 1200 rpm

Minimum roll speed 300 rpm

Torque range 150Nm - 700Nm

Stop/start control 3 wire

Motor 132kW, 245A, 380V

Special requirements Stalled/jammed product

indication, loss of product/

loss of tension indication.

Operate the drive under torque limit with the torque limit adjusted

proportionally with the radius of the roll to provide constant

tension.

Use the frequency sense relay to indicate that the rotation is too

low (i.e., product stalled).

Use the AT FREQUENCY relay to indicate that the drive is

operating at the limit frequency (loss of product continuity).

ADJUSTMENTS :

Adjustment 10 MTR CUR

Set-up 245A

Notes -

Adjustment 11 MTR VOLT

Set-up 380V

Notes -

Adjustment 14 BOOST

Set-up 2.0%

Notes Needs to be set to give accurate torque at low

speed.

Adjustment 20 ILT SLIP

Set-up 1%

Notes This screen controls the current limit stability. If

set too high or to OFF the controller may surge.

Adjustment 25 MIN FLUX

Set-up 100%

Notes Full flux is needed for accurate linear control.

Adjustment 29 FR ON

Set-up 10Hz (300 rpm)

Notes Sense frequency for stall detection.

Adjustment 30 FR OFF

Set-up 9.0Hz

Notes Sense frequency for stall detection.

Adjustment 64 REF FR SEL

Set-up KEYBD

Notes The frequency setpoint is set by the keyboard

and is there to limit the speed if the tension is

released.

Adjustment 66 I/P MODE

Set-up Input Mode 1

Notes 3 wire start/stop with reset.

Adjustment 67 O/P RELAY 1

Set-up 0 = Fail-safe Fault

Notes Drive fault indicator.

Adjustment 68 O/P RELAY 2

Set-up 6 = Frequency Sense

Notes Stall indicator.

Adjustment 69 O/P RELAY 3

Set-up 10 = At Set Frequency

Notes No load indicator.

Adjustment 75 I LIM MODE

Set-up TQ

Notes Current limit on real current for linear torque

control.

Adjustment 76 I LIM SRC

Set-up 010V

Notes Use the 010V signal for torque reference.

Adjustment 77 AUTOBOOST

Set-up YES

Notes Use autoboost to maintain constant motor flux

at low speeds. This ensures accurate torque

limit control.

FREQUENCY

FREQUENCY

EM.STOP

STOP/RES

START

MOTOR PTC

+12V/50mA MAX

TACHO INPUT

0−10V=0−100Hz

4807−174 Rev D

1

2

3

RELAY 1

OUTPUT

FAULT

FAILSAFE

+12V

+10V

12

SWITCH INPUT 5

SWITCH INPUT 1

SWITCH INPUT 2

SWITCH INPUT 3

SWITCH INPUT 4

8

4

5

7

6

RELAY 2

OUTPUT

RELAY 3

OUTPUT

10

9

11

STOP

SENSE

AT SET

MODE = 1

DIRN

MOTOR PTC

TACHO SUPPLY

TACHO INPUT

+10V POTENTIOMETER

FREQUENCY INPUT

14

13

15

16

0V

0V

17

18

19

20

0V

0V

0V

0V

SUPPLY

0−10V

PROCESS PRODUCT

250R

FREQUENCY INPUT

FREQUENCY OUTPUT

0−10V ANALOGUE O/P

I/O NAME

23

22

21

24

0V

FUNCTION

F = 26.25 F

0V/−mA

+ 4−20mA

MOTOR

SET

0V

FAULT

1

2

3

STALL

NO LOAD

START

STOP/RESET

12

8

4

5

7

6

10

9

11

+

14

13

15

16

17

18

19

20

DIAMETER

SUPPLY

23

O/P

22

21

24

SIGNAL

TENSION

OUTPUT

DIAMETER

+12V

REEL

GUAGE

Loading...

Loading...